Extraction process of tea saponin in camellia seed meal, and application of tea saponin in amino acid facial soap

An extraction process and tea saponin technology, which are applied in the directions of non-ionic surface active compounds, surface active detergent compositions, sugar derivatives preparation, etc., can solve the problems of low content, reduced purity, high viscosity of tea saponin, etc., Achieve the effect of improving product yield and purity, improving product quality, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The tea saponin extraction process in the camellia dregs of embodiment 1

[0026] Main reagents and raw materials in this embodiment: camellia seed; n-hexane (AR grade); ethanol (AR grade); methanol (AR grade); water (AR grade); dimethyl carbonate (AR grade).

[0027] The tea saponin extraction process in the camellia dregs of the present embodiment comprises the following steps:

[0028] S1. Pretreatment of camellia seeds: wash the camellia seeds, put them in a container, control the time, and crush them into fine particles;

[0029] S2. Degreasing: Weigh 50 g of dried camellia seeds that have been pulverized, put them in a 500 ml beaker, add 150 ml of n-hexane, stir for 2 hours to obtain camellia oil, collect and utilize the camellia oil, and dry the remaining ingredients to obtain camellia meal;

[0030] S3. Extraction of tea saponin: crush the dried camellia meal, put the crushed camellia meal into a conical flask, add 150-300ml of compound extraction solvent, extr...

Embodiment 2

[0033] The optimization of embodiment 2 composite extraction solvent proportioning

