Preparation method of polymer microspheres with uniform particle size

A polymer microsphere and particle size technology, which is applied in the field of preparation of uniform particle size polymer microspheres, can solve the problems of limited popularization, integration, instability, etc., achieve rapid swelling of polymerized monomers, reduce production costs, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

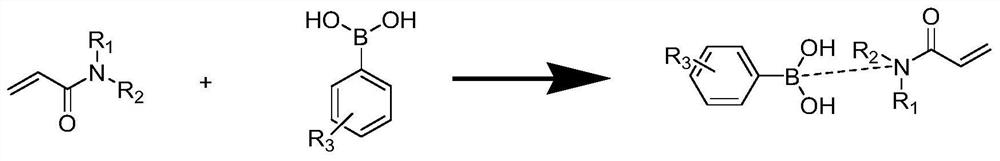

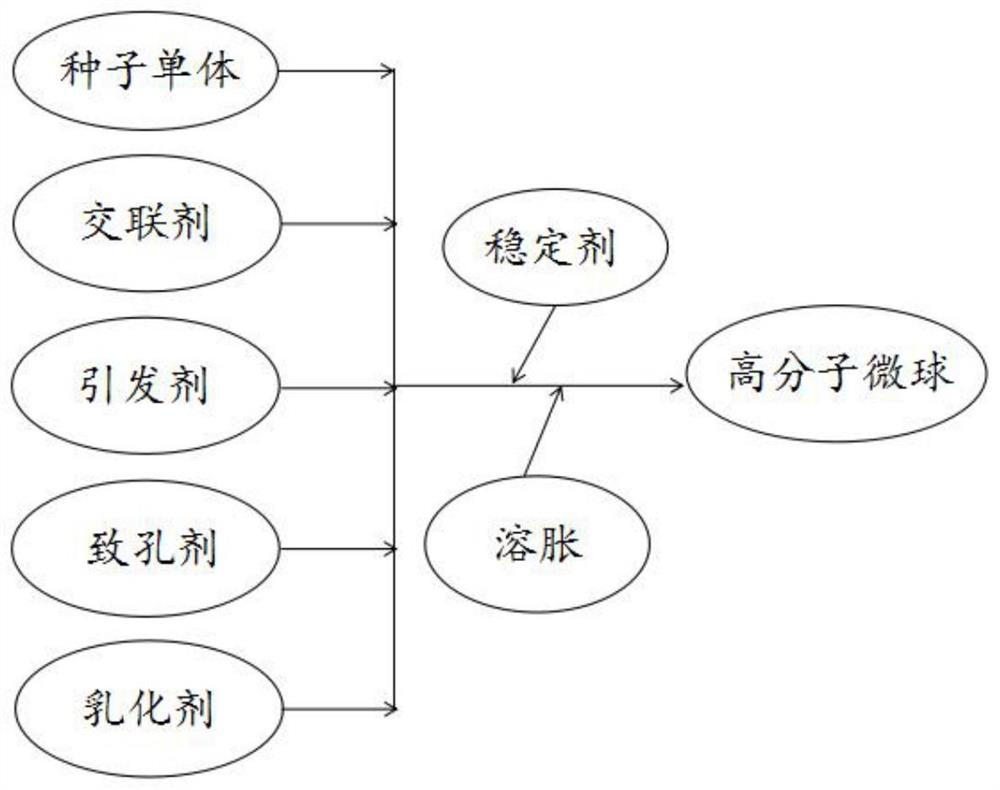

[0032] Such as Figure 1-6 , a method for preparing polymer microspheres with uniform particle size, comprising the following steps:

[0033] (1) Preparation of swelling monomer: take equimolar equivalents of acrylamide and phenylboronic acid,

[0034] The reaction is carried out under the condition of water phase or in the presence of an emulsifier to obtain an aqueous solution of a new compound formed by coordination of the acrylamide substance and the phenylboronic acid substance, and the water solubility of the aqueous solution of the new compound is greater than 2g / 100mL.

[0035] (2) Preparation of activated seed microspheres: Add the new compound in step (1) to the seed, after swelling at room temperature, select potassium persulfate or sodium bisulfite redox initiation system, and initiate the new compound in the seed at room temperature. Polymerize to obtain activated seed microspheres with uniform particle size, and set aside.

