Membrane silk moisturizing composition and preparation method and application thereof

A technology of composition and membrane silk, which is applied in the direction of textiles and papermaking, biochemical fiber treatment, fiber type, etc., can solve the problems of difficult washing and poor anti-firing performance of membrane silk moisturizing composition, and achieve improved moisturizing effect and anti-aging Oxidizing, fast-rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

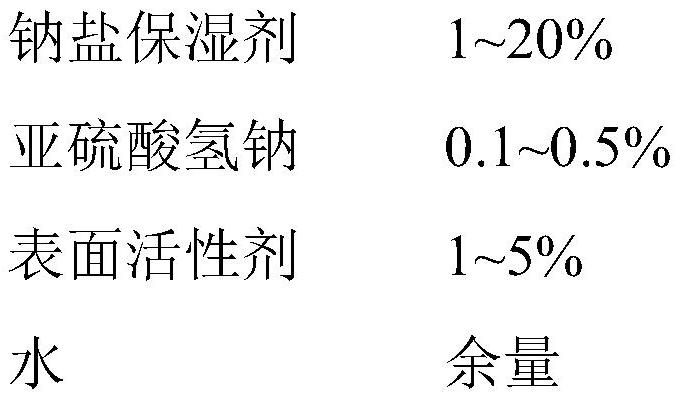

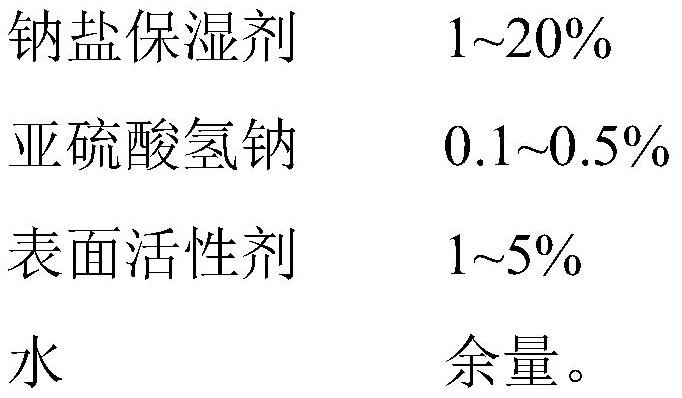

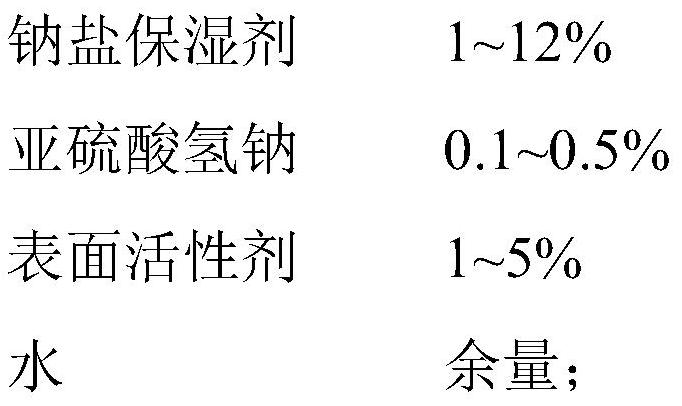

Method used

Image

Examples

Embodiment 1

[0046] In the cleaning pool, sodium acetate, water, sodium bisulfite and lauryl dimethyl betaine are prepared in a mass ratio of 5:91.8:0.2:3 at a water temperature of 40°C to prepare a film silk moisturizing composition, specifically as follows Steps: Weigh sodium acetate, water, sodium bisulfite and alkyl dimethyl betaine in proportion; first take a part of pure water and heat it to a constant temperature of 40°C, add sodium acetate and alkyl dimethyl betaine, stir and mix evenly, Then ultrasonicate the sodium bisulfite in an ultrasonic oscillator for 20 minutes, after the sodium bisulfite is evenly dispersed, slowly add it into the mixed solution of sodium acetate, alkyl dimethyl betaine and water, add the remaining pure water and stir evenly , until the solution becomes a transparent and uniform solution, it can be cooled and used.

[0047] Put the entire bundle of membrane filaments into a tank filled with the membrane filament moisturizing composition prepared above, soa...

Embodiment 2

[0053] In the cleaning pool, sodium hyaluronate, water, sodium bisulfite and sodium lauryl sulfate are prepared in a mass ratio of 10:87.7:0.3:2 at a water temperature of 35°C to prepare a film silk moisturizing composition, which specifically includes the following steps : Weigh sodium hyaluronate, water, sodium bisulfite and sodium lauryl sulfate in proportion; first take a part of pure water and heat it to a constant temperature of 40°C, add sodium hyaluronate and sodium lauryl sulfate, stir and mix well , then sonicate the sodium bisulfite in an ultrasonic oscillator for 20 minutes, after the sodium bisulfite is evenly dispersed, slowly add it into the mixed solution of sodium hyaluronate, sodium lauryl sulfate and water, and add the remaining pure water Stir evenly until the solution becomes a transparent and uniform solution, then it can be cooled and used.

[0054] Put the entire bundle of membrane filaments into a tank filled with the membrane filament moisturizing com...

Embodiment 3

[0060] In the cleaning pool, sodium lactate, water, sodium bisulfite and octadecyltrimethylammonium chloride are mixed in a mass ratio of 8:88.9:0.1:3 to prepare a membrane silk moisturizing composition at a water temperature of 30°C, specifically as follows Steps: Weigh sodium lactate, water, sodium bisulfite and octadecyl trimethyl ammonium chloride in proportion; first take a part of pure water and heat it to a constant temperature of 40°C, add sodium lactate and octadecyl trimethyl ammonium chloride, Stir and mix evenly, then ultrasonically ultrasonicate the sodium bisulfite for 20 minutes in an ultrasonic oscillator. After the sodium bisulfite is uniformly dispersed, slowly add it into the mixed solution of sodium lactate, octadecyltrimethylammonium chloride and water, add Stir the remaining pure water evenly until the solution becomes a transparent and uniform solution, then it can be cooled and used.

[0061] Put the entire bundle of membrane filaments into a tank fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com