Sulfur defect-rich sulfurized ferrophosphorus nanosheet as well as preparation method and application thereof

A technology for ferric phosphorus sulfide and nanosheets, which is applied in the preparation/separation of ammonia, chemical instruments and methods, phosphorus compounds of phosphorus sulfur/selenium/tellurium, etc., can solve the problems of low yield, complicated preparation process, etc. High performance, good reproducibility and considerable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

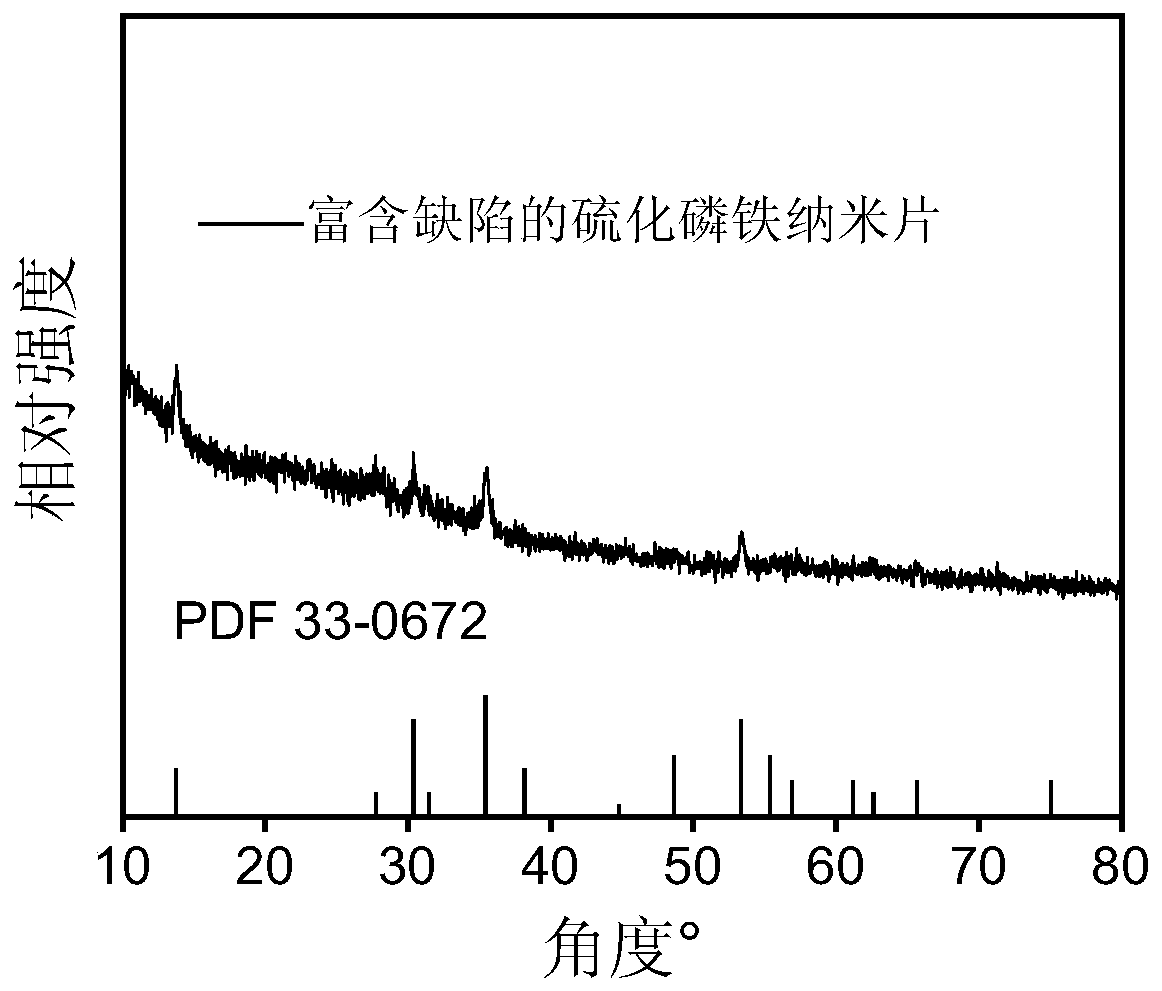

[0039] 1. Preparation of bulk ferrophosphorus sulfide

[0040] (1) Mix iron powder, phosphorus powder and sulfur powder according to the molar ratio of 1:1:3. After fully mixing and grinding, seal the mixed powder in a vacuum quartz glass tube;

[0041] (2) Heat the above-mentioned quartz glass tube with sealed mixed powder in a tube furnace at a temperature of 650°C for 120 hours at a heating rate of 5°C / min, and cool it down to room temperature naturally after heating to obtain massive phosphorous sulfide iron crystals.

