Method for preparing sintering-free cement by dry method and product thereof

A sintering-free, cement-free technology, applied in the field of traditional process technology innovation, can solve the problems of soil pollution, a large amount of waste liquid, high-strength dependence on physical and chemical properties, and limited promotion, and achieve excellent frost resistance and corrosion resistance, simple preparation process, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

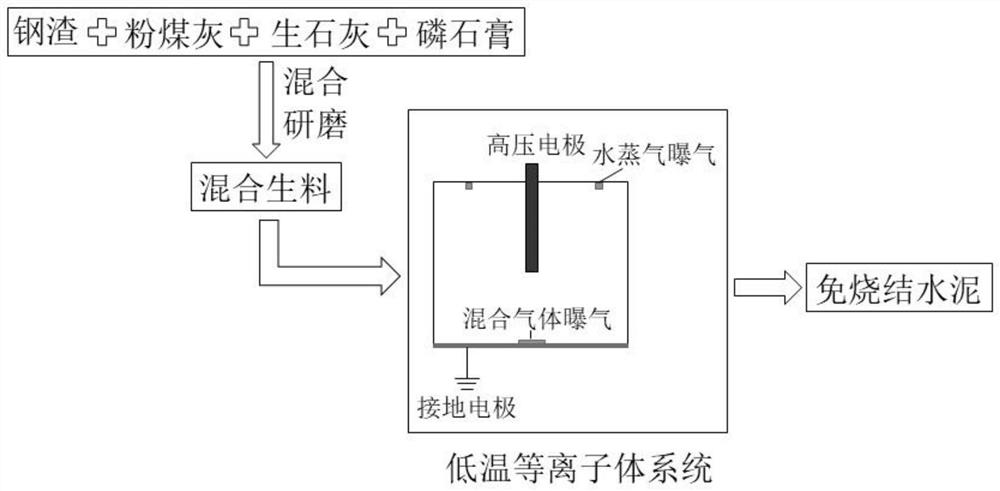

Method used

Image

Examples

Embodiment 1

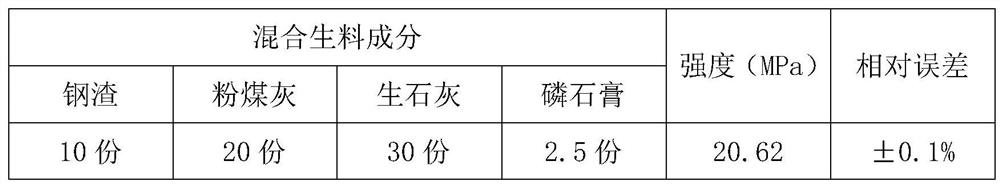

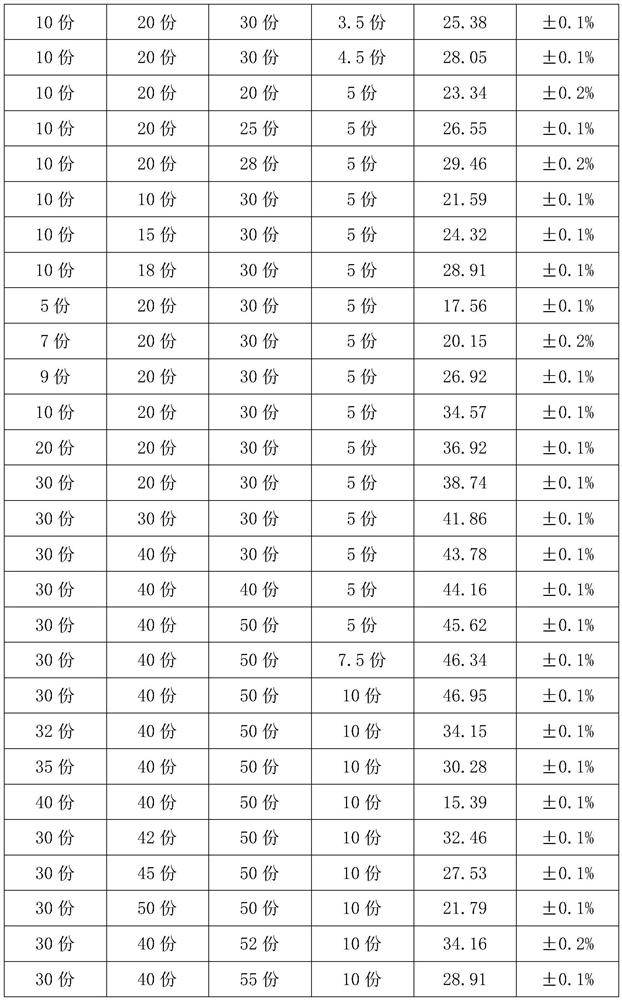

[0022] Example 1 Effect of Mixed Raw Meal Components on the Properties of the Prepared Non-sintering Cement

[0023] Preparation of sinter-free cement material: Weigh steel slag, fly ash, quicklime, and phosphogypsum according to the mass parts in Table 1, mix and grind for 3 hours to obtain mixed raw meal. Specifically, 5 parts, 7 parts, 9 parts, 10 parts, 20 parts, 30 parts, 32 parts, 35 parts and 40 parts of steel slag were weighed respectively in the mixed raw meal, and 10 parts and 15 parts of fly ash were weighed respectively. 20 parts, 18 parts, 20 parts, 30 parts, 40 parts, 42 parts, 45 parts, 50 parts, quicklime were weighed 20 parts, 25 parts, 28 parts, 30 parts, 40 parts, 50 parts, 52 parts, 55 parts 60 parts, 2.5 parts, 3.5 parts, 4.5 parts, 5 parts, 7.5 parts, 10 parts, 10.5 parts, 11.5 parts, 12.5 parts of phosphogypsum were weighed respectively. Put the mixed raw meal into the reactor of the low-temperature plasma system, irradiate it with low-temperature plasm...

Embodiment 2

[0030] Example 2 Influence of low-temperature plasma action time on the performance of prepared non-sintering cement

