Impurity of neomycin sulfate and preparation method thereof

A technology of neomycin sulfate and impurities, which is applied in the field of medicine and chemical industry, can solve problems such as not being found, and achieve the effect of guaranteeing and controlling quality and improving quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

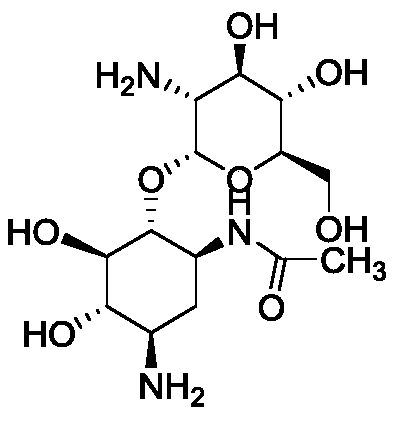

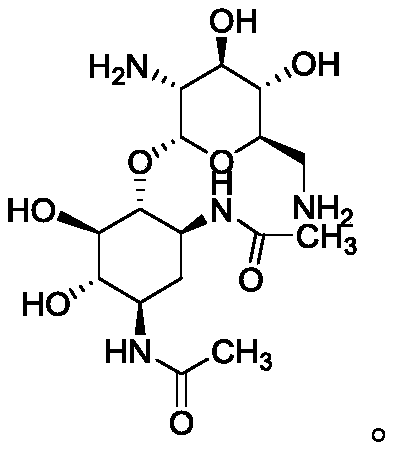

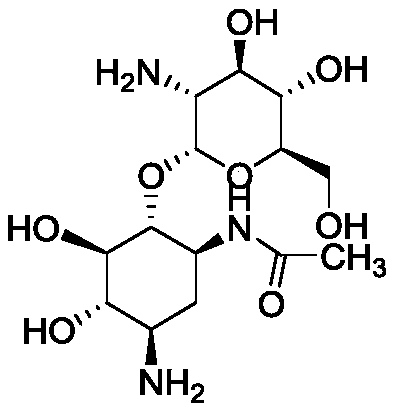

Image

Examples

Embodiment 1

[0043] Take a 50mL dry three-necked glass reaction bottle, under the protection of nitrogen, add 200mg of neomycin impurity D and 10mL of ethyl acetate solvent, stir and dissolve evenly, put it in an ice bath at 0°C, take 0.029g of acetyl chloride and dissolve it in 10mL of dry ethyl acetate The ester solution was slowly added dropwise, and the drop was completed within about 10 minutes. The reaction was maintained at this temperature for about 1 hour, and monitored by HPLC until the end. The reaction mixture was spin-dried at low temperature and separated by preparative chromatography to obtain 16.2 mg of the product with a purity of 95.9% and a yield of 8.1%.

Embodiment 2

[0045] Take a 50mL dry three-necked glass reaction bottle, under the protection of nitrogen, add 200mg of neomycin impurity D and 10mL of dry solvent ethyl acetate, stir and dissolve evenly, put it in an ice bath at 0°C, take 0.046g of acetyl chloride and dissolve it in 10mL of dry acetic acid The ethyl ester solution was slowly added dropwise, and the drop was completed within about 20 minutes, then 0.008 g of DMAP was added, and the temperature was maintained for about 3 hours, and the HPLC monitoring was completed. The reaction solvent was spin-dried at low temperature and separated by preparative chromatography to obtain 54 mg of the product with a purity of 95.9% and a yield of 27.0%.

Embodiment 3

[0047] Take a 50mL dry three-necked glass reaction bottle, under the protection of nitrogen, add 200mg of neomycin impurity D and 10mL of dry solvent acetonitrile, stir and dissolve evenly, put it in an ice bath at 10°C, take 0.029g of acetyl chloride and dissolve it in 10mL of dry acetonitrile solution, Slowly add dropwise, and finish dropping within about 20 minutes. Add 0.045 g of tetrabutylammonium bromide dropwise, and then add 0.038 g of DMAP, keep the temperature for about 3 hours, and monitor by HPLC. The reaction solvent was spin-dried at low temperature, followed by preparative chromatographic separation to obtain 87 mg of the product with a purity of 98.8% and a yield of 43.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com