Preparation method of composite metal material catalyst and its application in the preparation of 5-hmf

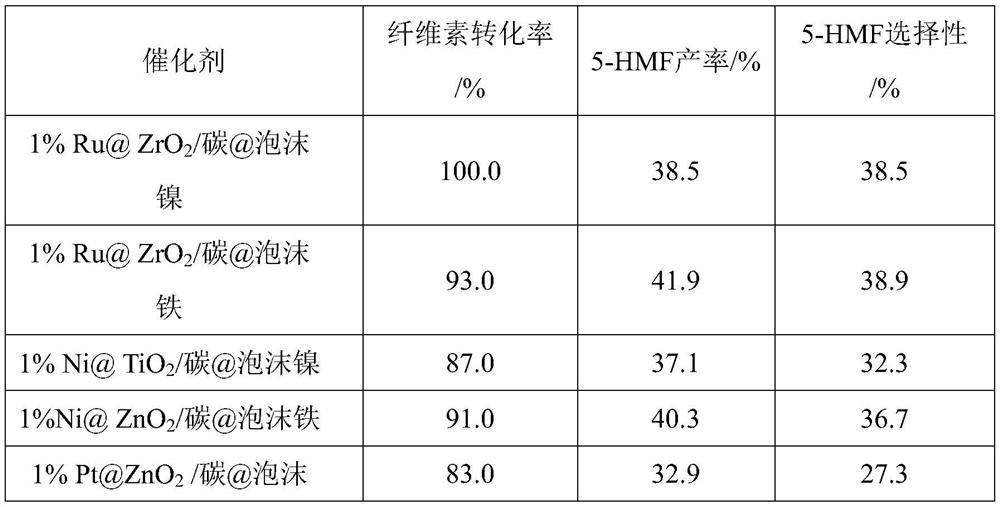

A composite metal material and 5-HMF technology, applied in the field of biomass resource utilization, can solve the problems of uneven heating of cellulose, complex by-products, high energy consumption, etc., and achieve easy recycling, simple production methods, and reduced fouling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

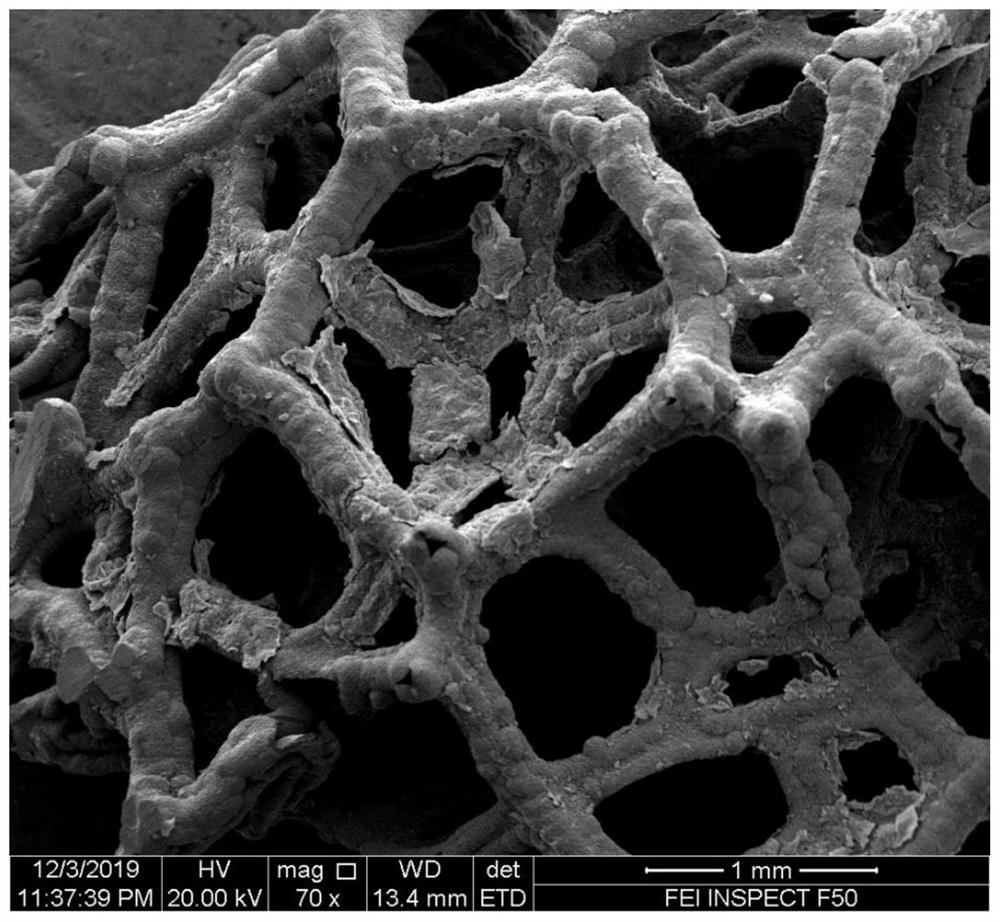

[0030]Pretreatment of metal foam: Soak nickel foam in 1mol / L hydrochloric acid for 30 minutes to remove oxides on its surface. The product is washed with deionized water and ethanol three times, and dried under vacuum at 40°C;

Embodiment 2

[0032] Dissolve 0.93g of zirconium tetrachloride and 2.8g of 2-aminoterephthalic acid in 150ml of DMF to form a solution, and place 12mm*6mm*1.5mm of pretreated foam iron in it, and stir at 80°C After 30 minutes, the whole mixture was transferred into a polytetrafluoroethylene container, put into a hydrothermal reaction kettle, reacted at 120°C for 36 hours, cooled down, filtered, stirred and washed twice with ethanol, and dried by filtration.

Embodiment 3

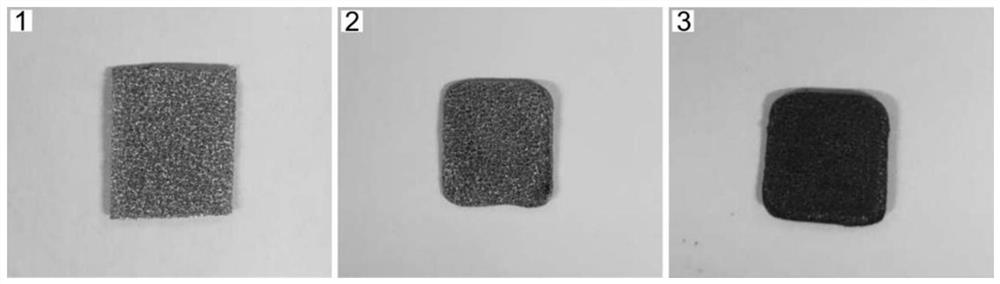

[0034] Take 10.0g of nickel foam with Zr-MOF (UiO-66) growth in 100mL of deionized water, then add 6ml of RuCl with a concentration of 0.05g / ml 3 solution, stirred at room temperature for 60min, then added 8ml of prepared 6mol / L NaBH 4 The solution was reduced, and the stirring was continued for 3 hours. After the obtained suspension was centrifuged, washed, and vacuum-dried, it was calcined at 600°C for 4 hours under an oxygen-barrier condition, and a composite metal material based on metal foam was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com