[0031] Preparation of sinter-free cement material: Weigh 30 parts of steel slag, 40 parts of fly ash, 50 parts of quicklime, and 10 parts of phosphogypsum according to the parts by mass, mix and grind for 7.5 hours to obtain mixed raw meal. Put the mixed raw material into the reactor of the low-temperature plasma system, and irradiate the low-temperature plasma for 0.25 hours, 0.35 hours, 0.45 hours, 0.5 hours, 1 hour, 1.5 hours, 1.55 hours, 1.65 hours, and 1.75 hours, and take out the mixture , dried at 100°C and ground for 3 hours to avoid sintering cement materials, wherein during the low-temperature plasma irradiation process, the mixed gas of sulfur dioxide and oxygen is exposed to the reactor from the ground electrode (low-voltage electrode) end of the low-temperature plasma system , Expose water vapor from the high-voltage electrode end of the low-tempe...

Embodiment 3

[0036] Example 3 The influence of sulfur dioxide and oxygen volume ratio on the performance of prepared non-sintering cement

[0037] Preparation of non-sintering cement material: Weigh 30 parts of steel slag, 40 parts of fly ash, 50 parts of quicklime, and 10 parts of phosphogypsum according to the parts by mass, mix and grind for 12 hours to obtain mixed raw meal. Put the mixed raw material into the low-temperature plasma reactor, irradiate the low-temperature plasma for 1.5 hours, take out the mixed material, dry it at 150°C, and grind it for 4 hours to avoid sintering cement materials. The ground electrode (low-voltage electrode) end of the plasma system is exposed to sulfur dioxide and oxygen mixed gas into the reactor, and water vapor is exposed to the reactor from the high-voltage electrode end of the low-temperature plasma system. The volume ratio of sulfur dioxide and oxygen is 1: 100, 1.5: 100, 1.8: 100, 2: 100, 4: 100, 6: 100, 6.5: 100, 7: 100, 8: 100, the humidity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com