Cigarette cooling gel particles and application thereof

A technology of gel particles and cigarettes, applied in the application, tobacco, smoke oil filter and other directions, to achieve the effects of reducing temperature, improving heat absorption capacity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 10g of polyvinyl alcohol 1788 (polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 88%) and add it to 100g of deionized water to prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 10%, mechanically stirring at 95°C After the polyvinyl alcohol is completely dissolved, add 10 g of polyethylene glycol 4000, mechanically stir for 2 hours to form a uniform dispersion system, and stand at 60 ° C for 30 minutes for defoaming. Then pour the uniformly dispersed system into a stainless steel mold, freeze at -20°C for 12 hours, and thaw at room temperature for 6 hours. This freeze-thaw is a cycle. After 3 cycles, the polyvinyl alcohol cross-linked gel system is obtained. The polyvinyl alcohol cross-linked gel system is lyophilized to remove ionized water, and finally crushed into particles of about 20 meshes to obtain cigarette cooling gel particles.

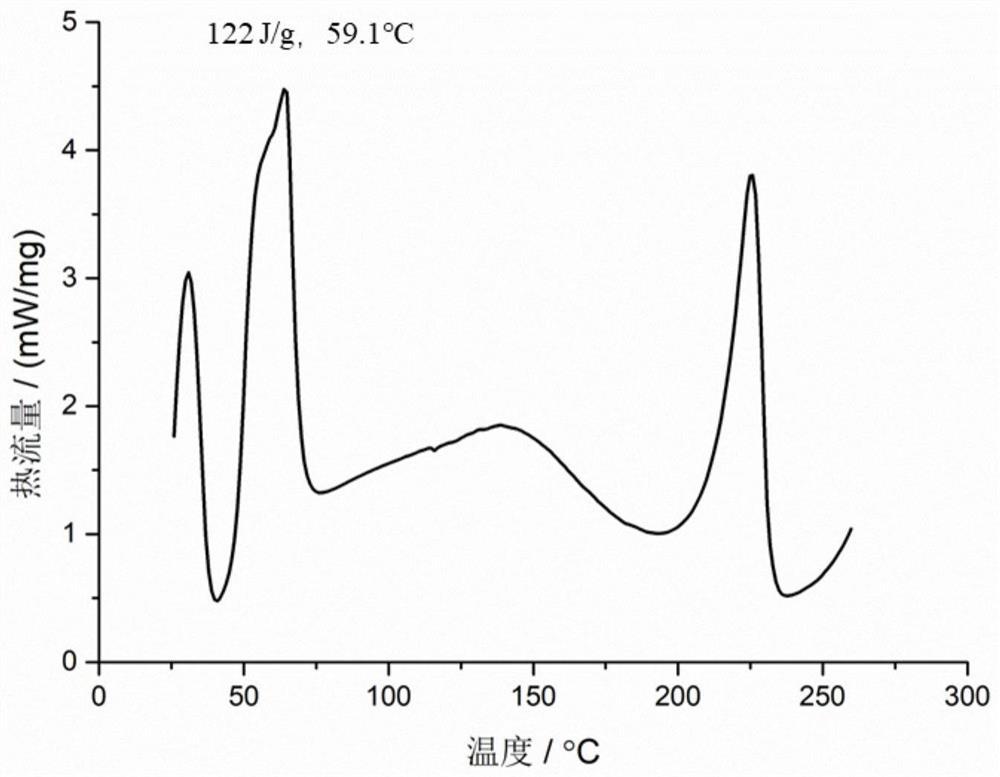

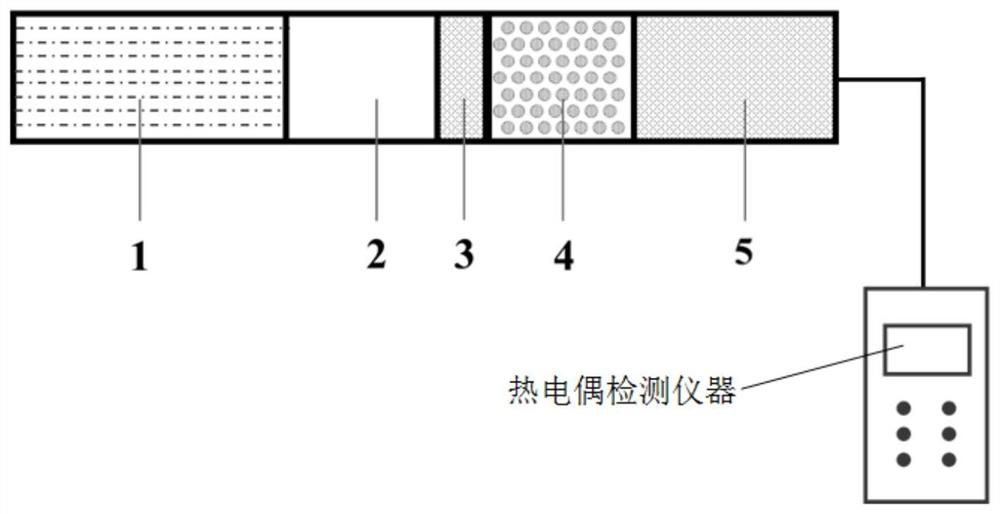

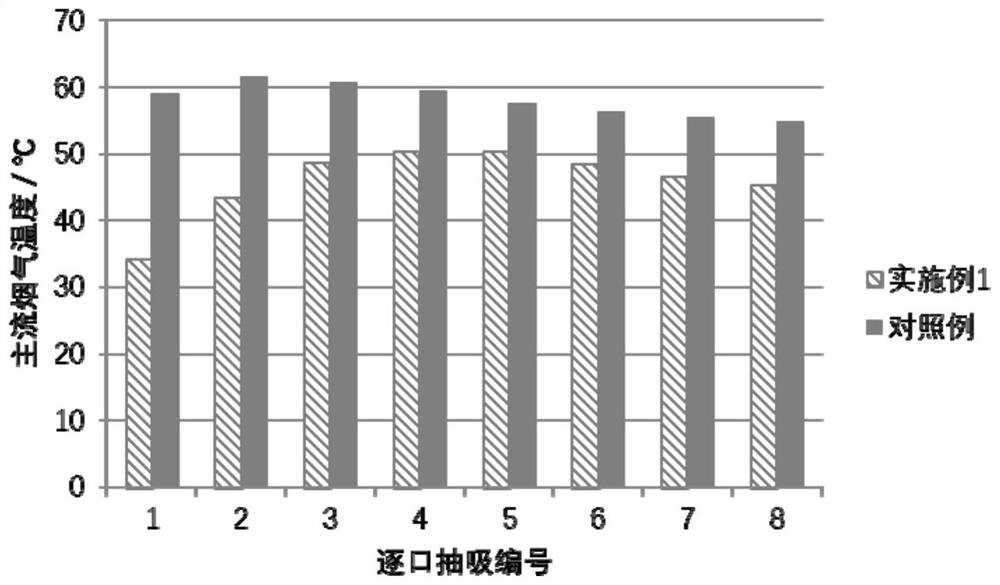

[0043] The DSC curve of cigarette cooling gel particles is as fol...

Embodiment 2

[0046] Weigh 10g of polyvinyl alcohol 1799 (polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 99%) and add it to 190g of deionized water to prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 5%, mechanically stirring at 95°C After the polyvinyl alcohol is completely