Polyimide carbon fiber containing ultramicro pores and preparation method and application thereof

A polyimide-based carbon fiber, polyimide fiber technology, applied in separation methods, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of complex operation, undisclosed carbon dioxide adsorption capacity, etc., and simplify the preparation process. , The effect of shortening the production cycle and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present invention uses embodiment 1 as a comparative example. The domestic Yilun fiber was placed in a heat treatment furnace and treated in a nitrogen atmosphere at 800°C for 60 minutes to obtain polyimide-based carbon fiber 1 containing ultra-micropores.

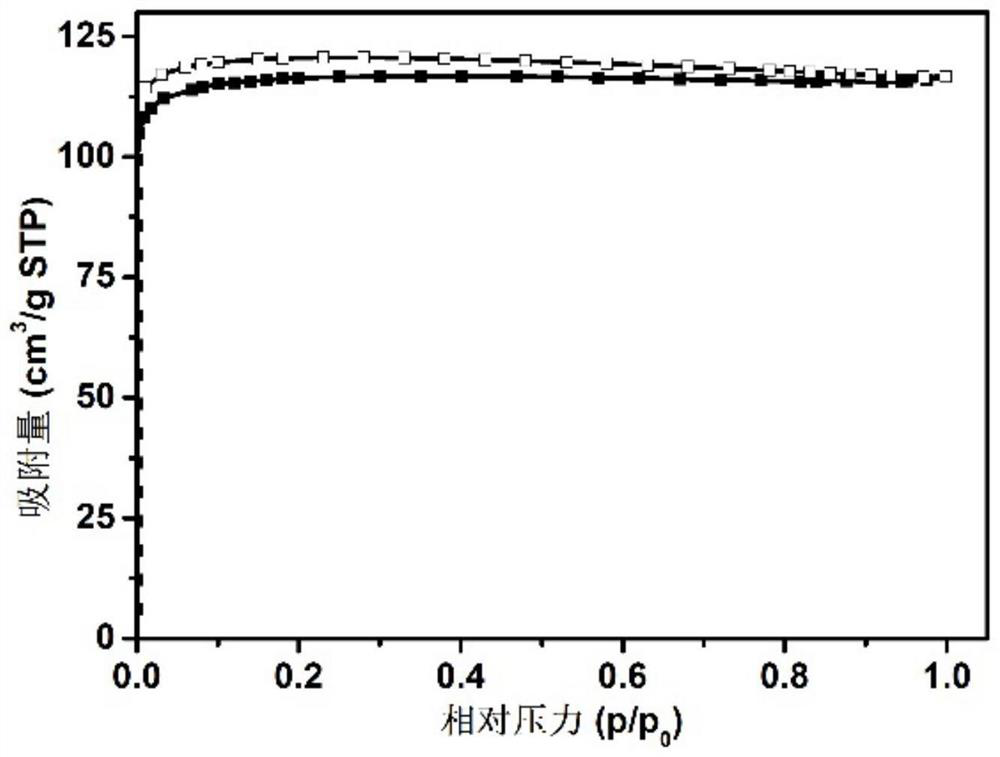

[0054] The nitrogen isothermal adsorption-desorption curve measured at -196°C for the polyimide-based carbon fiber 1 containing ultramicropores is as follows: figure 1 As shown, according to the IUPAC classification, it can be known that the nitrogen isothermal adsorption-desorption curve conforms to type I, and contains a smaller hysteresis loop, indicating that the pores of the polyimide-based carbon fiber 1 containing ultramicropores are mostly micropores, and there are a small amount of micropores. of mesopores.

