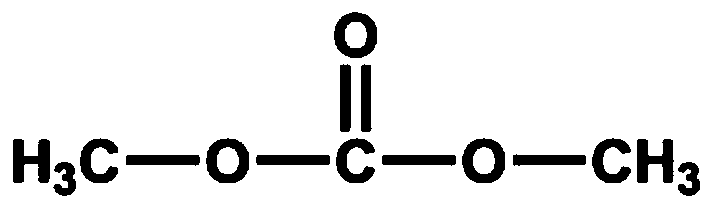

Reverse osmosis membrane based on dimethyl carbonate and preparation method thereof

A technology of dimethyl carbonate and reverse osmosis membrane, applied in the direction of reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of environmental protection, large co-solvent pollution, high reverse osmosis membrane flux, etc. To achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The surface of the polysulfone-based membrane was immersed in an aqueous phase solution containing 0.4% triethylamine, 2.0% camphorsulfonic acid and 1.4% m-phenylenediamine for 10 seconds to fully infiltrate the basement membrane with the aqueous phase solution. Subsequently, the solution was poured off. Next, after ensuring that there was no visible liquid on the surface of the membrane, the surface of the membrane was immersed in a n-heptane solution containing 0.04% trimesoyl chloride and 0.5% dimethyl carbonate to initiate interfacial polymerization. After reacting for 10 s, the membrane was heat-treated at 60°C for 1 min to prepare an aromatic polyamide composite reverse osmosis membrane, which was then fully washed with deionized water immediately.

[0041] The prepared reverse osmosis membrane is placed in the membrane test device, such as Figure 4 . The raw material liquid is a 2000 ppm sodium chloride aqueous solution. Before adding the raw material solutio...

Embodiment 2

[0043] The surface of the polysulfone-based membrane was immersed in an aqueous phase solution containing 0.7% triethylamine, 2.2% camphorsulfonic acid and 1.6% m-phenylenediamine for 20 seconds to fully infiltrate the basement membrane with the aqueous phase solution. Subsequently, the solution was poured off. Next, after ensuring that there was no visible liquid on the surface of the membrane, the surface of the membrane was immersed in a n-heptane solution containing 0.08% trimesoyl chloride and 1% dimethyl carbonate to initiate interfacial polymerization. After reacting for 20 s, the membrane was heat-treated at 70°C for 3 min to prepare an aromatic polyamide composite reverse osmosis membrane, which was immediately washed thoroughly with deionized water.

[0044] According to the method of Example 1, filter 2000ppm sodium chloride aqueous solution at 15.5bar and 25°C to test the membrane performance, and the flux and rejection rate of the composite reverse osmosis membran...

Embodiment 3

[0046] The surface of the polysulfone-based membrane was immersed in an aqueous phase solution containing 0.9% triethylamine, 2.4% camphorsulfonic acid and 1.8% m-phenylenediamine for 25 seconds to fully infiltrate the basement membrane with the aqueous phase solution. Subsequently, the solution was poured off. Next, after ensuring that there was no visible liquid on the surface of the membrane, the surface of the membrane was soaked in a n-heptane solution containing 0.1% trimesoyl chloride and 1.2% dimethyl carbonate to initiate interfacial polymerization. After reacting for 25 s, the membrane was heat-treated at 75°C for 4 min to prepare an aromatic polyamide composite reverse osmosis membrane, which was then fully washed with deionized water immediately.

[0047] According to the method of Example 1, filter 2000ppm sodium chloride aqueous solution at 15.5bar and 25°C to test the membrane performance, and the flux and rejection rate of the composite reverse osmosis membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

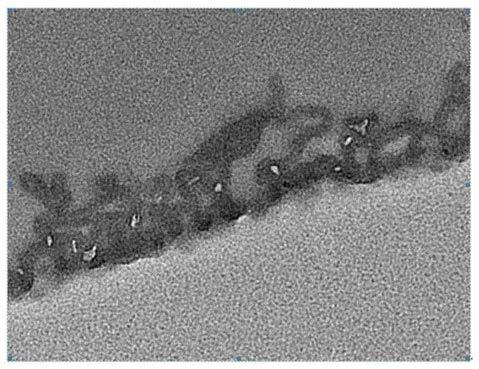

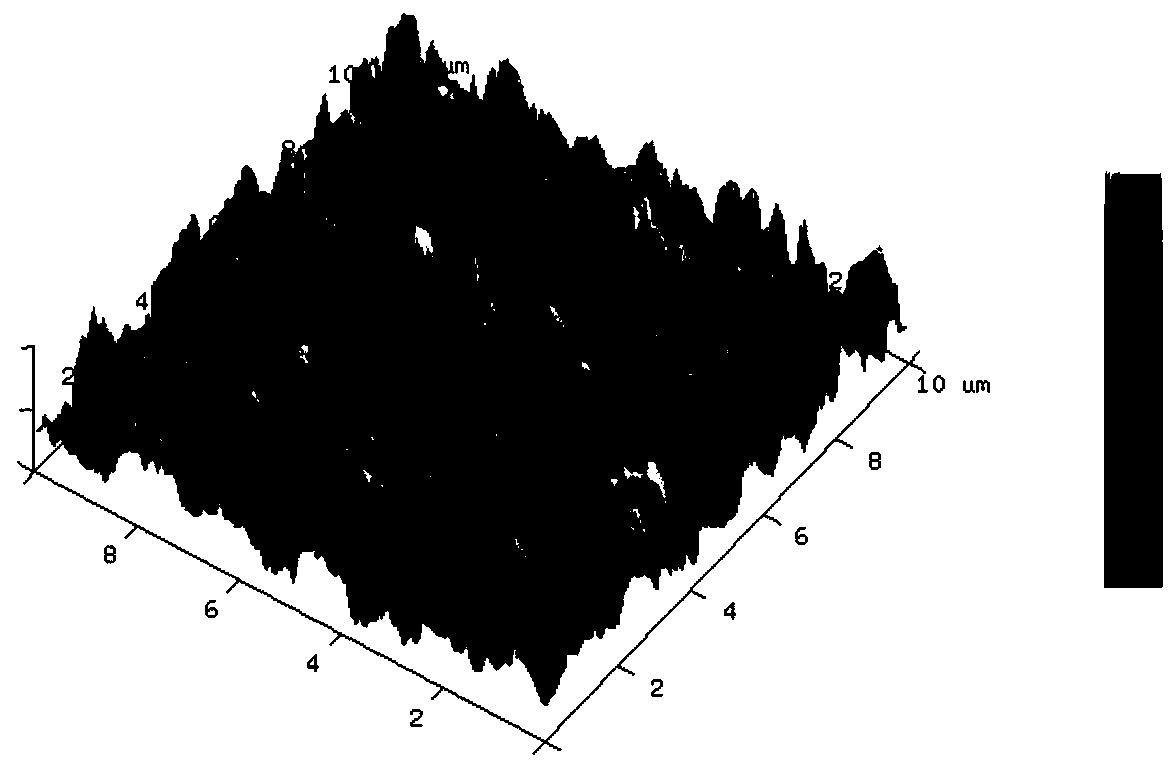

| surface roughness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com