Stainless steel ball valve surface abrasion resisting and corrosion resisting high-phosphorus plating solution and abrasion resisting and corrosion resisting preparing method

A stainless steel ball, corrosion-resistant technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as stability problems, improve wear resistance, improve corrosion resistance, and good lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A stainless steel ball valve surface wear-resistant and corrosion-resistant high phosphorus Ni-P-SiO 2 The preparation of composite coating is carried out according to the following steps:

[0023] (1) Equipped with nano-SiO 2 The acidic Ni-P plating solution, its plating solution composition is NiSO 4 ·7H 2 O 25g / L, NaH 2 PO 2 ·H 2 O 20g / L, CDTA (1,2-cyclohexanediaminetetraacetic acid) 35g / L, lactic acid 8ml / L, Ce 2 (SO 4 ) 3 ·8H 2 O is 3mg / L, sodium lauryl sulfate is 0.5g / L, SiO with a size of 60nm 2 10g / L, PDDA (diethylene glycol diacrylate) 3ml / L, with NaOH or H 2 SO 4 Adjust the pH of the solution to 4.

[0024] (2) will contain nano-SiO 2 The acidic Ni-P plating solution was stirred ultrasonically for 10 min, and then placed in a magnetic stirrer for 20 min.

[0025] (3) Using austenitic stainless steel (3cm×5cm) samples, first put the samples into 40g / L NaOH, 25g / L NaOH 2 CO 3 , 7g / L Na 3 PO 4 , 10g / L Na 2 SiO 3 and 1.5g / L OP-10 in the water-b...

Embodiment 2

[0029] The plating solution prepared in Step 2 of Example 1 was placed in an air environment for 30 days. Then according to Example 1 step 3-4 to obtain coated with Ni-P-SiO 2 Composite coated stainless steel samples.

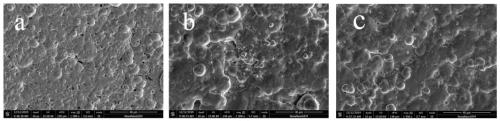

[0030] After washing and drying the obtained samples, the surface morphology was observed by SEM ( figure 1 c), coating surface Ni-P content DES analysis (table 1), friction coefficient and wear rate analysis (table 2),

Embodiment 3

[0045] A stainless steel ball valve surface wear-resistant and corrosion-resistant high phosphorus Ni-P-SiO 2 The preparation of composite coating is carried out according to the following steps:

[0046] (1) Equipped with nano-SiO 2 The acidic Ni-P plating solution, its plating solution composition is NiSO 4 ·7H 2 O 25g / L, NaH 2 PO 2 ·H 2 O 20g / L, CDTA (1,2-cyclohexanediaminetetraacetic acid) 35g / L, lactic acid 5ml / L, Ce2(SO4)3·8H2O 2mg / L, sodium lauryl sulfate 0.5g / L , PDDA (diethylene glycol diacrylate) 3ml / L, nano-SiO with a size of 60nm 2 10g / L, with NaOH or H 2 SO 4 Adjust the pH of the solution to 4.

[0047] (2) will contain nano-SiO 2 The acidic Ni-P plating solution was stirred ultrasonically for 10 min, and then placed in a magnetic stirrer for 20 min.

[0048] (3) Using austenitic stainless steel (3cm×5cm) samples, first put the samples into 40g / L NaOH, 25g / L NaOH 2 CO 3 , 7g / L Na 3 PO 4 , 10g / L Na 2 SiO 3 and 1.5g / L OP-10 in the water-based compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com