A method for separating and recovering acid and metal ions in iron and steel pickling waste liquid

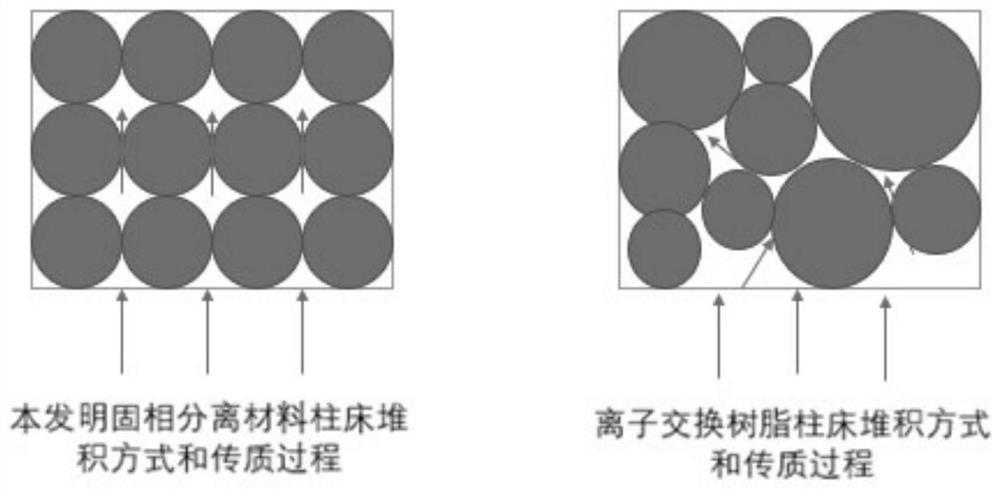

A technology for iron and steel pickling waste liquid and metal ions, which is applied in chemical instruments and methods, metallurgical wastewater treatment, special treatment targets, etc., can solve the problems of high treatment cost and high equipment demand, and achieve high separation efficiency, fast separation efficiency, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