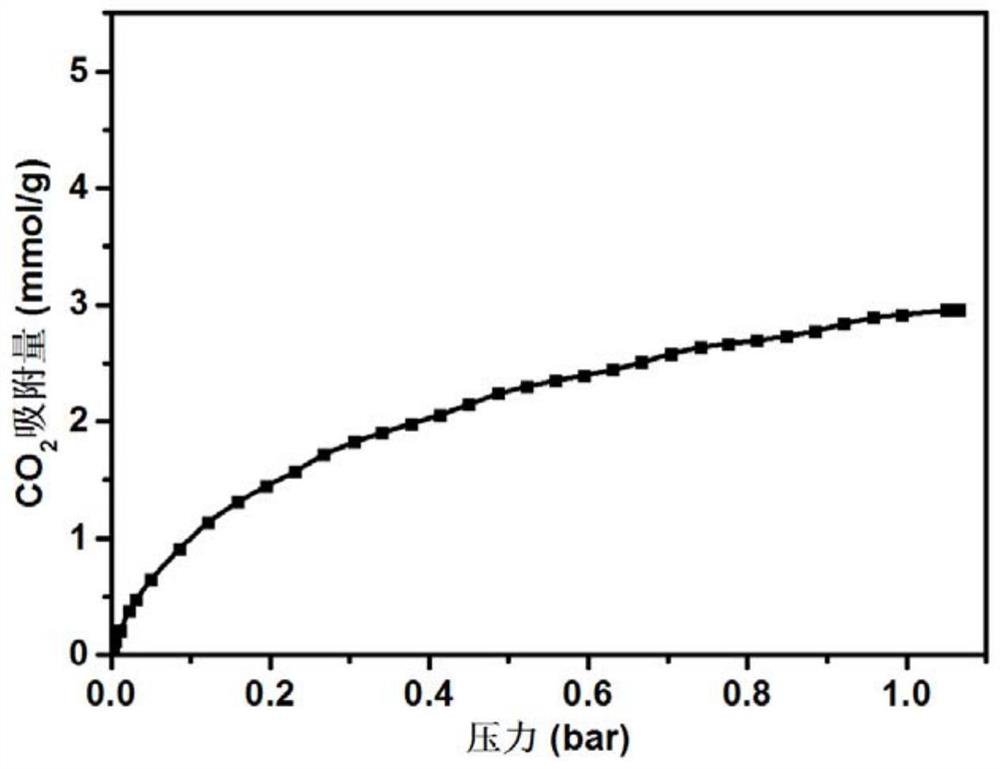

[0055] The specific surface area of polyimide-based carbon fiber 1 containing ultramicropores is 448m 2 / g, the micropore volume is 0.143cm 3 / g, ultramicropore volume is 0.131g / cm 3 , The ni...

Embodiment 2

[0058] The mass ratio of potassium carbonate to domestic Yilun fiber is 2, the polyimide fiber is put into a 4% potassium carbonate aqueous solution, mixed and stirred, taken out and dried, and treated at 800°C for 60 minutes in a nitrogen atmosphere to obtain a polyimide fiber containing Ultramicroporous polyimide-based carbon fibers2.

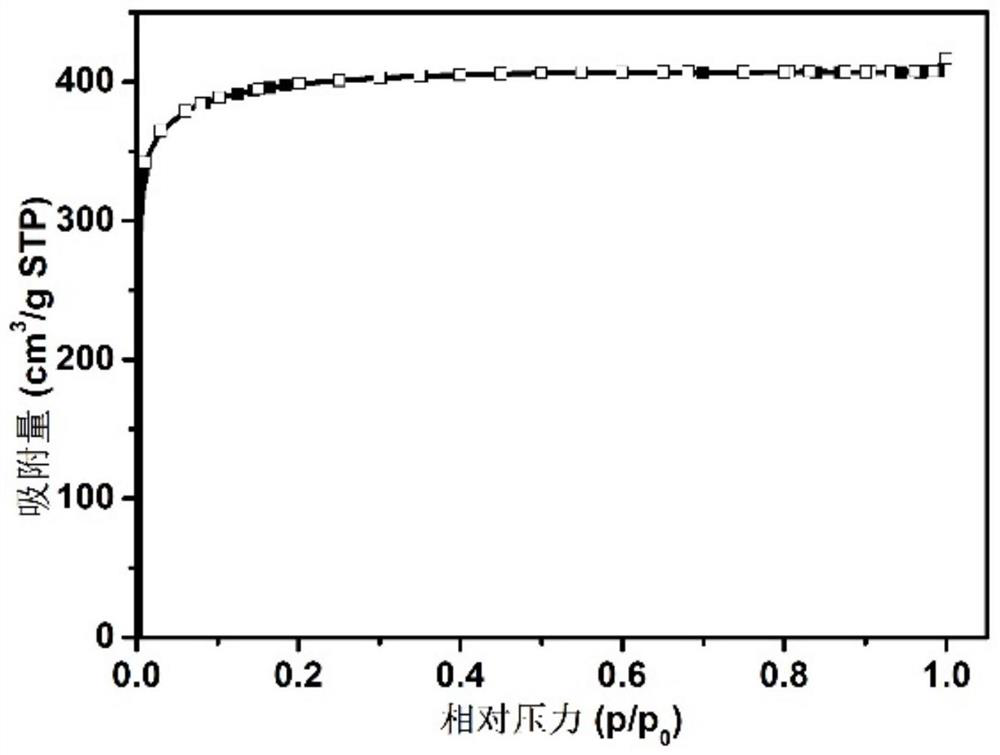

[0059] The nitrogen isothermal adsorption-desorption curve measured at -196°C for the polyimide-based carbon fiber 2 containing ultramicropores is as follows: image 3 As shown, according to the IUPAC classification, it can be known that the nitrogen isothermal adsorption-desorption curve conforms to type I, and no obvious hysteresis loop is observed, indicating that the polyimide-based carbon fiber 2 containing ultramicropores is mainly micropores, and the micropores The pore size distribution range is relatively wide, and it also has narrow mesopores. The specific surface area of polyimide-based carbon fiber 2 containing ultramicropores ...

Embodiment 3

[0063] The mass ratio of zinc chloride to domestic Yilun fiber is 2, the polyimide fiber is put into a zinc chloride aqueous solution with a concentration of 4%, mixed and stirred, taken out and dried, and treated at 800°C in a nitrogen atmosphere for 60 minutes, A polyimide-based carbon fiber 3 containing ultramicropores was obtained.

[0064] The nitrogen isothermal adsorption-desorption curve measured at -196°C for the polyimide-based carbon fiber 3 containing ultramicropores is as follows: Figure 6 As shown, according to the IUPAC classification, it can be seen that the nitrogen isotherm adsorption-desorption curve conforms to type I, and no obvious hysteresis loop is observed, indicating that the polyimide-based carbon fiber 3 containing ultramicropores is mainly micropores. Polyimide-based carbon fiber 3 containing ultra-micropores, with a specific surface area of 792m 2 / g, the micropore volume is 0.302cm 3 / g, ultramicropore volume is 0.188g / cm 3 , The nitrogen c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com