High-activity straw biochar and preparation method thereof

A technology of straw biology and high activity, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficult control of pore structure, high equipment corrosion, high activation temperature, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

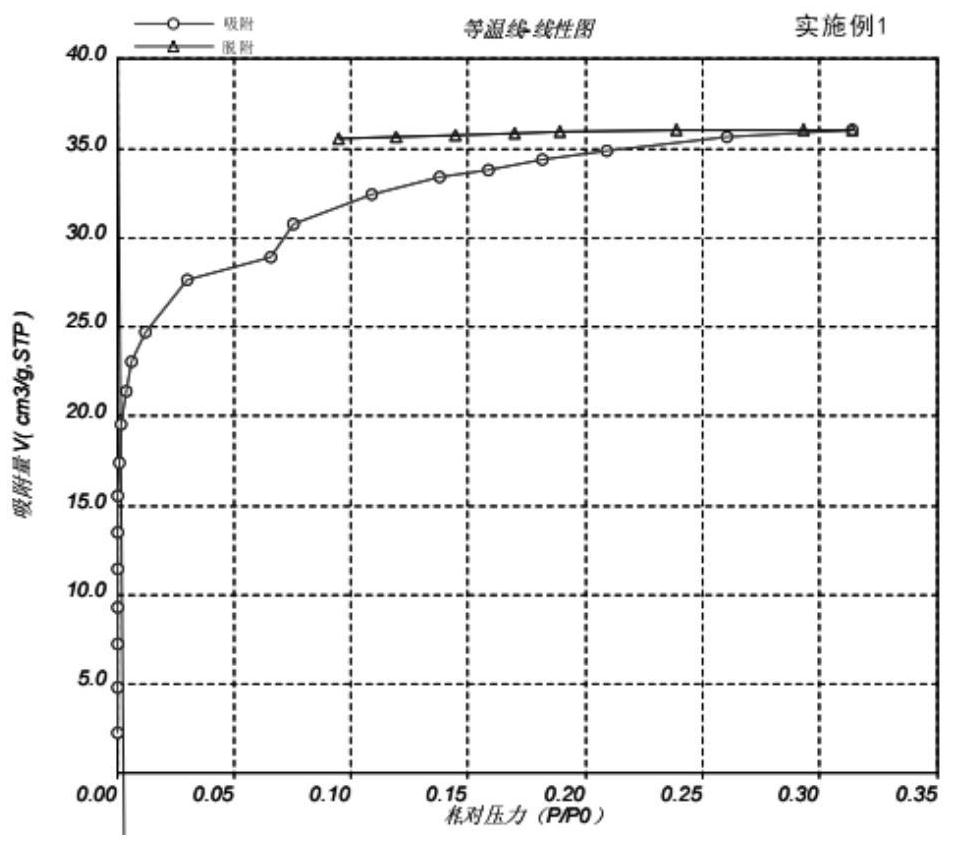

Embodiment 1

[0031] A method for preparing high-activity straw biochar, the preparation steps are as follows:

[0032] S1, take 2000g of wheat straw, put it in a cool and dark place to dry naturally, control the moisture content to less than 15%, pass it through a 20-mesh sieve after crushing, then add 20g of potassium pyrophosphate aqueous solution with a mass fraction of 60%, and add 100g of carboxymethyl Sodium cellulose to obtain straw mixture;

[0033] S2, putting the straw mixture obtained in S1 in a water bath at 80° C. for 1 hour, stirring it in a small mixer (YB05) for 1 hour, and then molding it in a molding machine with a pressure of 5 kPa to obtain activated wheat straw;

[0034] S3, the activated wheat straw obtained in S2 was placed in a pyrolysis furnace (BC10), the pyrolysis temperature was 350°C, the heating rate was 5°C / min, and the holding time was 2h. Take it out after cooling down to room temperature to obtain straw biochar with high activity.

Embodiment 2

[0036] A method for preparing high-activity straw biochar, the steps of which are basically the same as those in Example 1, the difference being that in S1, crushed wheat straw is passed through a 50-mesh sieve, and 100 g of potassium pyrophosphate aqueous solution with a mass fraction of 50% is added;

[0037] In S2, the water bath temperature is 85°C, the water bath time is 1.5h, the stirring time is 50min, and the molding machine pressure is 8kPa;

[0038] In S3, the pyrolysis temperature is 450°C, the heating rate is 3°C / min, and the holding time is 4h.

Embodiment 3

[0040] A method for preparing high-activity straw biochar, the steps of which are basically the same as in Example 1, the difference being that in S1, crushed wheat straw is passed through a 100-mesh sieve, and 200 g of potassium pyrophosphate aqueous solution with a mass fraction of 30% is added;

[0041] In S2, the water bath temperature is 90°C, the water bath time is 2h, the stirring time is 40min, and the molding machine pressure is 10kPa;

[0042] In S3, the pyrolysis temperature is 550°C, the heating rate is 5°C / min, and the holding time is 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com