Covalent triazine organic framework composite photocatalyst with surface confinement monodisperse Pt nanoparticles as well as preparation method and application of covalent triazine organic framework composite photocatalyst

A technology of covalent triazine and organic framework, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of insufficient catalytic effect of composite photocatalytic systems Unsatisfactory, limited photocatalyst and co-catalyst high charge transfer, surface co-catalyst is easy to aggregate and leaching, etc., to achieve the effect of large-scale promotion, improve charge transfer efficiency, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

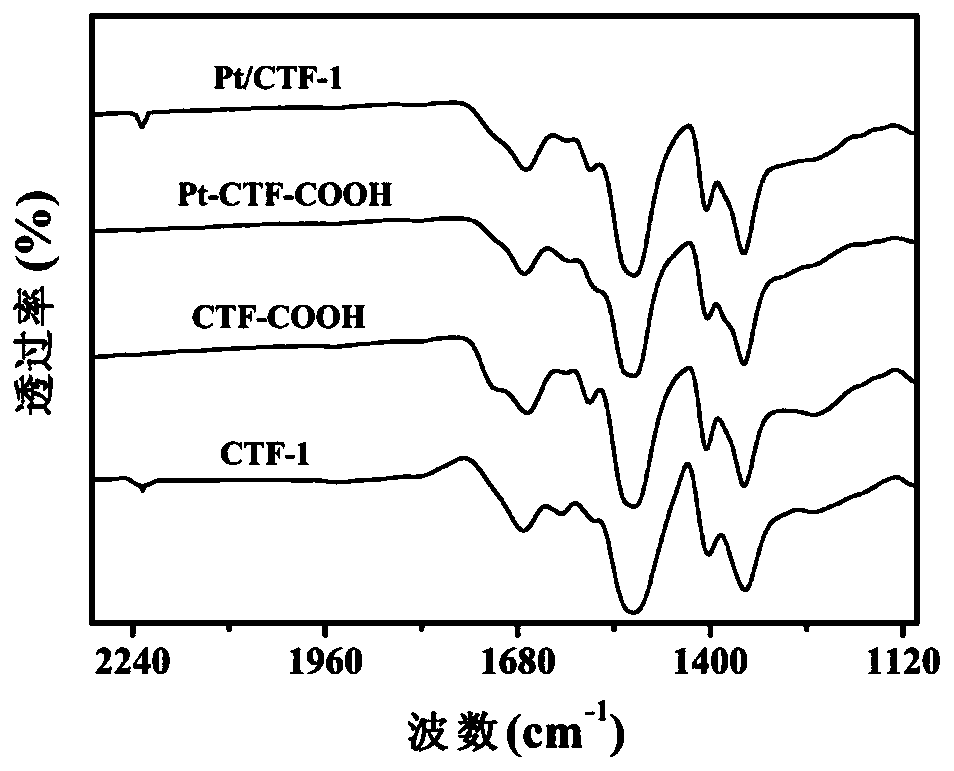

[0027] The preparation of the covalent triazine organic framework, the specific steps are: under the condition of 0 ℃ and stirring, add 12mL trifluoromethanesulfonic acid into 30mL chloroform to form a mixed solution, dissolve 4.26g of terephthalonitrile in 200mL Chloroform solution was added dropwise to the mixed solution under a nitrogen atmosphere, stirred for 2 hours, replaced with an oil bath, heated to 40°C, and continued to stir for 48 hours; stirred for 2 hours with an aqueous ammonia solution of pH=8-9, washed with water until neutral, and freeze-dried ; The freeze-dried samples were mixed with ZnCl 2 Grind evenly at a molar ratio of 1:0.8, calcinate at 400°C and argon for 10 minutes, then wash several times with 0.5 mol / L aqueous hydrochloric acid and deionized water, and freeze-dry to obtain the covalent triazine organic framework , denoted as CTF-1.

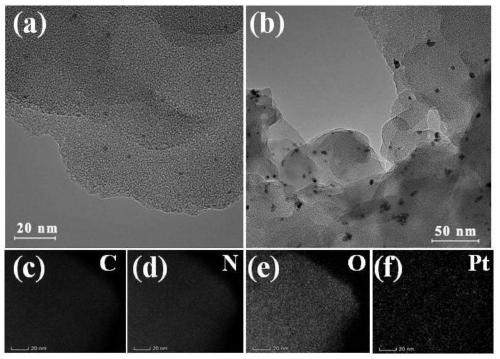

[0028] Preparation of CTF-COOH: Disperse 0.2 g of pre-synthesized covalent triazine organic framework in 50 mL of ...

