Passivator and preparation method thereof

A technology of passivating agent and crosslinking agent, which is applied in the fields of metal refining, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of antimony loss, deposition, and human health effects, and achieve the effect of effective removal and enhanced adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

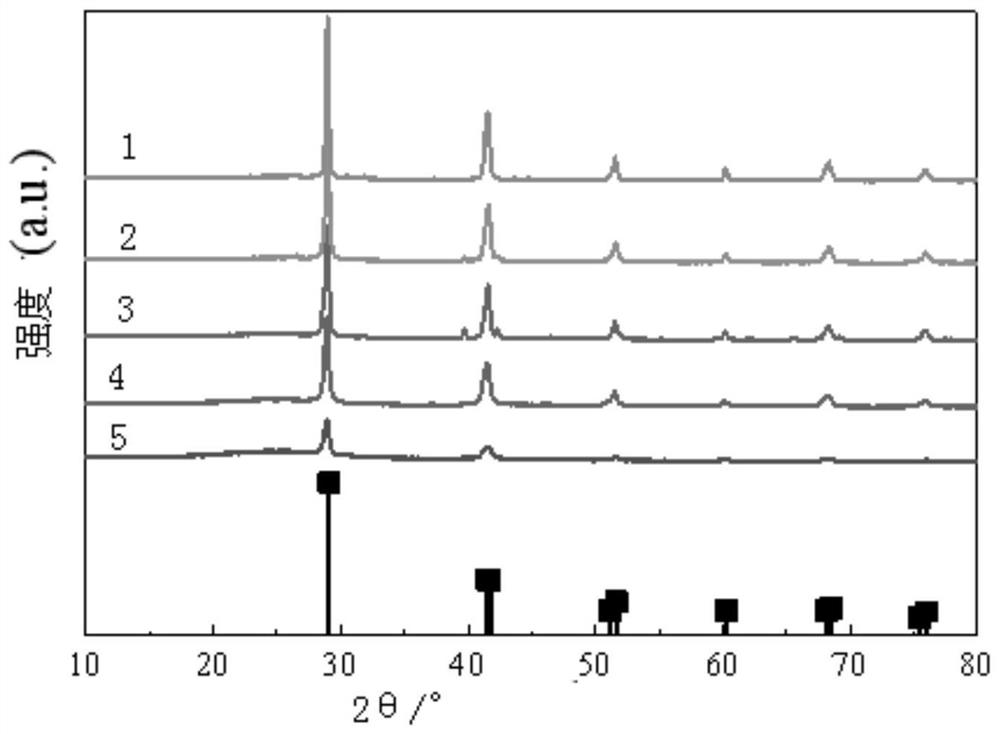

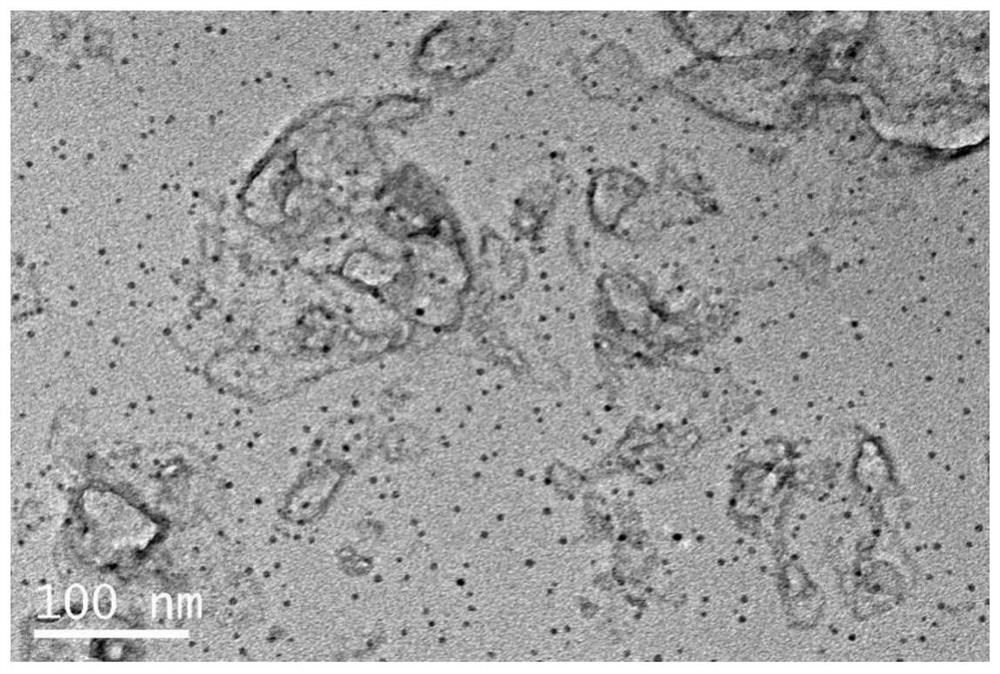

Image

Examples

preparation example Construction

[0031] For the solution looking for the substitute of antimony base passivator, the invention provides a kind of preparation method of passivator, comprises the steps:

[0032] S1: Mix antimony salt, tin salt and aromatic hydrocarbon solvent to form a first solution;

[0033] S2: adding a crosslinking agent to the first solution, and reacting at 0°C to 10°C to obtain a second solution;

[0034] S3: adding organic amine and deionized water to the second solution in sequence, stirring and reacting at 50° C. to 100° C. to obtain a mixture;

[0035] S4: heating and evaporating the mixture at 90°C to 180°C to obtain a solid intermediate product;

[0036] S5: calcining the solid intermediate product at 500° C. to 800° C. to obtain a passivating agent.

[0037] This application uses antimony salts and tin salts as raw materials. Compared with oxides as raw materials, since the properties of antimony salts and tin salts are more stable, there is no need to add additional stabilizers...

Embodiment 1

[0061] The present embodiment provides a kind of preparation method of passivating agent, comprises the steps:

[0062] S1: Dissolving 10g of antimony trichloride and 10g of tin tetrachloride in 40g of benzene to form a first solution;

