Method for efficiently separating and purifying sugar and acid in bio-based material hydrolysate

A technology for separation, purification and hydrolysis, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of affecting the life of separation materials, poor separation effect, equipment complexity, etc., and achieve low equipment requirements. , the effect of fast mass transfer rate and low waste liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

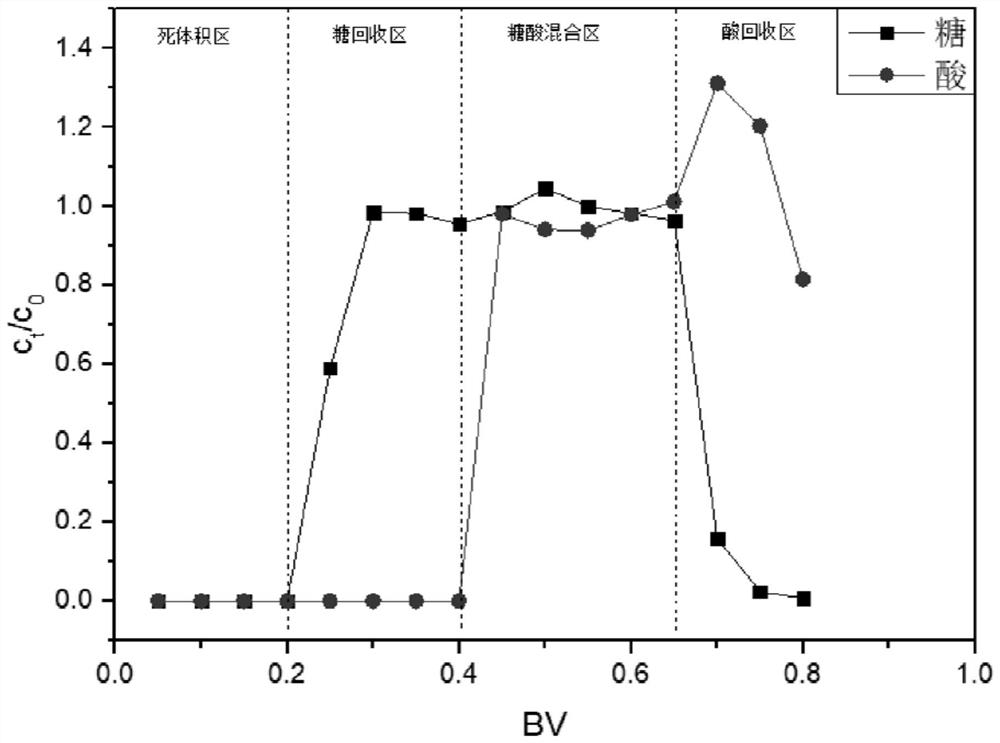

[0041] (1) Sample loading: The bio-based material hydrolyzate (sugar-acid mixture) is loaded into the reciprocating flow low bed containing the amphoteric solid phase separation material. The effluent is recovered in two stages, namely the dead volume area and the sugar recovery area.

[0042] Wherein, the sugar-acid mixture is 5% glucose-20% sulfuric acid-2% acetic acid. The amphoteric solid phase separation material: specific surface area: 1600m 2 / g, the particle size is 85 μm, and the distribution difference of the particle size is ±10 μm. The terminal of the amphoteric solid phase separation material is a penetrating amphoteric group of quaternary ammonium and carboxylic acid, the exchange amount of basic group: 2.8mmol / g, and the exchange amount of acid group: 2.4mmol / g. The reciprocating flow low bed is a column bed with a ratio of height to diameter of 1.5:1. The sample loading flow rate is 6BV / h.

[0043] (2) Elution: elution with pure water from the other end of ...

Embodiment 2

[0048] (1) Sample loading: The bio-based material hydrolyzate (sugar-acid mixture) is loaded into the reciprocating flow low bed containing the amphoteric solid phase separation material. The effluent is recovered in two stages, namely the dead volume area and the sugar recovery area.

[0049] Among them, the sugar-acid mixture is 5% glucose, 2% fructose-8% hydrochloric acid-2% acetic acid. The amphoteric solid phase separation material: specific surface area: 1600m 2 / g, the particle size is 40 μm, and the distribution difference of the particle size is ±10 μm. The end of the solid phase separation material is a penetrating amphoteric group of quaternary ammonium and carboxylic acid, the exchange capacity of basic groups: 3.8mmol / g, and the exchange capacity of acidic groups: 2.6mmol / g. The reciprocating low bed is a column bed with a ratio of height to diameter of 1.5:1. The sample loading flow rate is 1BV / h.

[0050] (2) Elution: elution with pure water from the other e...

Embodiment 3

[0055] (1) Sample loading: The bio-based material hydrolyzate (sugar-acid mixture) is loaded into the reciprocating flow low bed containing the amphoteric solid phase separation material. The effluent is recovered in two stages, namely the dead volume area and the sugar recovery area.

[0056] Wherein, the sugar-acid mixed solution is 5% glucose-10% sulfuric acid-1% acetic acid. The amphoteric solid phase separation material: specific surface area: 1600m 2 / g, the particle size is 100 μm, and the distribution difference of the particle size is ±10 μm. The terminal of the solid phase separation material is a penetrating amphoteric group of quaternary ammonium and carboxylic acid, the exchange capacity of the basic group: 2.5mmol / g, and the exchange capacity of the acid group: 2.1mmol / g. The reciprocating low bed is a column bed with a ratio of height to diameter of 1.5:1. The sample loading flow rate is 10BV / h.

[0057] (2) Elution: elution with pure water from the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com