High-platinum-metal-content silver-palladium bonding wire and preparation process thereof

A preparation process and bonding wire technology, which is applied in the field of silver-platinum bonding wire with high platinum content and its preparation process, can solve the problems of poor high-temperature oxidation resistance, easy migration of silver ions, and low tensile strength. Achieve the effect of improving plasticity and toughness, high radian and good tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

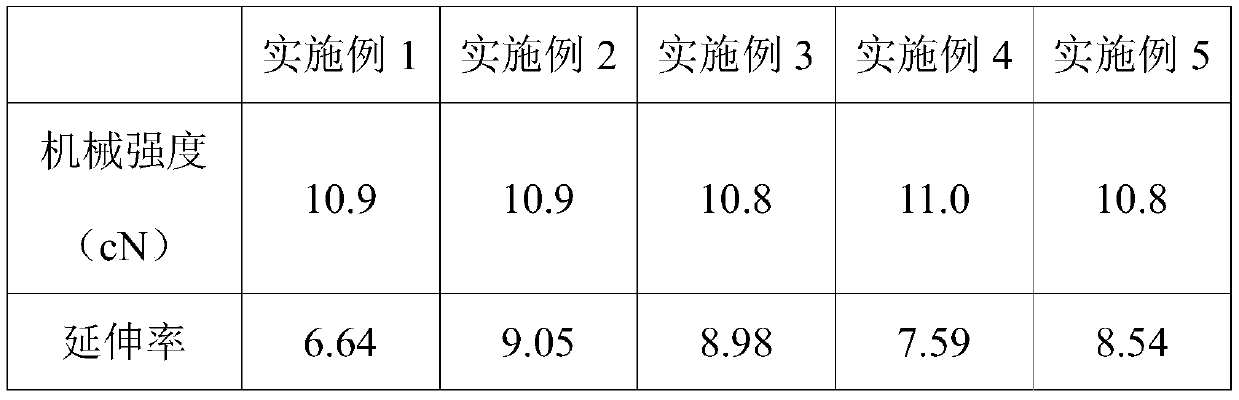

Embodiment 1

[0028] A preparation process of silver-platinum bonding wire with high platinum content:

[0029] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0030] 2) Preparation of silver-platinum alloy: take 45% silver and 19.874% platinum metal and place them in a hydrogen atmosphere, dope with 0.08% indium element, carry out vacuum melting, the melting temperature is 1170°C, and water-cooled casting to obtain silver-platinum alloy;

[0031] 3) Preparation of silver-copper-chromium alloy: Take 20% silver, 0.05% copper and 0.007% chromium metal in an argon atmosphere, dope 0.003% iridium element, carry out vacuum melting, the melting temperature is 1700 ° C, and water-cooled casting to obtain silver copper chromium alloy;

[0032] 4) Preparation of silver-calcium alloy: Take 15% silver and 0.06% calcium metal in an argon atmosphere, dope with 0.003% lanthanum element, carry out vacuum melting, the melting temperature is 2650 ° C, and water-cooled cas...

Embodiment 2

[0037] A preparation process of silver-platinum bonding wire with high platinum content:

[0038] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0039] 2) Preparation of silver-platinum alloy: take 52% silver and 14.105% platinum metal and put them in a hydrogen atmosphere, dope with 0.006% indium element, carry out vacuum melting, the melting temperature is 1170°C, and water-cooled casting to obtain silver-platinum alloy;

[0040] 3) Preparation of silver-copper-chromium alloy: Take 21% silver, 0.2% copper and 0.01% chromium metal in an argon atmosphere, dope 0.007% iridium element, carry out vacuum melting, the melting temperature is 1750 ° C, and water-cooled casting to obtain silver copper chromium alloy;

[0041] 4) Preparation of silver-calcium alloy: Take 12.4% silver and 0.28% calcium metal in an argon atmosphere, dope with 0.008% lanthanum element, carry out vacuum melting, the melting temperature is 2700 ° C, and water-cooled cast...

Embodiment 3

[0046] A preparation process of silver-platinum bonding wire with high platinum content:

[0047] 1) Raw material pretreatment: wash the metal raw material, dry it for later use;

[0048] 2) Preparation of silver-platinum alloy: take 54% silver and 7.99% platinum metal and put them in a hydrogen atmosphere, dope with 0.08% indium element, carry out vacuum melting, the melting temperature is 1180°C, and water-cooled casting to obtain silver-platinum alloy;

[0049] 3) Preparation of silver-copper-chromium alloy: take 25% silver, 0.2% copper and 0.01% chromium metal in an argon atmosphere, dope 0.007% iridium element, carry out vacuum melting, the melting temperature is 1780 ° C, and water-cooled casting to obtain silver copper chromium alloy;

[0050] 4) Preparation of silver-calcium alloy: Take 15.55% silver and 0.23% calcium metal in an argon atmosphere, dope with 0.007% lanthanum element, carry out vacuum melting, the melting temperature is 2750 ° C, and water-cooled castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com