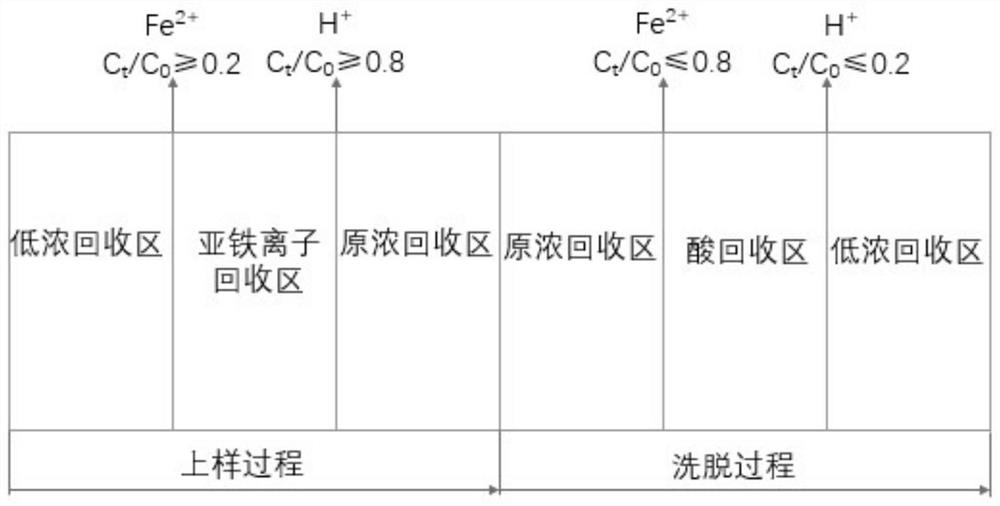

Method used

Image

Examples

Embodiment 1

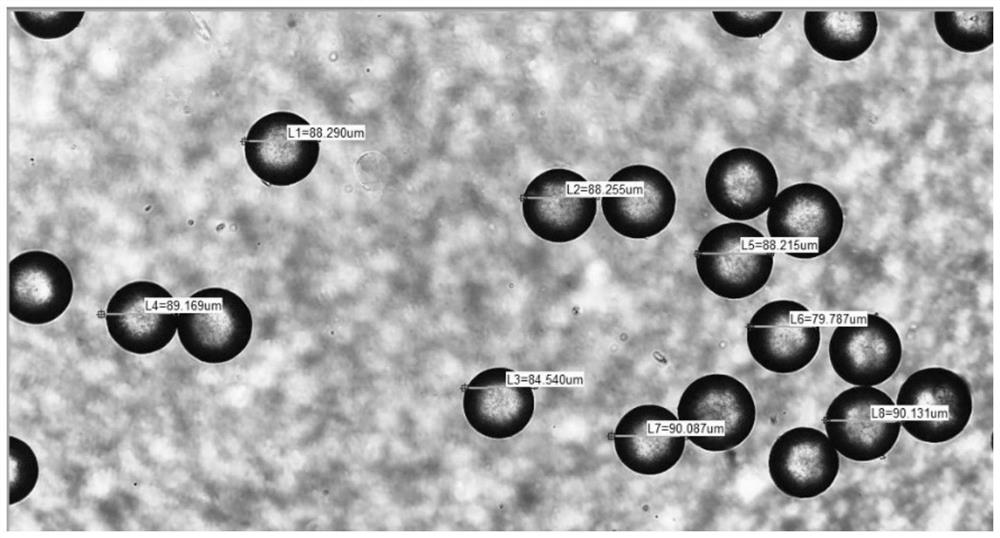

[0076] (1) Preparation of chromatographic separation column: take 300mL of solid phase separation material and disperse it in 500mL of water, ultrasonically shake for 15min, the microscopic examination picture is as follows image 3 shown. The dispersed solid phase separation material is wet-packed. Put 300mL of solid phase separation material in the cartridge (DAC dynamic column DAC50), and fill up the remaining part with water to ensure that there are no air bubbles. The packing pressure is 2.5MPa. After the column is packed, wash it with 3BV pure water until there is no turbidity (holding pressure 2.5Mpa: the polymer ball has a 10% expansion rate).

[0077] Wherein, the solid phase separation material is quaternary amine (-N + (CH 3 ) 3 ) modified styrene-divinylbenzene copolymer particles (quaternary ammonium structure content of 15.12%). Particle size 85 microns, particle size difference ± 10 microns; specific surface area 800m 2 / g, pore diameter 50A, pore volume ...

Embodiment 2

[0083] (1) Preparation of chromatographic separation column: Disperse 300 mL of solid-phase separation material in 500 mL of water, and oscillate ultrasonically for 15 min. The dispersed solid phase separation material is wet-packed. Put 300mL of solid phase separation material in the cartridge (DAC dynamic column DAC50), and fill up the remaining part with water to ensure that there are no air bubbles. The packing pressure is 2.5MPa. After the column is packed, wash it with 3BV pure water until there is no turbidity (holding pressure 2.5Mpa: the polymer ball has a 10% expansion rate). Wherein, the solid phase separation material is styrene-divinylbenzene copolymer particles modified by quaternary ammonium (the content of quaternary ammonium structure is 12.76%). Particle size 35 microns, particle size difference +10 microns; specific surface area 800m 2 / g, pore diameter 50A, pore volume 1.2cm 3 / g.

[0084] (2) Loading the sample, take the iron and steel pickling waste ...

Embodiment 3

[0089](1) Preparation of chromatographic separation column: Disperse 300 mL of solid-phase separation material in 500 mL of water, and oscillate ultrasonically for 15 min. The dispersed solid phase separation material is wet-packed. Put 300mL of solid phase separation material in the cartridge (DAC dynamic column DAC50), and fill up the remaining part with water to ensure that there are no air bubbles. The packing pressure is 2.5MPa. After the column is packed, wash it with 3BV pure water until there is no turbidity (holding pressure 2.5Mpa: the polymer ball has a 10% expansion rate). The solid phase separation material is styrene-divinylbenzene copolymer particles modified by quaternary ammonium (the content of quaternary ammonium structure is 13.45%). Particle size 50 microns, particle size difference ± 10 microns; specific surface area 800m 2 / g, pore diameter 50A, pore volume 1.2cm 3 / g.

[0090] (2) Loading the sample, take the iron and steel pickling waste liquid (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com