Light-weight high-strength straw board for interior wall and preparation method and application of light-weight high-strength straw board

A straw board, lightweight technology, applied in the coating and other directions, can solve the problems of poor mechanical properties, poor adhesion, poor thermal insulation, etc., and achieve the effects of low cost, light weight and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

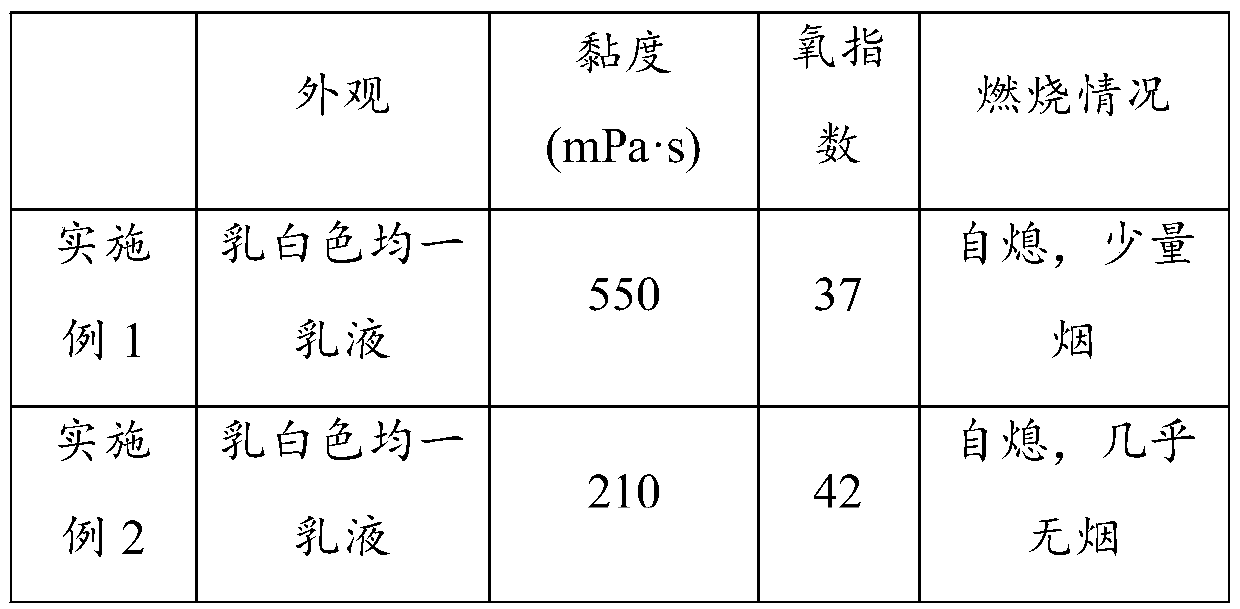

Embodiment 1

[0023] A lightweight high-strength straw board for interior walls, the lightweight high-strength straw board for interior walls is composed of a cement mortar layer, a straw board core and a coating, the cement mortar layer is made of sulphoaluminate cement, and the straw board The raw materials of the core are proportioned in parts by mass: 40-80 parts of straw, 1-2 parts of filler, 4-6 parts of metal oxide, and 5-15 parts of halogen-free flame-retardant adhesive; the raw materials of the coating are according to The ratio of parts by mass is: 100 parts of acrylate, 4-8 parts of ammonium dihydrogen phosphate, 6-10 parts of modified kaolin, 6-10 parts of sodium dihydrogen phosphate, 0.5-5 parts of potassium tetraborate, vinyl triethyl 0.05-0.5 parts of oxysilane, 0.6-1 parts of N-methyl methacrylate, 1-2 parts of graphene, 5-9 parts of triphenyl phosphate, 1-3 parts of calcium lignosulfonate, in dispersant Disperse evenly.

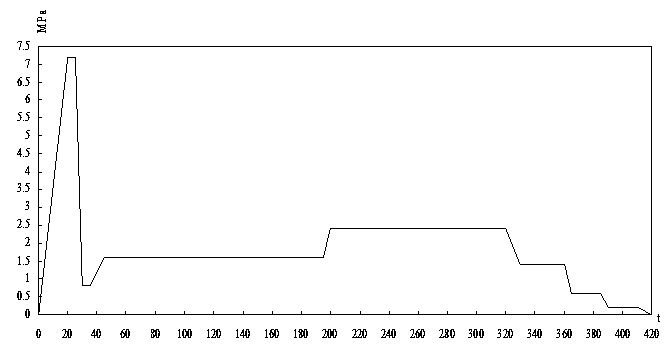

[0024] The preparation method of the lightweight hi...

Embodiment 2

[0035] A lightweight high-strength straw board for interior walls, the lightweight high-strength straw board for interior walls is composed of a cement mortar layer, a straw board core and a coating, the cement mortar layer is made of sulphoaluminate cement, and the straw board The raw materials of the core are proportioned in parts by mass: 40-80 parts of straw, 1-2 parts of filler, 4-6 parts of metal oxide, and 5-15 parts of halogen-free flame-retardant adhesive; the raw materials of the coating are according to The ratio of parts by mass is: 100 parts of acrylate, 4-8 parts of ammonium dihydrogen phosphate, 6-10 parts of modified kaolin, 6-10 parts of sodium dihydrogen phosphate, 0.5-5 parts of potassium tetraborate, vinyl triethyl 0.05-0.5 parts of oxysilane, 0.6-1 parts of N-methyl methacrylate, 1-2 parts of graphene, 5-9 parts of triphenyl phosphate, 1-3 parts of calcium lignosulfonate, in dispersant Disperse evenly.

[0036] The preparation method of the lightweight hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com