Carboxymethyl chitosan-nano magnesium oxide composite membrane material and preparation method thereof

A technology of carboxymethyl chitosan and nano-magnesium oxide, applied in flexible coverings, packaging, wrapping paper, etc., can solve the problems of affecting economic benefits, less research, and long time for film preparation, and achieve broad application prospects , prolong shelf life and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

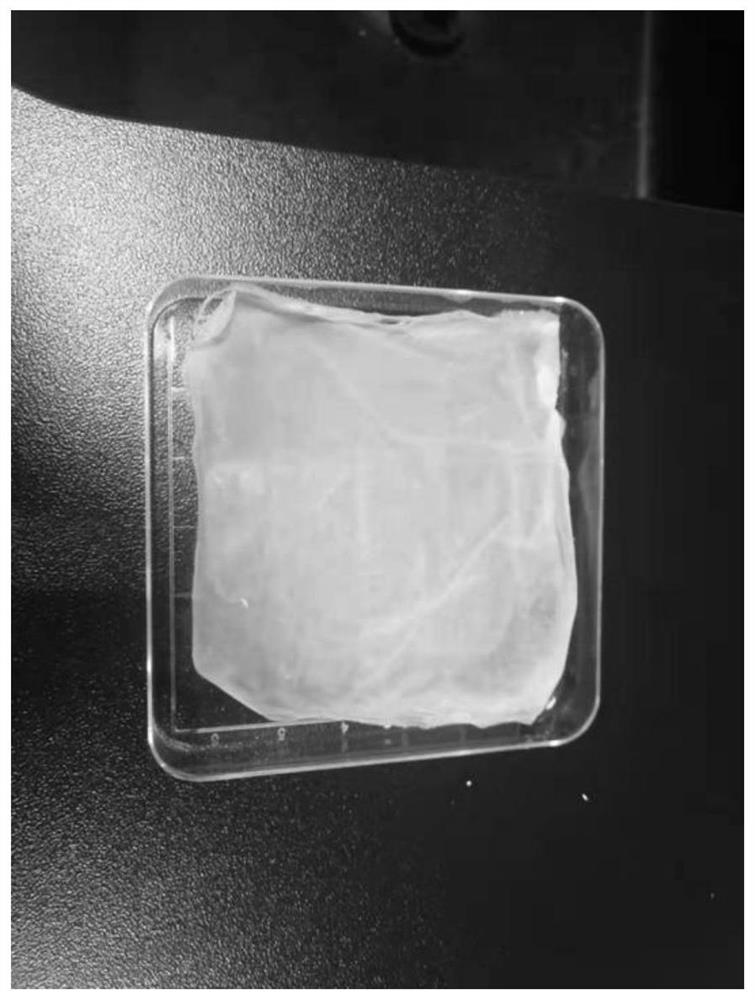

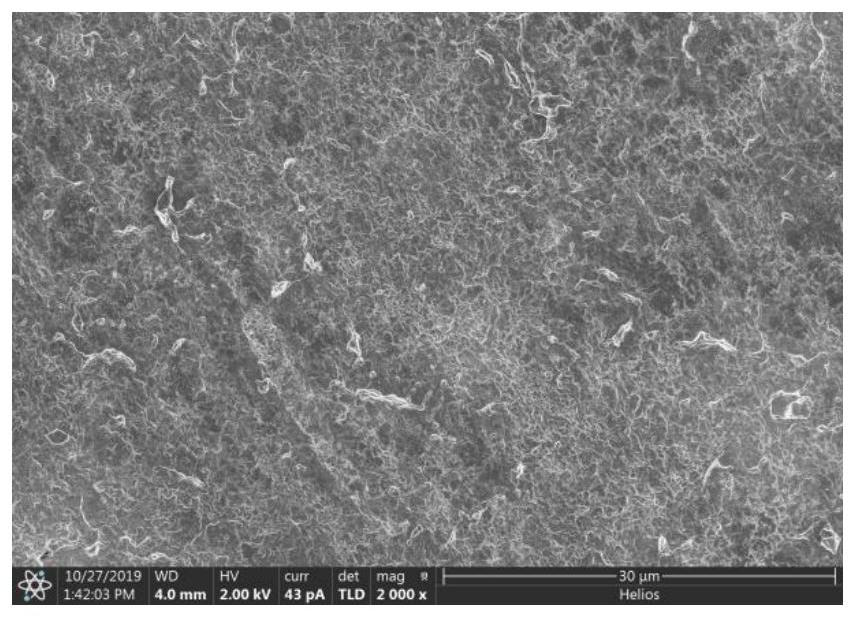

[0030] For new food packaging materials, this example proposes a rapid preparation method of carboxymethyl chitosan-nano-magnesium oxide composite film. After dissolving carboxymethyl chitosan with magnetic stirring and obtaining a clarified dissolved product, add carboxymethyl chitosan Glycerin with 50-60% chitosan mass is mixed with different weights of nano-magnesia powder and ultrasonically obtained to obtain a film solution; spread it on a plastic plate and put it in an oven and dry it to form a film; then perform characterization and performance Determination. The carboxymethyl chitosan-nanometer magnesia composite film material that present embodiment makes has good physical and chemical properties (it has better and stable film-forming property at room temperature, possesses certain plasticity and elasticity), and preparation is simple and fast, and Compared with chitosan-metal oxide composite film, 18 hours of preparation time can be saved (see Figure 10 ), and has ...

Embodiment 2

[0044] refer to Figure 1-9 For illustration, this embodiment provides a kind of actual preparation carboxymethyl chitosan-nanometer magnesium oxide composite membrane material, comprises following actual preparation steps,

[0045] S1, the carboxymethyl chitosan powder that 0.5g weight-average molecular weight is 600,000 is dissolved in the 50mL aqueous solution, obtains the carboxymethyl chitosan solution that concentration is 10g / L;

[0046] S2, adding 0.25g of glycerol to the carboxymethyl chitosan solution obtained in step S1, and stirring to obtain a mixed solution;

[0047] S3. Slowly add 0.5 g of nano-magnesium oxide to the mixed solution in step S2 under stirring, and stir evenly to obtain a carboxymethyl chitosan-nano-magnesia mixed solution;

[0048] S4, cooling and drying the carboxymethyl chitosan-nanometer magnesium oxide mixture obtained in step S3 at a temperature of 60° C. for 24 hours to obtain a carboxymethyl chitosan-nanometer magnesium oxide composite mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com