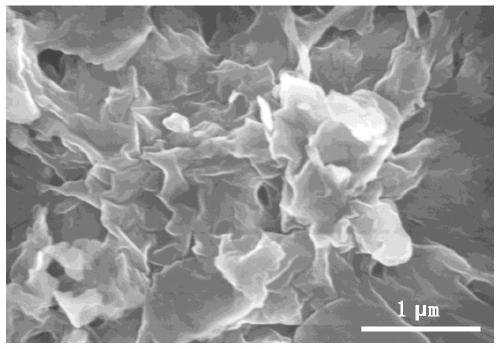

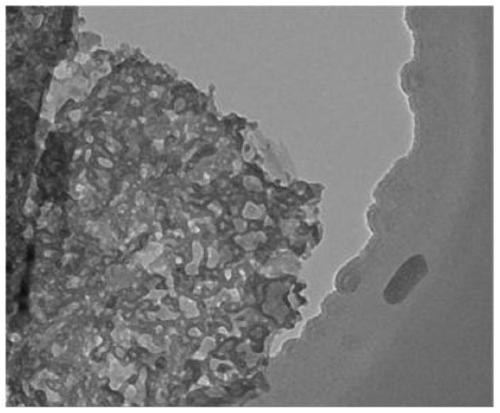

[0042] 2. Electrochemical stripping

[0043] Fix the massive iron phosphorus sulfide on the copper sheet as the working electrode, use platinum wire as the counter electrode, and use N-methylpyrrolidone solution containing 5 mg / mL tetrabutylammonium bromide as the electrolyte to make the massive phosphorus sulfide Immerse the iron and platinum sheets into the electrolyte; continuously apply a negative voltage of -6V to the working electrode for 10 hours t...

Embodiment 2

[0061] 1. Preparation of bulk ferrophosphorus sulfide

[0062] (1) Mix iron powder, phosphorus powder and sulfur powder according to the molar ratio of 1:1:3. After fully mixing and grinding, seal the mixed powder in a vacuum quartz glass tube;

[0063] (2) Heat the above-mentioned quartz glass tube with sealed mixed powder in a tube furnace at a temperature of 650°C for 120 hours at a heating rate of 5°C / min, and cool it down to room temperature naturally after heating to obtain massive phosphorous sulfide iron crystals.

[0064] 2. Electrochemical stripping

[0065] Fix the massive iron phosphorus sulfide on the copper sheet as the working electrode, use platinum wire as the counter electrode, and use N-methylpyrrolidone solution containing 5 mg / mL tetrabutylammonium bromide as the electrolyte to make the massive phosphorus sulfide Immerse the iron and platinum sheets into the electrolyte; continuously apply a negative voltage of -4V to the working electrode for 10 hours t...

Embodiment 3

[0081] 1. Preparation of bulk ferrophosphorus sulfide

[0082] (1) Mix iron powder, phosphorus powder and sulfur powder according to the molar ratio of 1:1:3. After fully mixing and grinding, seal the mixed powder in a vacuum quartz glass tube;

[0083] (2) Heat the above-mentioned quartz glass tube with sealed mixed powder in a tube furnace at a temperature of 650°C for 120 hours at a heating rate of 5°C / min, and cool it down to room temperature naturally after heating to obtain massive phosphorous sulfide iron crystals.

[0084] 2. Electrochemical stripping

[0085] Fix the massive iron phosphorus sulfide on the copper sheet as the working electrode, use platinum wire as the counter electrode, and use N-methylpyrrolidone solution containing 5 mg / mL tetrabutylammonium bromide as the electrolyte to make the massive phosphorus sulfide Immerse the iron and platinum sheets into the electrolyte; continuously apply a negative voltage of -8V to the working electrode for 10 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com