Sucralose wastewater advanced treatment and desalination method

A sucralose and advanced treatment technology, which is applied in natural water treatment, water treatment parameter control, heating water/sewage treatment, etc., can solve problems such as increasing operating costs, affecting quality, and difficult to handle, so as to reduce operating costs, Effect of reducing environmental pressure and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

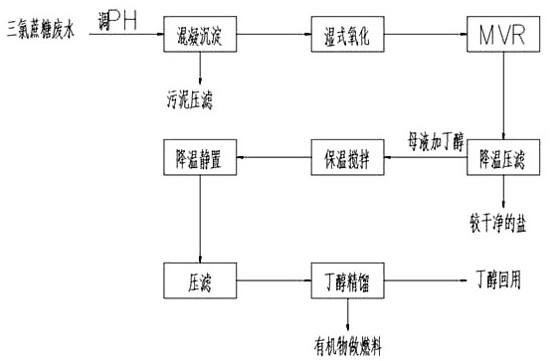

Method used

Image

Examples

Embodiment 1

[0030] (1) Obtain 20m³ of sucralose wastewater in the adjustment tank, and the measured COD is 85000mg / l, ammonia nitrogen is 22000, first use 20% ammonia water to adjust the pH of the wastewater to 6, and add a compound sedimentation agent with a mass fraction of 10% ( Hemei Environmental Protection Technology) solution 1m³; after stirring for 20 minutes, it settles, and the settling time is 2 hours. The colloid and suspended particles in the wastewater are removed by coagulation and sedimentation, and the supernatant is obtained. The COD of the supernatant is 72300, and the ammonia nitrogen value is 18500 ;

[0031] (2) Pump the supernatant into the wet oxidation equipment. The internal temperature of the oxidation tower is 200°C, the pressure is 2.3Mpa, and the residence time is 4 hours. -Dimethylformamide, the ammonia nitrogen in this solvent does not display, and the ammonia nitrogen content in the solvent can only be measured after the chain is broken by oxidation), the ...

Embodiment 2

[0034] The steps are the same as the above implementation case 1 (1) and (2);

[0035] (3) Add 1.5m³ recovered butanol to 1m³ mother liquor, stir at 60°C for 30min at a stirring rate of 200r / min, cool down to 35°C and let stand for 1h, obtain white crystal salt after pressure filtration, and measure ammonium chloride The content is 98.5%, the mother liquor is extracted and stratified to obtain 1.53m³ butanol, and the mother liquor 0.5m³ butanol is rectified in a rectification tower at a temperature of 65~80°C and a pressure of -0.9Mpa to obtain 1.45m³ of refined butanol with a purity of 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com