[0063] S2: Take 5ml (about 7.1g) of chloroacetyl chloride and slowly drop it into the first solution, control the temperature at 0°C, and the reaction time for 30min to obtain the second solution;

[0064] S3: Measure 5ml (about 4.5g) of ethylenediamine, add it dropwise to the second solution, then measure 5ml deionized water, add it dropwise to the second solution, heat and stir, and stir magnetically at 100°C. The rotational speed of magnetic stirring is 500 rpm, reacted for 2h to obtain a mixture;

[0065] S4: heating and evaporating the mixture at 90° C. for 6 h to obtain a solid intermediate product;

[0066] S5: Put the solid intermediate product into a high-temperature furnace, raise the temperature to 500° C. at a heating rate of 1° ...

Embodiment 2

[0070] The present embodiment provides a kind of preparation method of passivating agent, comprises the steps:

[0071] S1: Dissolving 15g of phenylantimony and 15g of alkyltin in 80g of ethylbenzene to form a first solution;

[0072] S2: Take 10ml (about 12.35g) of 1,2-dichloroethane and slowly add it dropwise to the first solution, control the temperature at 5°C, and react for 60 minutes to obtain the second solution;

[0073] S3: Measure 5ml of triethylamine (about 3.65g), add it dropwise to the second solution, then measure 10ml of deionized water, add it dropwise to the second solution, heat and stir, and magnetically stir at 90°C, the speed of magnetic stirring is 5000 rpm, reacted for 3h to obtain the mixture;

[0074] S4: heating and evaporating the mixture at 120° C. for 16 h to obtain a solid intermediate product;

[0075] S5: Put the solid intermediate product into a high-temperature furnace, raise the temperature to 600° C. at a heating rate of 5° C. / min, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com