Hydrofining catalyst as well as preparation method and application thereof

A hydrofining and catalyst technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as high hydrodesulfurization activity, and does not involve research on the oxidation and desulfurization performance of multi-stage porous TS-1 molecular sieves , to enhance the oxidation activity, promote the formation of hydroxyl groups, and inhibit the polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

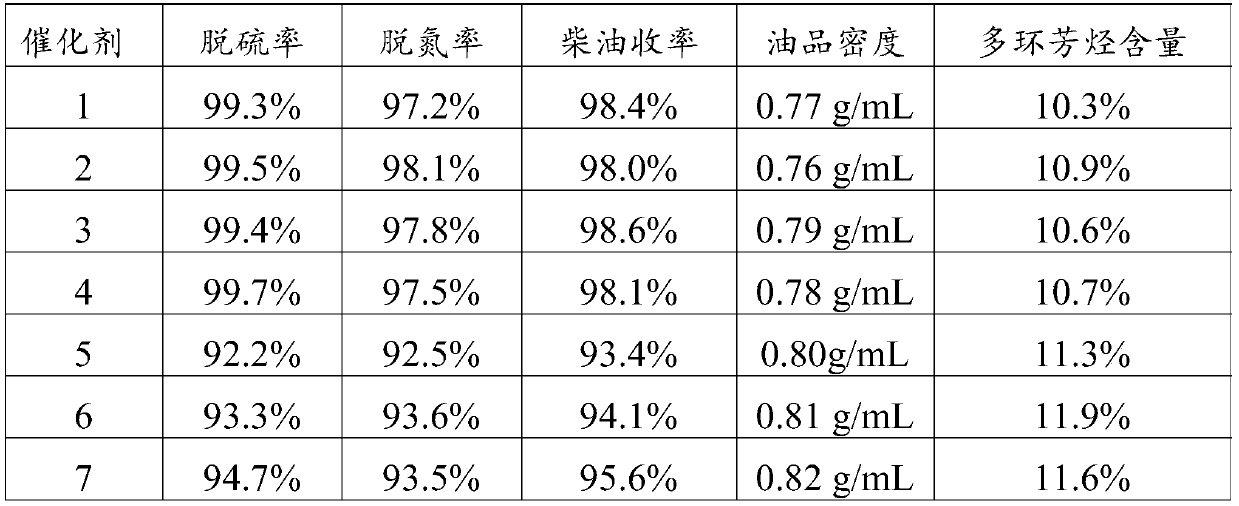

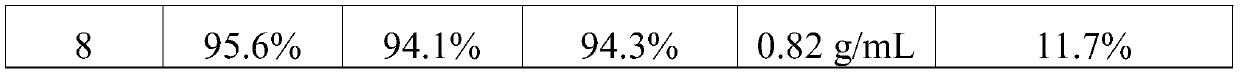

Examples

preparation example Construction

[0027] On the one hand, the invention provides a kind of preparation method of hydrorefining catalyst, and this preparation method comprises the following steps:

[0028] 1) Put the TS-1 zeolite raw powder in an alkaline solution for constant temperature treatment, and then cool, filter, wash, dry and roast to obtain a solid product A;

[0029] 2) ion-exchanging the solid product A with an ammonium nitrate solution to obtain a hierarchically porous TS-1 zeolite molecular sieve;

[0030] 3) Mixing the hierarchically porous TS-1 zeolite molecular sieve with alumina to form a catalyst carrier; wherein, based on the total mass of the catalyst carrier, the mass fraction of the hierarchically porous TS-1 zeolite molecular sieve is 10 %-40%;

[0031] 4) impregnate the hierarchically porous TS-1 zeolite molecular sieve with the solution containing the molybdenum source and the cobalt source by an equal volume impregnation method, after the impregnation is completed, dry and roast to ...

Embodiment 1

[0048] Take 10 g of TS-1 zeolite raw powder and place it in 200 mL of 0.2 mol / L sodium hydroxide aqueous solution, and stir in a constant temperature water bath at 65°C for 4 hours. After the constant temperature treatment was completed, it was rapidly cooled to room temperature, the solid was filtered, washed with deionized water, and dried at 90°C for 3h, and then the dried solid was calcined at 600°C for 12h to obtain a solid product A. The solid product A is ion-exchanged three times with ammonium nitrate solution to obtain a multi-order porous TS-1 zeolite molecular sieve.

[0049] The multi-stage porous TS-1 zeolite molecular sieve is ground with alumina powder to obtain a catalyst carrier, wherein, based on the total mass of the catalyst carrier, the mass ratio of the multi-stage porous TS-1 zeolite molecular sieve is 10%.

[0050] A solution was prepared with ammonium metamolybdate as the molybdenum source and cobalt nitrate hexahydrate as the cobalt source, and the ca...

Embodiment 2

[0054] Take 10 g of TS-1 zeolite raw powder and place it in 200 mL of 0.1 mol / L sodium hydroxide aqueous solution, and stir in a constant temperature water bath at 70°C for 2 h. After the constant temperature treatment was completed, it was rapidly cooled to room temperature, the solid was filtered, washed with deionized water, and dried at 100°C for 2h, and then the dried solid was calcined at 500°C for 12h to obtain a solid product A. The solid product A is ion-exchanged three times with ammonium nitrate solution to obtain a multi-order porous TS-1 zeolite molecular sieve.

[0055] The multi-stage porous TS-1 zeolite molecular sieve is ground with alumina powder to obtain a catalyst carrier, wherein, based on the total mass of the catalyst carrier, the mass ratio of the multi-stage porous TS-1 zeolite molecular sieve is 25%.

[0056] Using ammonium metamolybdate as the molybdenum source and cobalt nitrate hexahydrate as the cobalt source, a solution was prepared, and the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com