Ti(CN)-based self-lubricating cermet cutter material added with alumina-coated calcium fluoride composite powder and preparation method thereof

A technology of coating calcium fluoride and composite powder, which is applied in the preparation of alumina/hydroxide, alumina/aluminum hydroxide, calcium/strontium/barium fluoride, etc., can solve the problem of poor mechanical properties of self-lubricating ceramic tools , reduce the mechanical properties such as tool material strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A Ti(CN)-based self-lubricating cermet tool material added with alumina-coated calcium fluoride composite powder is formed by hot-pressing and sintering the following main raw materials in mass percentages:

[0056] 3% of alumina-coated calcium fluoride composite powder, 0.36% of magnesium oxide, 8.6% of molybdenum, 15% of nickel, 15% of cobalt, and the rest is Ti(CN); the sum of the mass percentages of each component is 100%.

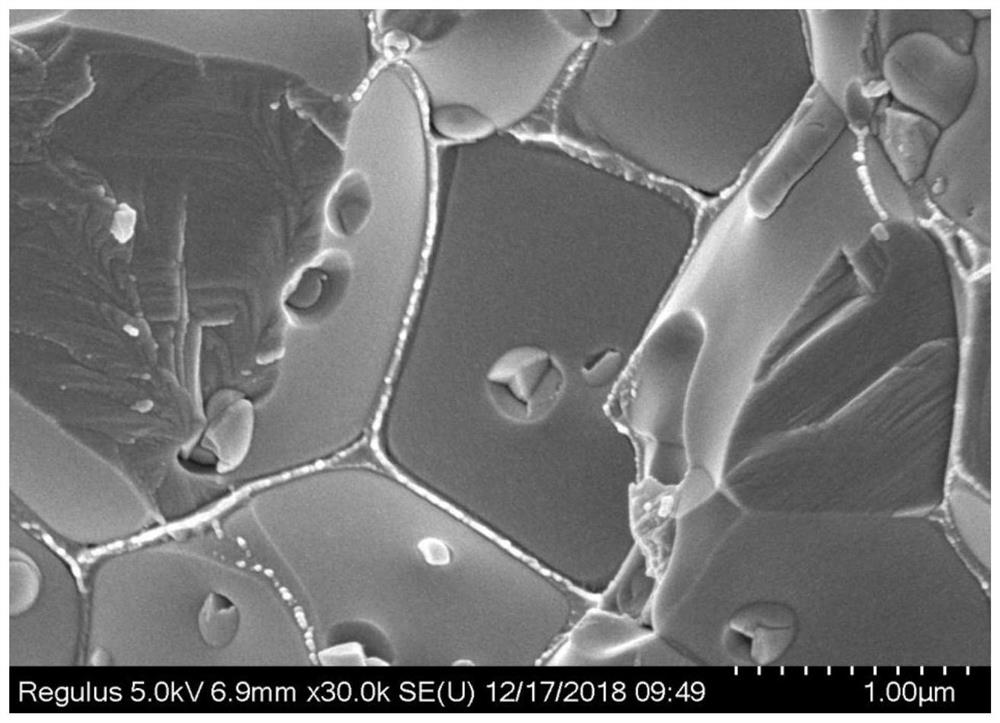

[0057] The average particle size of the alumina-coated calcium fluoride composite powder is 50 nm, the average particle size of Ti(CN) is 50 μm, the average particle size of molybdenum is 15 μm, the average particle size of cobalt is 15 μm, and the average particle size of nickel The diameter is 15 μm, and the average particle diameter of magnesium oxide is 0.5 μm.

[0058] The preparation steps are as follows:

[0059] (1) Add 0.2 g of polyethylene glycol (weight average molecular weight 4000) into 300 mL of absolute ethanol for ultrasonic dis...

Embodiment 2

[0066] A Ti(CN)-based self-lubricating cermet tool material added with alumina-coated calcium fluoride composite powder is formed by hot-pressing and sintering the following main raw materials in mass percentages:

[0067] Aluminum oxide coated calcium fluoride composite powder 6%, magnesium oxide 0.37%, molybdenum 8.7%, nickel 15.2%, cobalt 15.2%, and the rest is Ti(CN); the sum of the mass percentages of each component is 100%.

[0068] The average particle size of the alumina-coated calcium fluoride composite powder is 50 nm, the average particle size of Ti(CN) is 50 μm, the average particle size of molybdenum is 15 μm, the average particle size of cobalt is 15 μm, and the average particle size of nickel The diameter is 15 μm, and the average particle diameter of magnesium oxide is 0.5 μm.

[0069] The preparation steps are as follows:

[0070] (1) Add 0.2 g of polyethylene glycol (weight average molecular weight 4000) into 300 mL of absolute ethanol for ultrasonic dispers...

Embodiment 3

[0077] A Ti(CN)-based self-lubricating cermet tool material added with alumina-coated calcium fluoride composite powder is formed by hot-pressing and sintering the following main raw materials in mass percentages:

[0078] Calcium fluoride composite powder coated with alumina is 9%, magnesium oxide is 0.37%, molybdenum is 8.8%, nickel is 15.4%, cobalt is 15.4%, and the rest is Ti(CN); the sum of the mass percentages of each component is 100%.

[0079] The average particle size of the alumina-coated calcium fluoride composite powder is 50 nm, the average particle size of Ti(CN) is 50 μm, the average particle size of molybdenum is 15 μm, the average particle size of cobalt is 15 μm, and the average particle size of nickel The diameter is 15 μm, and the average particle diameter of magnesium oxide is 0.5 μm.

[0080] The preparation steps are as follows:

[0081] (1) Add 0.2 g of polyethylene glycol (weight average molecular weight 4000) into 300 mL of absolute ethanol for ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com