Embodiment 2

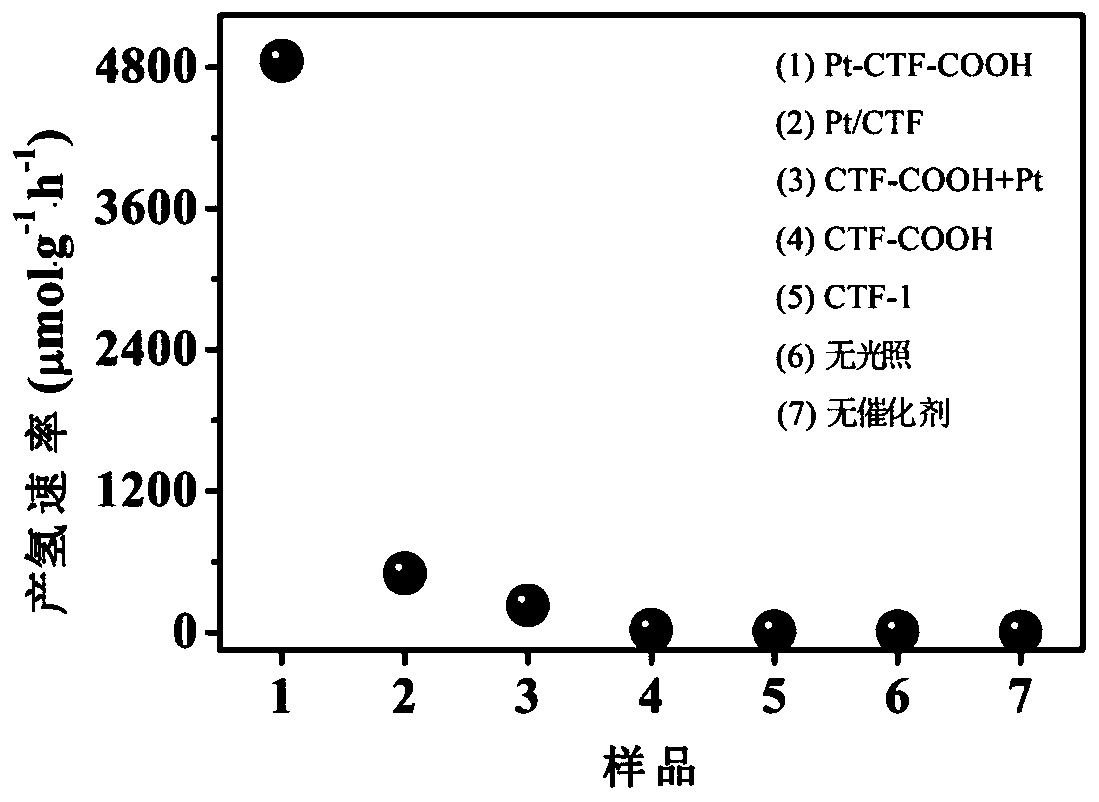

[0033] Performance test of Pt-CTF-COOH catalytic water splitting for hydrogen production under visible light

[0034] The prepared Pt-CTF-COOH is used as a photocatalyst to realize the application of water splitting and hydrogen production under the excitation of visible light. Specifically, 20mg of Pt-CTF-COOH composite photocatalyst is weighed and dispersed in 80mL of an aqueous solution containing 8mL of triethanolamine. Stir evenly, turn on the light source under vacuum conditions to carry out photocatalytic reaction, and the product is detected by gas chromatography. The light source used in the experiment is a 300W xenon lamp, and a filter is used to ensure that the incident light is visible light (420nm image 3 As shown, (1-5) are respectively based on Pt-CTF-COOH, Pt / CTF-1, physical mixture CTF-COOH+Pt, CTF-COOH and CTF-1 as photocatalytic hydrogen production under the condition of visible light (6 and 7) are the hydrogen production rates under the conditions of no lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com