[0034] a) Optimization of compound extraction solvent components

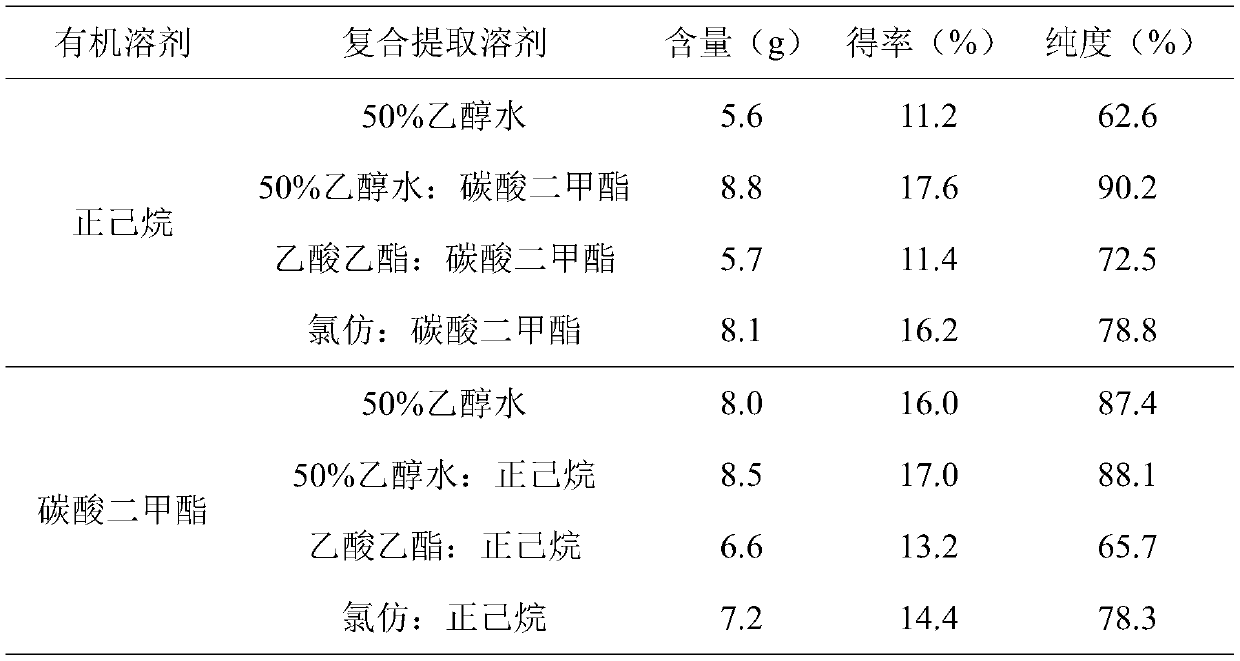

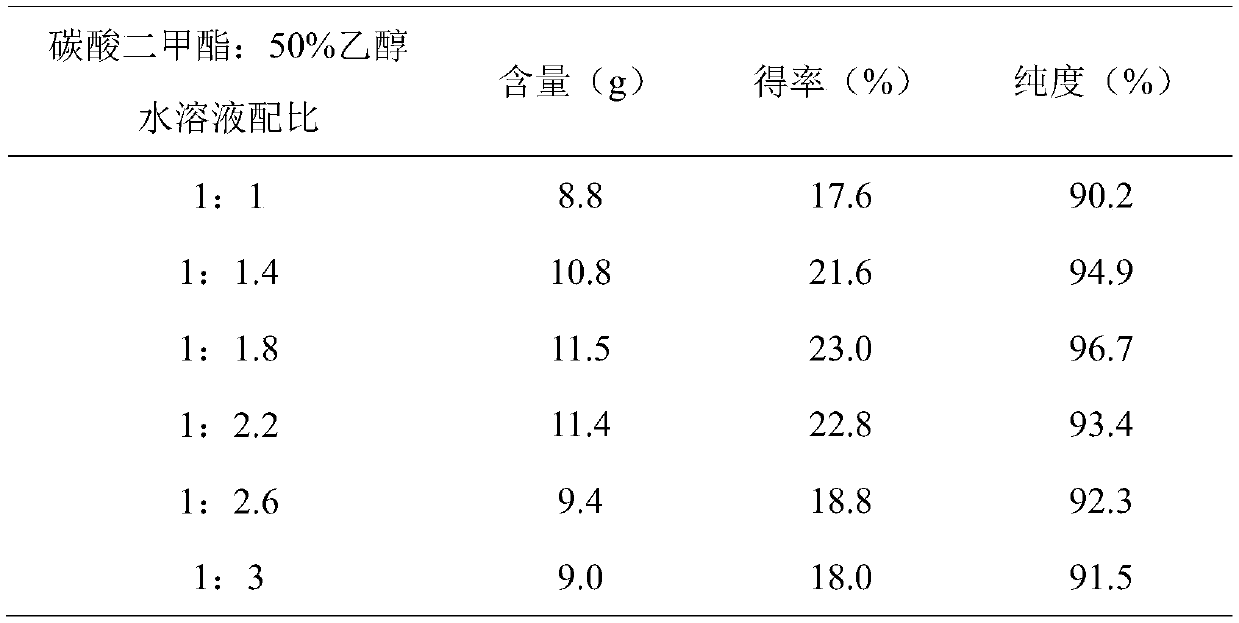

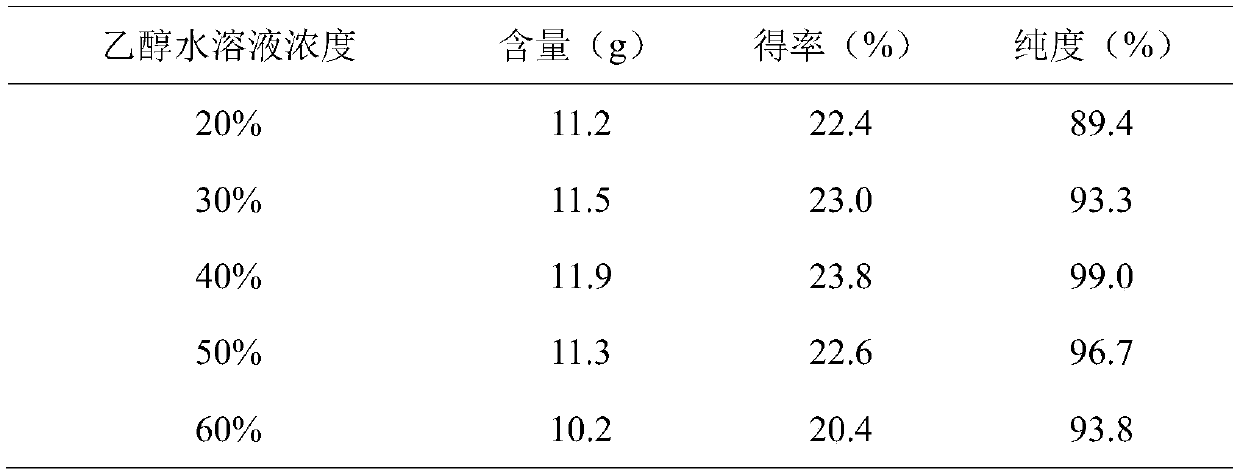

[0035] The type of extraction solvent will have certain influence on the content and yield of tea saponin. Select different degreasing organic solvents (n-hexane, dimethyl carbonate) and extraction solvents (ethyl acetate, ethanol, chloroform, 50% ethanol water) and dimethyl carbonate in a ratio of 1:1 to compound, as in Example 1 Tea saponin was extracted according to the following steps, and the content and purity of tea saponin were determined by vanillin-concentrated sulfuric acid colorimetry (You Ruiyun, Zheng Shanyu, Chen Rong, et al. Research on the extraction process of tea saponin from longan tea dregs[J]. Applied Chemical Industry, 2015, 000(009):1635-1638.). The effects of different compound extraction solvents on the yield and purity of tea saponin were investigated.

[0036] The obtained tea saponin quality of t...

Embodiment 3

[0049] The optimization of embodiment 3 extraction temperature

[0050] The compound extraction solvent is dimethyl carbonate: 40% ethanol aqueous solution ratio of 1:1.8, extract tea saponin at different temperatures according to the steps of Example 1, and investigate the influence of temperature on the yield and purity of tea saponin.

[0051] The tea saponin quality obtained under the different temperature conditions of table 4

[0052]

[0053] Through a series of experiments, it can be seen that within a certain temperature range, as the temperature increases, the yield of tea saponin will increase, and the color will also deepen. However, as the temperature continues to increase, the yield of tea saponin will increase. Therefore, 60°C is the most suitable extraction temperature. Under this temperature condition, the quality of tea saponin is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com