[0036] (3) Preparation of oil phase:...

Embodiment 1

[0050] Preparation of seed microspheres

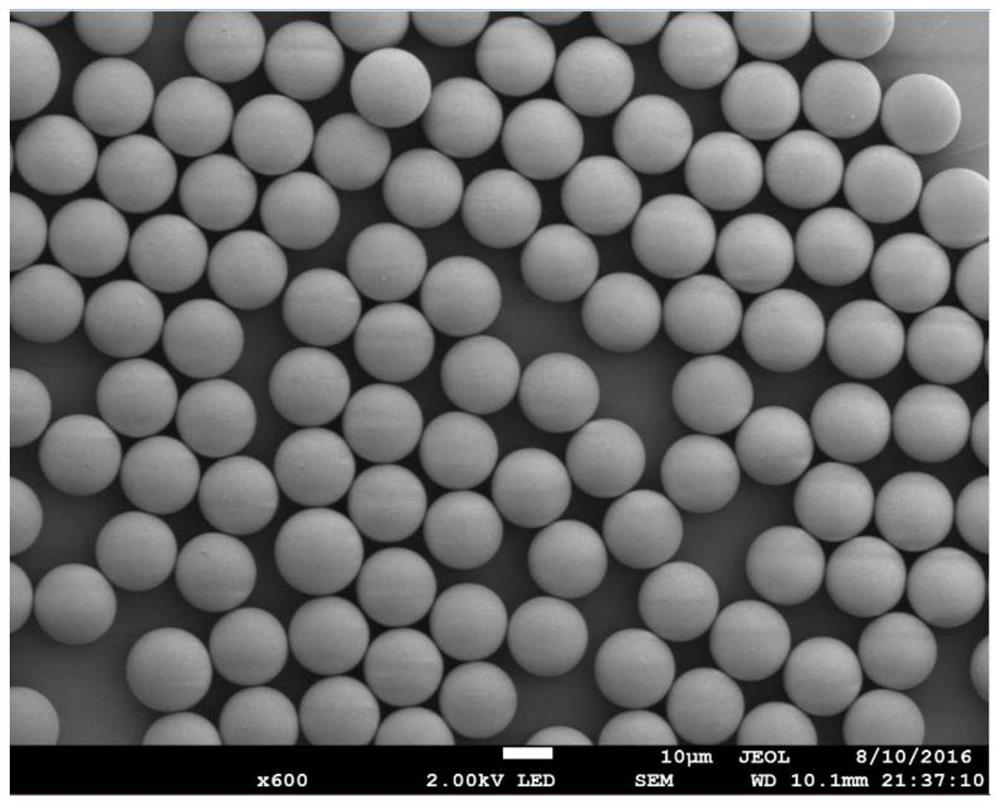

[0051] Take 1.2 g of polyvinylpyrrolidone (PVP) and dissolve it in a mixture of 90 mL of ethanol and 10 mL of deionized water, add it to a 250 mL three-necked flask with a reflux condenser, and add 0.4 g of azobis A solution of 25 g of isobutyronitrile (AIBN) in styrene was polymerized at 70 °C for 8 h; the product was centrifuged at a speed of 4 000 r / m, the supernatant liquid was decanted, washed with absolute ethanol, and washed with 0.25% decathene Dialkyl sodium sulfate solution replaces ethanol, and is made into 0.25% sodium lauryl sulfate solution of 5% solid content, obtains the polystyrene microsphere primary seed that particle size is 2.5 microns, CV value 2.1%.

Embodiment 2

[0053] Preparation of seed microspheres

[0054] Dissolve 0.265g of sodium chloride (NaCl) in 500g of distilled water, then add 45g of monomeric styrene (St) into the three-necked flask, blow nitrogen to drive oxygen for 15 minutes under stirring at 350rpm, then raise the temperature to 70°C, and reach temperature equilibrium , add 5g of 10% potassium persulfate KPS aqueous solution, and start polymerization; under the protection of nitrogen, the polymerization time is 24 hours, after the reaction is completed, cool to room temperature, and obtain the primary seeds of polystyrene microspheres with a particle size of 580nm and a CV value of 2.3%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com