Compound, hole transport material and organic electroluminescent device

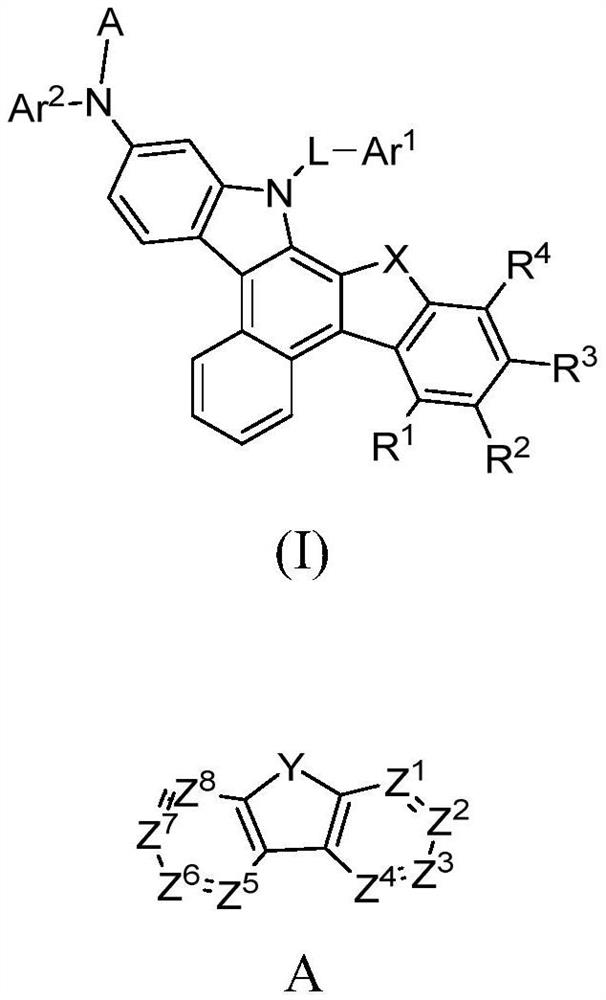

A compound and chemical bond technology, applied in the field of organic electroluminescent devices, can solve the problems of OLED display device display function, low hole migration rate, poor energy level matching, etc., which restrict OLED luminous efficiency, achieve excellent display effect and improve luminous efficiency , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

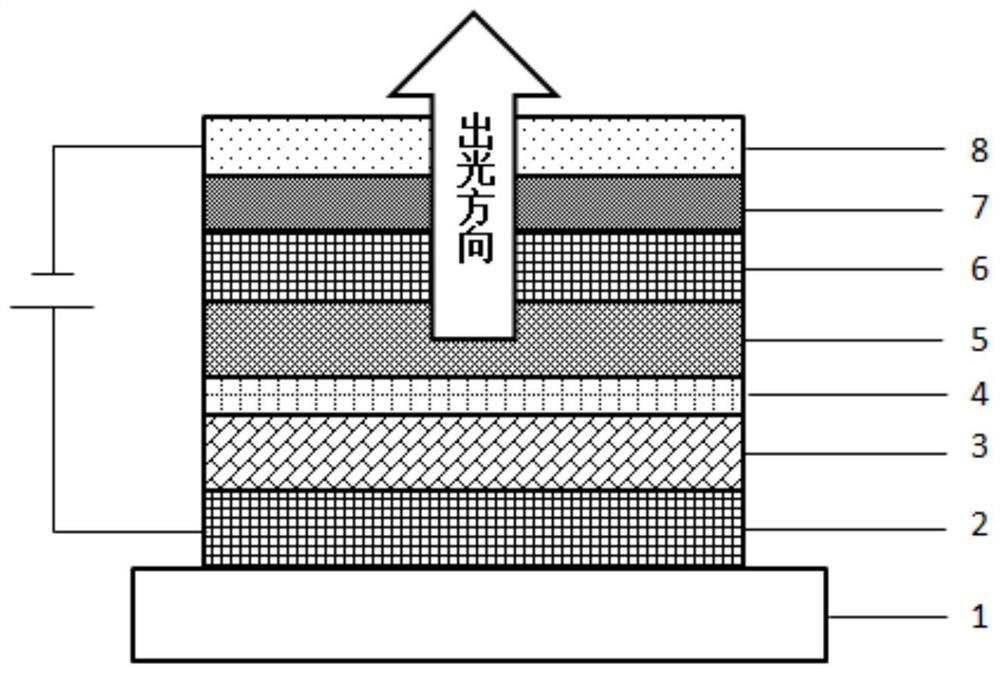

[0153] The glass plate coated with the ITO transparent conductive layer is ultrasonically treated in a commercial cleaning agent, rinsed in deionized water, ultrasonically degreased in acetone-ethanol mixed solvent, baked in a clean environment until the water is completely removed, and then cleaned with ultraviolet light. Light and ozone cleaning, and bombardment of the surface with a beam of low-energy cations;

