Preparation method of cobalt molybdate/nickel cobaltate composite material with three-dimensional flower-ball-shaped structure

A spherical structure and composite material technology, applied in the field of composite materials and energy storage applications, can solve the problems of low capacitance value, pseudo-capacitor instability, etc., and achieve improved energy storage performance, excellent electrochemical performance, improved electrochemical performance and the effect of its stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

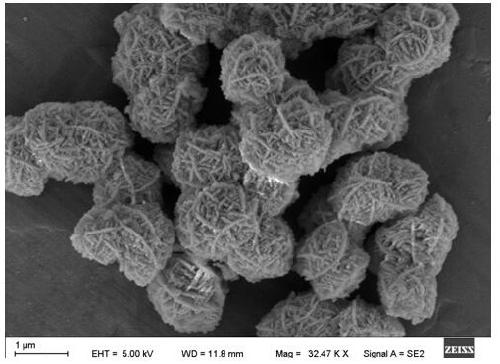

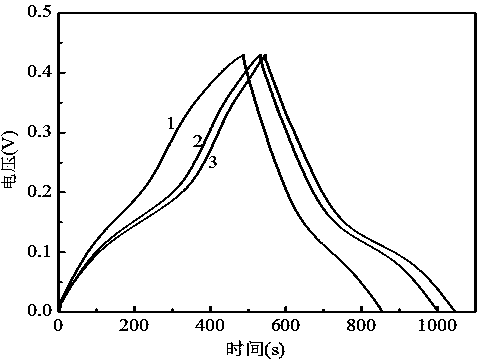

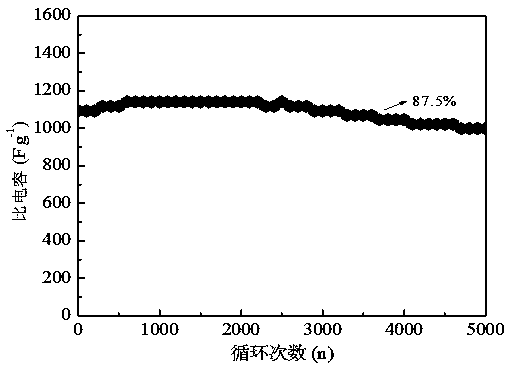

Embodiment 1

[0019] 1mmoL cobalt nitrate, 0.33mmoL nickel nitrate and 0.33mmoL sodium molybdate were added to 20mL deionized water respectively, and after stirring and dissolving, they were uniformly mixed to obtain a clear solution, and then the obtained clear solution was transferred to a hydrothermal reaction kettle, and heated at 180 After hydrothermal reaction at ℃ for 12 h, naturally cooled to room temperature, the product was taken out, washed with water and ethanol by centrifugation, and then dried at 60 °C for 12 h to obtain CoMoO 4 / NiCo 2 o 4 precursor. Then put the obtained precursor material into a tube furnace for calcination, and anneal at 350 °C for 2 h at a heating rate of 2 °C / min in an Ar atmosphere to obtain CoMoO 4 with NiCo 2 o 4 CoMoO with a theoretical molar ratio of 1:1 and a three-dimensional flower spherical structure 4 / NiCo 2 o 4 Composite materials, their structure and properties see figure 1 , 2 , 3.

Embodiment 2

[0021]1mmoL cobalt nitrate, 0.4mmoL nickel nitrate and 0.2mmoL sodium molybdate were added to 20mL deionized water respectively, stirred and dissolved, and mixed evenly to obtain a clear solution, then the obtained clear solution was transferred to a hydrothermal reaction kettle, and heated at 180 After hydrothermal reaction at ℃ for 12.5 h, the product was naturally cooled to room temperature, and the product was taken out, washed with water and ethanol, and dried at 60 °C for 12 h to obtain the cobalt molybdate precursor. Then put the obtained precursor material into a tube furnace for calcination, and anneal at 355 °C for 2 h at a heating rate of 2 °C / min in an Ar atmosphere to obtain CoMoO 4 with NiCo 2 o 4 CoMoO with a theoretical molar ratio of 1:2 4 / NiCo 2 o 4 Composite materials, their structure and properties see figure 1 , 2 .

Embodiment 3

[0023] Add 1mmoL cobalt nitrate, 0.25mmoL nickel nitrate and 0.5mmoL sodium molybdate into 20mL deionized water respectively, stir and dissolve them and mix them uniformly to obtain a clear solution, then transfer the obtained clear solution to a hydrothermal reaction kettle, and set the temperature at 185 After hydrothermal reaction at ℃ for 12 h, the product was naturally cooled to room temperature, and the product was taken out, washed with water and ethanol by centrifugation, and then dried at 60 °C for 12 h to obtain the cobalt molybdate precursor. Then the obtained precursor material was put into a tube furnace for calcination, and annealed at 350 °C for 2.5 h at a heating rate of 1 °C / min in an Ar atmosphere to obtain CoMoO 4 with NiCo 2 o 4 Three-dimensional flower-like spherical structure CoMoO with a theoretical molar ratio of 2:1 4 / NiCo 2 o 4 Composite materials, their structure and properties see figure 1 , 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com