A kind of method that utilizes mud-water mixed solution to prepare microbial flocculant

A technology of microbial flocculant and mud-water mixture, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low yield and low effective content of flocculant, and achieve Improve the yield, use a large amount of enzyme preparation, and prolong the effect of enzyme action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

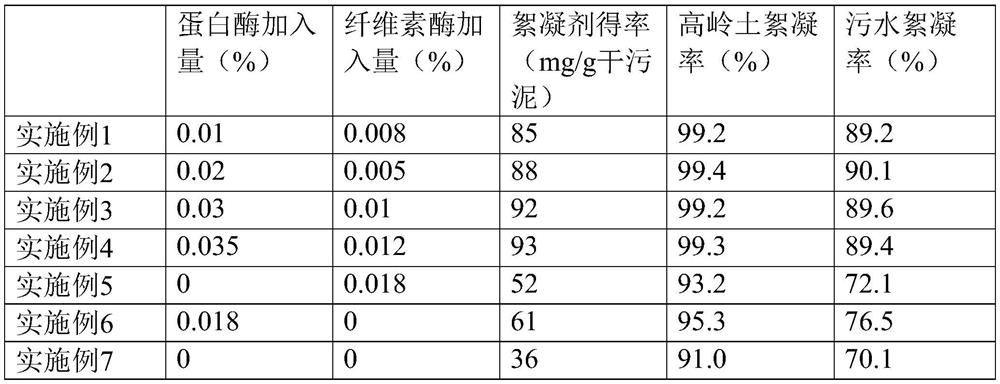

Embodiment 1-7

[0039] A method for preparing a microbial flocculant utilizing a mud-water mixed solution, comprising the following steps:

[0040](1) Take the mud-water mixture at the end of the aeration tank of the sewage treatment plant, the sludge concentration in the mud-water mixture is 3g / L, then add protease and cellulase, and the enzyme activity of the protease is 300,000 U / g, The enzymatic activity of the cellulase is 100,000 U / g, the addition amount of the protease is 0.01-0.03%, the addition amount of the lipase is 0.005-0.01%, and the reaction is carried out at 37°C for 2 hours; The amount of cellulase added is based on the weight of the sludge in the mud-water mixture,

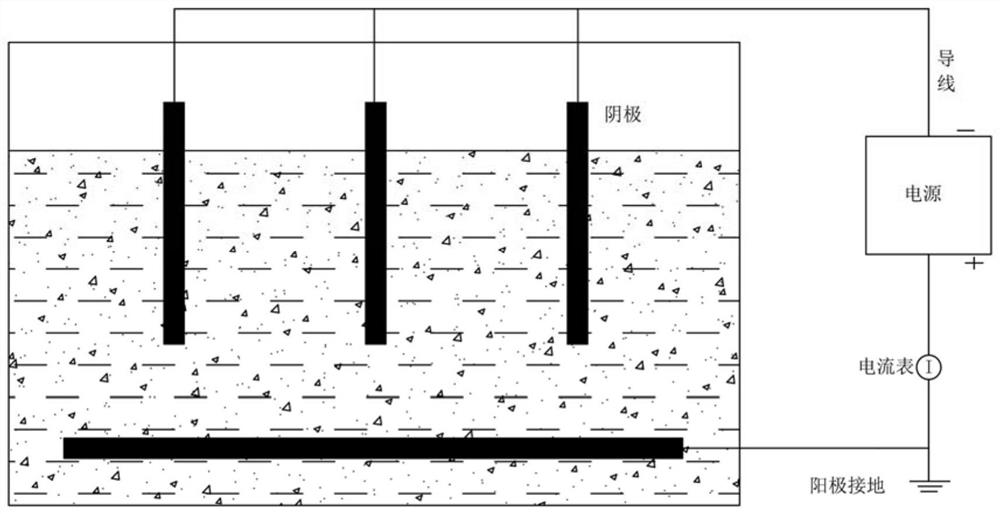

[0041] (2) carry out high-voltage electrostatic precipitation to the suspension, collect the precipitate, and set aside for use. The high-voltage electrostatic precipitation process in the step (2) is as follows: at a voltage of 35KV, electrostatically treating for 20min, and finally standing for 3h, removing th...

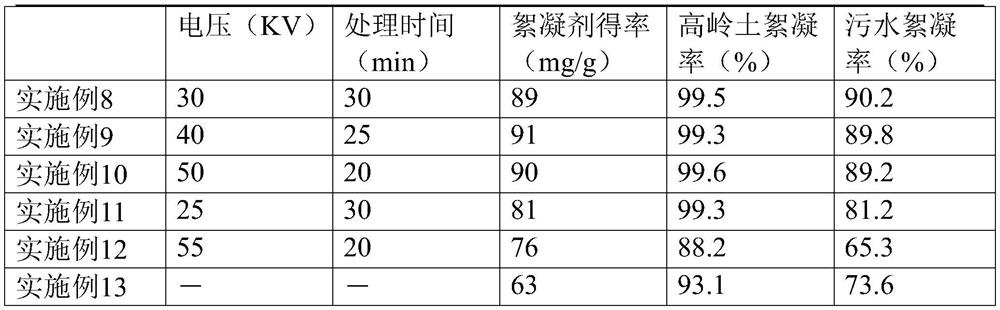

Embodiment 8-13

[0048] A method for preparing a microbial flocculant utilizing a mud-water mixed solution, comprising the following steps:

[0049] (1) Take the mud-water mixture at the end of the aeration tank of the sewage treatment plant, the sludge concentration in the mud-water mixture is 4g / L, then add protease and cellulase, and the enzyme activity of the protease is 300,000 U / g, The enzymatic activity of the cellulase is 100,000 U / g, the addition amount of the protease is 0.02%, the addition amount of the lipase is 0.005%, and the reaction is carried out at 30°C for 3 hours; The amount added is based on the weight of the sludge in the mud-water mixture,

[0050] (2) carry out high-voltage electrostatic precipitation to the suspension, collect the precipitate, and set aside for use. The high-voltage electrostatic precipitation process in the step (2) is: at a voltage of 30-50KV, electrostatically treating for 20-30min, and finally standing for 2h, Remove the supernatant and collect th...

Embodiment 13

[0053] In Example 13, instead of using high-voltage electrostatic precipitation, the method of natural gravity sedimentation was adopted, and the sediment was naturally settled for 12 hours, and then the sludge was collected.

[0054] The high-voltage electrostatic parameters and flocculation effects added with Examples 8-16 are shown in the following table.

[0055]

[0056] It can be seen from the above table that the high-voltage electrostatic parameters have an important influence on the prepared flocculant. If the voltage is too low or too high, the precipitation of proteins, polysaccharides, cellulose and other substances in the mud-water mixture will be incomplete or decomposed and deformed, causing it to flocculate. In particular, the high voltage has more serious damage to the components in the mud-water mixture, so that the flocculation ability of kaolin and sewage is lower than the flocculation effect without high-voltage electrostatic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com