[0154] Then, the above-mentioned glass substrate with the anode is placed in a vacuum chamber, and the vacuum is evacuated to less than 10 -5 Torr, on the above-mentioned anode layer film vacuum evaporation hole injection layer, hole injection layer material is HT-11 and the p-type dopant (p-dopant) that mass ratio is 3%, wherein, evaporation rate is 0.1 nm / s, the evaporated film thickness is 10nm, the material and p-type dopant of the hole injection layer are:

[0155]

[0156] Then, the hole transport material A1 material is vacuum-evaporated on the hole injec...

Embodiment 2-7

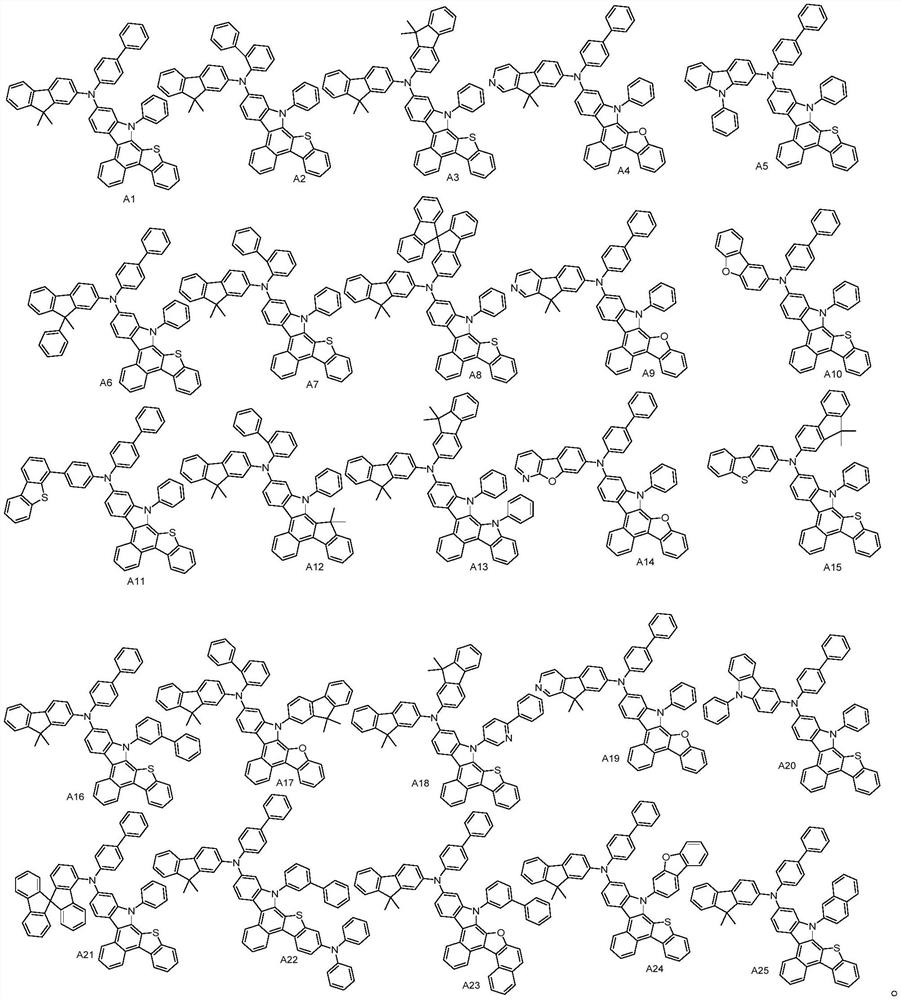

[0165] Except that A1 is replaced by A5, A12, A13, A14, A15, and A23 respectively, the rest is the same as in Example 1. See Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com