Alkaline tower wastewater treatment system and treatment method

A wastewater treatment system and wastewater treatment technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high discharge pressure, achieve increased salt content, wide applicability, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

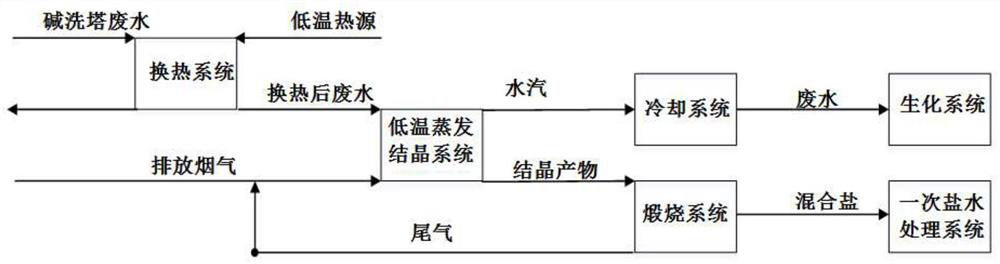

Method used

Image

Examples

Embodiment 1

[0035] A calcium carbide polyvinyl chloride enterprise uses a low-mercury catalyst to synthesize vinyl chloride monomer. The salt content of the alkali washing tower wastewater is about 20%, and the wastewater contains a large amount of organic matter and mercury. The CODcr content is above 2000mg / L, and the mercury in the wastewater The content is 0.1-1ppm. The alkali washing tower wastewater treatment system realizes the separation of salt, organic matter and mercury in the wastewater. The main components of the crystalline salt are sodium carbonate and sodium chloride after being calcined, which can be used to remove calcium ions in the primary brine process. After being treated by the biochemical system, the waste water can be reused to configure lye or other processes.

Embodiment 2

[0037] The waste water from the alkali washing tower of a coal-to-ethylene enterprise adopts this waste water treatment system after degreasing. The salt content of the waste water is about 15%, and the CODcr content of the waste water is above 10,000 mg / L. After low-temperature evaporation and crystallization, the separation of salt and organic matter is realized. , sell the crystalline salt to chlor-alkali enterprises, and the waste water will be reused after being treated by the biochemical system.

Embodiment example 3

[0039] An enterprise's high-salt organic wastewater adopts this wastewater treatment system, which realizes the separation of salt and organic matter in wastewater, and the cost of wastewater treatment is lower than that of MVR.

[0040] After heat exchange, the waste water from the alkali washing tower enters the low-temperature evaporation and crystallization equipment for countercurrent contact and mass transfer with the flue gas discharged from the thermal power plant. The waste water is continuously circulated to achieve evaporation and crystallization. Sodium is converted into sodium carbonate, and the mixed salt is reused in the primary brine treatment system. The evaporated water vapor contacts the cooling water for mass transfer and heat exchange, and the waste water is reused after being treated by the biochemical system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com