dissolved, add 10g of polyethylene glycol 2000 and 10g of erythritol, mechanically stir for 2 hours to form a uniform dispersion system, and stand at 60°C for 30 minutes for defoaming. Then pour the uniformly dispersed system into a stainless steel mold, freeze at -20°C for 12 hours, and thaw at room temperature for 6 hours. This freeze-thaw is a cycle. After 5 cycles, the polyvinyl alcohol cross-linked gel system is obtained. The polyvinyl alcohol cross-linked gel body is freeze-dried to remove water, and finally crushed into particles of about 20 meshes to obtain cigarette cooling gel particles.

[0047] Weigh 120 mg / piece of cooling particles to prepar...

Embodiment 3

[0049] Weigh 40g of polyvinyl alcohol 1790 (polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 90%) and add it to 460g of deionized water to prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 8%, mechanically stirring at 95°C , after polyvinyl alcohol is completely dissolved, add 80g polyethylene glycol 8000 and 40g xylitol, obtain uniform dispersion system after mechanical stirring 4 hours, add mass fraction in uniform dispersion system and be 1% borax aqueous solution 500g, stir half After fully completing the gelation reaction of polyvinyl alcohol and borax within 1 hour, the polyvinyl alcohol cross-linked gel system was obtained. After standing at 60°C for 30 minutes, the polyvinyl alcohol cross-linked gel system was removed under freeze-drying conditions. water, and finally crushed into particles of about 30 meshes to obtain cigarette cooling gel particles.

[0050] Weigh 150 mg / piece of cooling particles to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com