Method for preparing gentiosaccharide oligosaccharides by using β-1,6-glucanase and its application

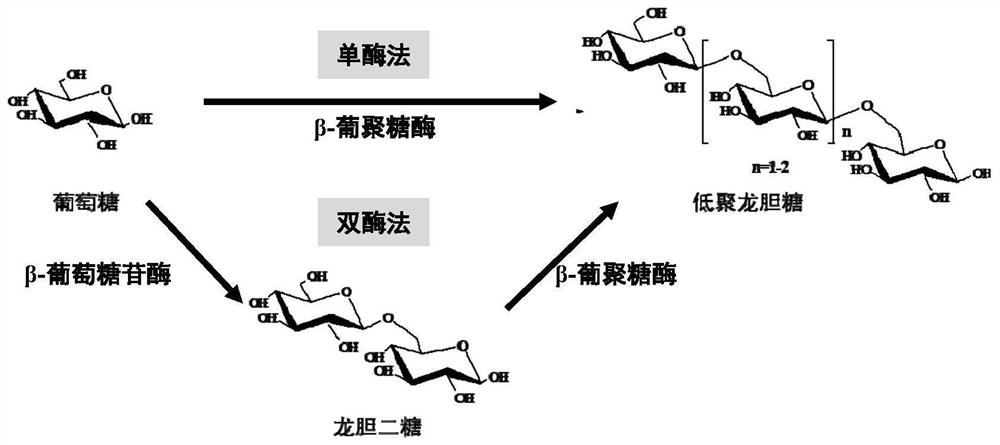

A technology of gentiooligosaccharides and glucanase, which is applied in the field of preparation of gentiooligosaccharides, and can solve the problem of undetected gentiotriose oligosaccharide components and low yield of gentiooligosaccharides , high cost of enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Construction of β-1,6 glucanase and β-glucosidase Pichia genetically engineered bacteria

[0052] (1) Construction of β-1,6 glucanase Pichia genetically engineered bacteria

[0053] The gene encoding β-1,6-glucanase TcBgn (nucleotide sequence shown in SEQ ID NO. 3) was chemically synthesized and linked with the Pichia pastoris expression vector pPIC9K to obtain the recombinant plasmid pPIC9K-TcBgn and transferred into Escherichia coli JM109 In the middle, after the digestion verification, the recombinant plasmid pPIC9K-TcBgn was electro-transformed into Pichia pastoris KM71, and then the transformation solution was spread on the MD plate, and a single clone was grown on the MD plate, and then 96 transformants were picked and transferred to The transformants with higher enzyme activity were screened on a new MD plate and a 10 mL tube was used to obtain the β-1,6 glucanase Pichia pastoris genetically engineered bacteria.

[0054] Primers used for PCR amplifica...

Embodiment 2

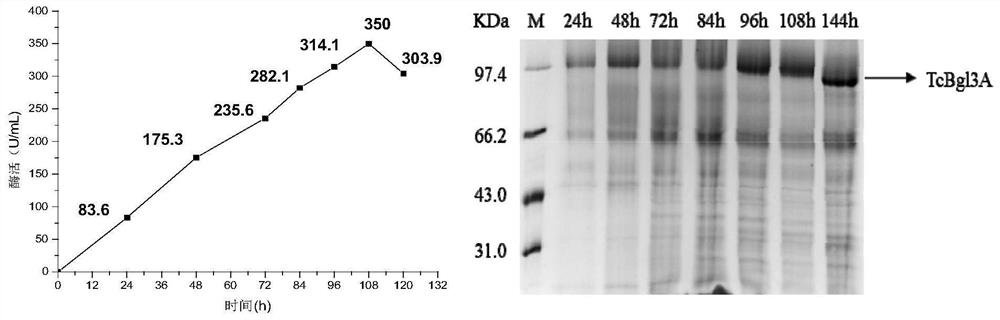

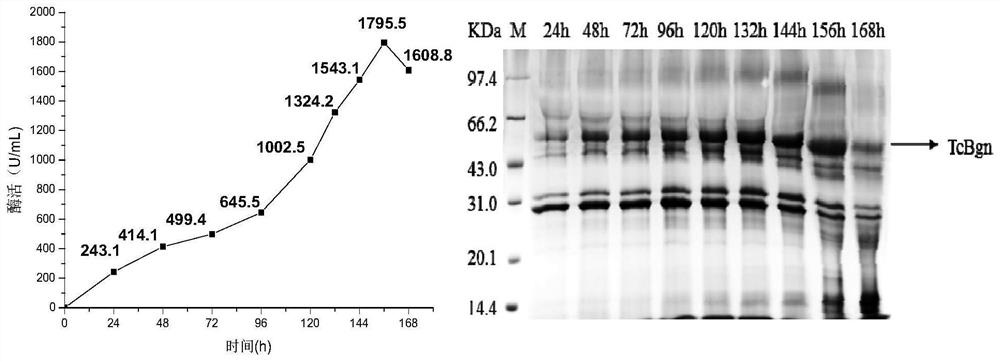

[0059] Example 2: Production of β-glucosidase and β-1,6-glucanase by 3.6L tank fermentation

[0060] (1) The β-1,6 glucanase Pichia genetically engineered bacteria and the β-glucosidase Pichia genetically engineered bacteria prepared in Example 1 were inoculated into YPD medium, respectively, at 30° C., 200 rpm Cultivated for 24h, cultivated to the OD of the seed liquid 600 is 1.3-1.5.

[0061] (2) Batch fermentation stage: the seed liquid is inoculated into the fermenter with 8%-12% inoculation amount, and the temperature is controlled at 28-30°C, the initial rotation speed is 180-220rpm, the initial ventilation rate is 7L / min, and the dissolved oxygen is 28-32 %, pH 4.5-5.5;

[0062] (3) Feed-feed fermentation stage: when the dissolved oxygen rises to 80-100%, feed-feed culture is carried out by adding glycerol at a constant speed, and the temperature is controlled at 28-30°C, dissolved oxygen at 28-32%, and pH at 4.5-5.5;

[0063] (4) Induction culture stage: when the ba...

Embodiment 3

[0076] Example 3: Enzymatic properties of β-glucosidase

[0077] The obtained β-glucosidase enzyme solution is subjected to enzymatic characterization with the above-mentioned enzyme activity assay method, and the enzyme activity is measured at different temperatures with pNPG as a substrate. The results show that the optimum temperature of β-glucosidase is Then, different pH gradients were set to measure the enzymatic activity of β-glucosidase under the optimum temperature conditions, and the optimum pH of the enzyme was obtained as 4.5 ( Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com