Iron carbide composite titanium monoxide nanoparticle photo-thermal catalyst and preparation thereof

A technology of titanium monoxide and nanoparticles, applied in the field of photocatalytic materials, can solve the problems of poor photocatalytic carbon dioxide reduction performance, easy recombination of photogenerated carriers, and few surface active sites, achieving low carrier recombination rate, High cycle stability, improving the effect of the catalytic process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

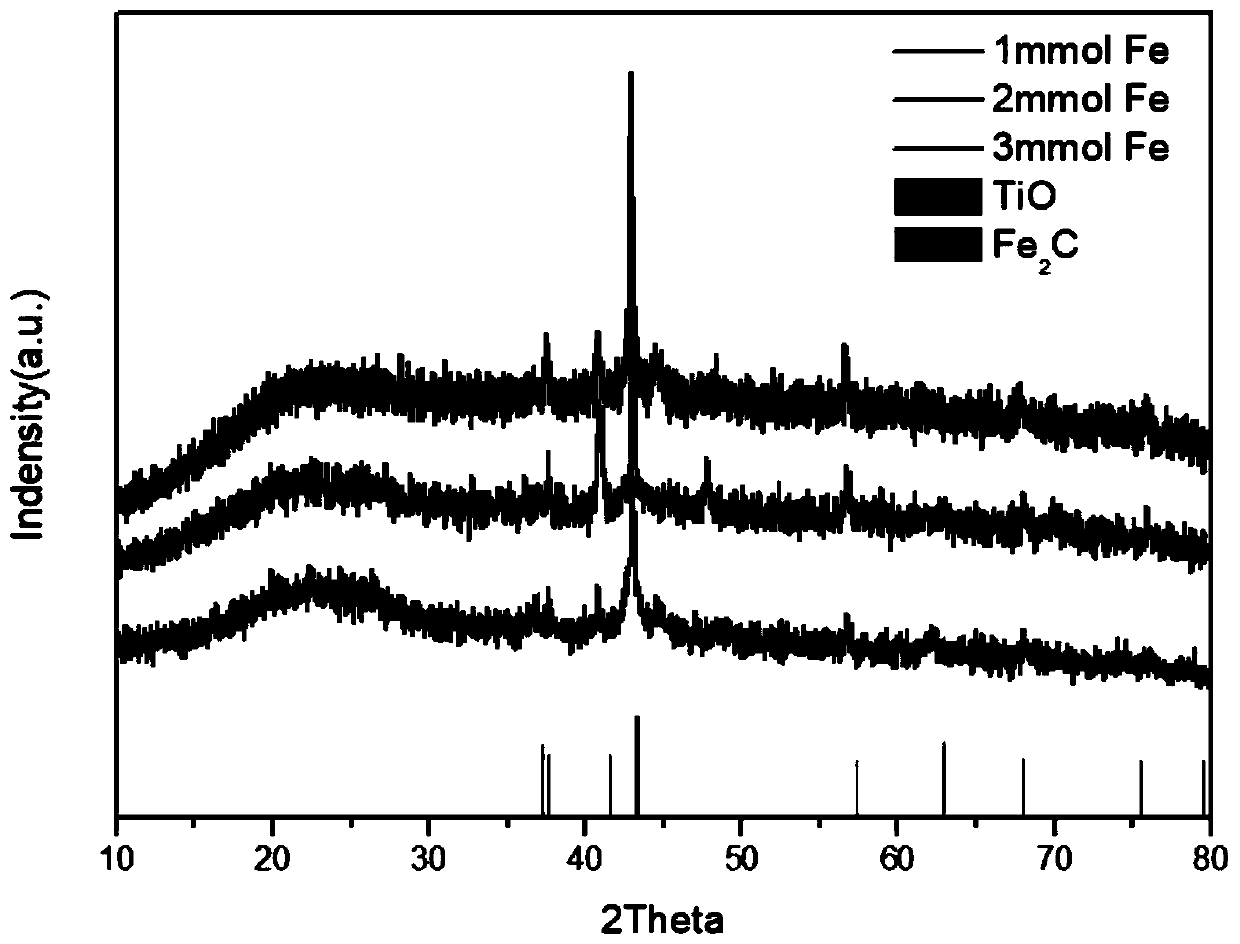

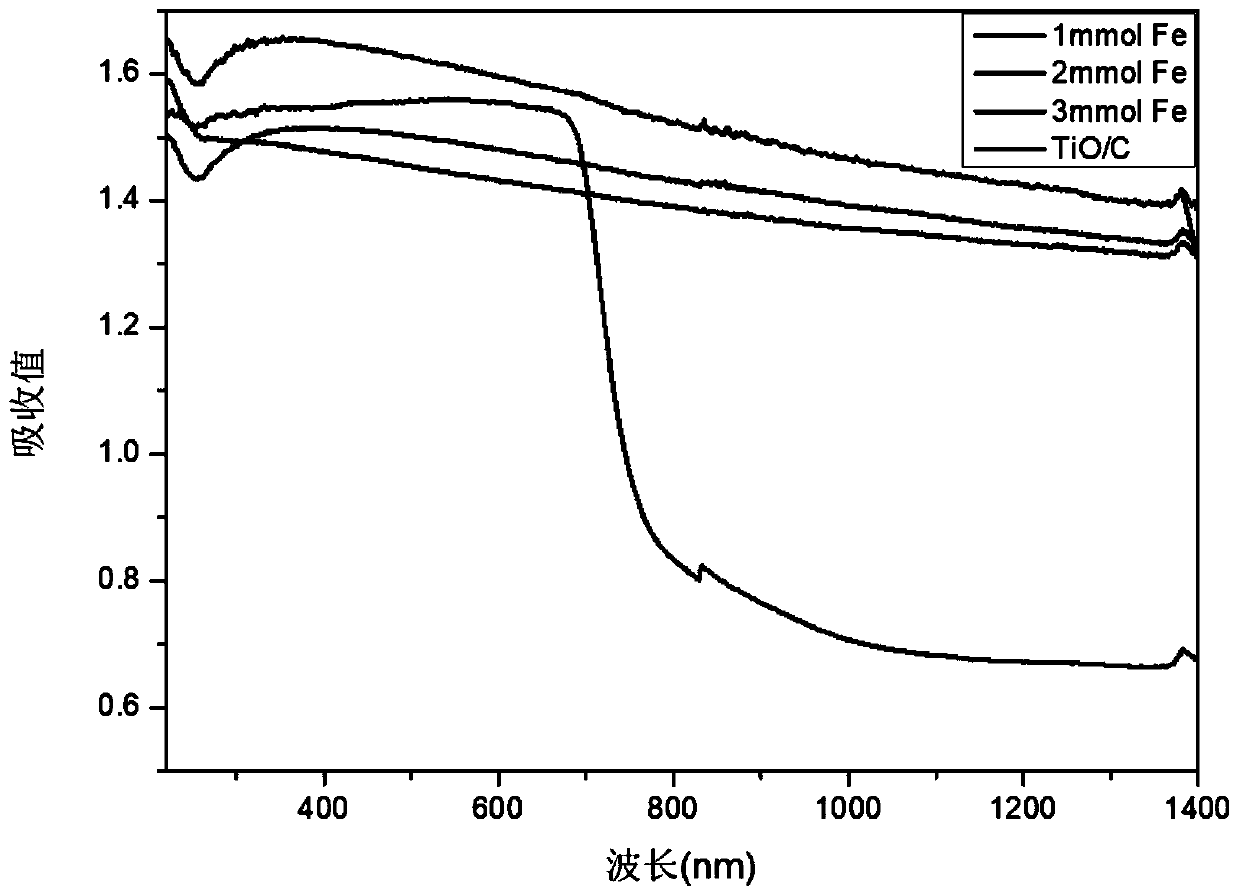

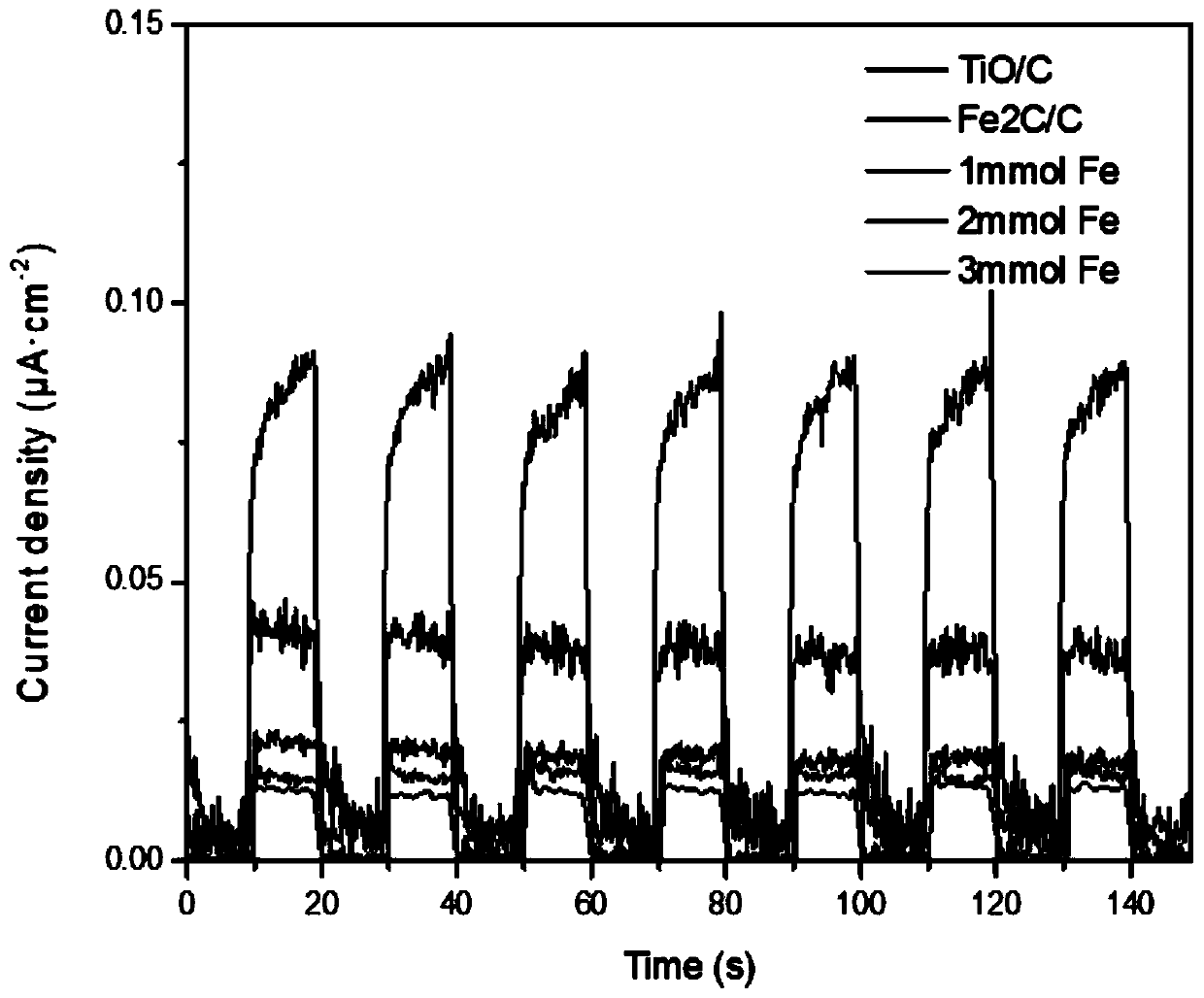

[0051] A nanoparticle photocatalyst composed of iron carbide and titanium monoxide mainly contains four main elements of Fe, C, Ti and O, and is prepared by a method comprising the following steps:

[0052] (1) Fe 2 Preparation of C / C / TiO precursor

[0053] Dissolve 0.8g of PAN in 10mL of DMF solution, heat it in an oil bath at 60°C overnight, then add xmmol of ferric nitrate nonahydrate (x=1, 2, 3), and then add 0.04 g of P25, dried at 60°C after stirring for 24 hours.

[0054] (2) Fe 2 Preparation of C / C / TiO

[0055] Put the dried sample into the crucible and then in NH 3 Under the atmosphere, the heating rate is controlled at 2°C / min, and the temperature is raised to 800°C for calcination for 4 hours to obtain Fe 2 The C / C / TiO bulk product was ground into powder in a mortar to obtain Fe 2 C / C / TiO powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com