Self-heat-release high-potential cathode material for thermal battery and preparation method of self-heat-release high-potential cathode material

A cathode material and thermal battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the specific capacity of the battery, the reduction of output capacity, and the high reactivity, so as to improve the conductivity and ion mobility, and reduce the effect of Time, the effect of inhibiting the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

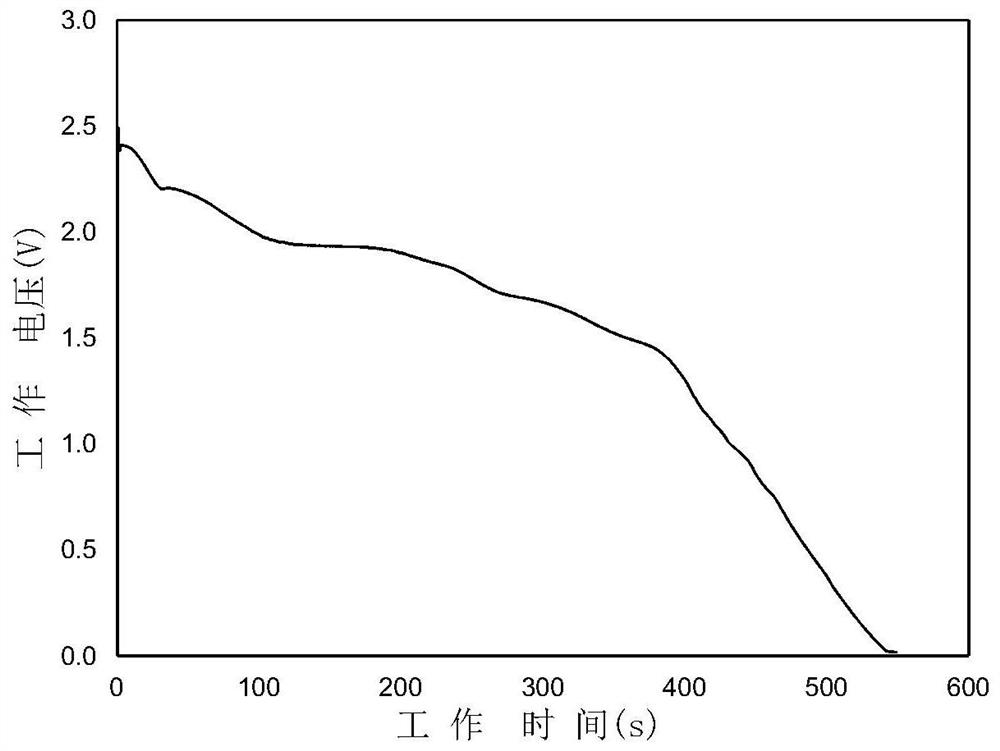

[0035]Put 30g Cu simple substance, 30g potassium perchlorate and 5g LiCl-KCl-CsBr depolarizer in the container, under the protection of an inert atmosphere and a dry environment, mechanically mix and ball mill for 30min, pass through an 80 mesh sieve, and then add 10g Fe to support the combustion agent and 1g of carbon nanotube conductive agent, and mechanically mixed ball milling for 30min, and passed through an 80-mesh sieve to obtain; then the powder was used as a cathode, and a low-melting-point electrolyte and a LiB anode were used to assemble a thermal battery, and the thermal battery was discharged at a constant current of 1A ( 10mA / cm 2 ), the peak voltage reaches 2.49V, the test results are as follows figure 1 .

Embodiment 2

[0037] Put 35g Cu simple substance, 35g potassium perchlorate and 4g LiCl-KCl-CsBr depolarizer in the container, under the protection of inert atmosphere and dry environment, after mechanical mixing and ball milling for 30min, pass through 80 mesh sieve, then add 15g Fe to support combustion agent and 1g of carbon nanotube conductive agent, and mechanically mixed ball milling for 30min, and passed through an 80-mesh sieve to obtain; then the powder was used as a cathode, and a low-melting-point electrolyte and a LiB anode were used to assemble a thermal battery, and the thermal battery was discharged at a constant current of 1A ( 10mA / cm 2 ), the peak voltage reaches 2.51V.

Embodiment 3

[0039] Put 40g Cu simple substance, 30g potassium perchlorate and 5g LiCl-KCl-CsBr depolarizer in the container, under the protection of an inert atmosphere and a dry environment, mechanically mix and ball mill for 30min, pass through an 80 mesh sieve, and then add 15g Fe to support the combustion agent and 1g of carbon nanotube conductive agent, and mechanically mixed ball milling for 30min, and passed through an 80-mesh sieve to obtain; then the powder was used as a cathode, and a low-melting-point electrolyte and a LiB anode were used to assemble a thermal battery, and the thermal battery was discharged at a constant current of 1A ( 10mA / cm 2 ), the peak voltage reaches 2.43V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com