Laser 3D-printing silicon carbide ceramic-aluminum composite material and preparation method thereof

A technology for printing silicon carbide ceramics and aluminum composite materials, which is applied in the direction of additive processing, metal processing equipment, transportation and packaging, etc. Uniformity and stability, avoiding pore defects, and improving the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

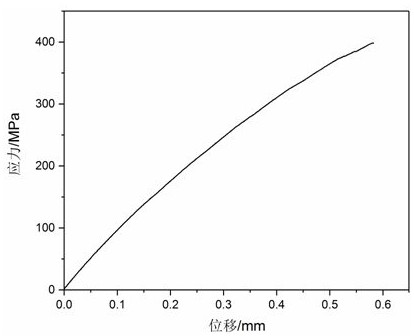

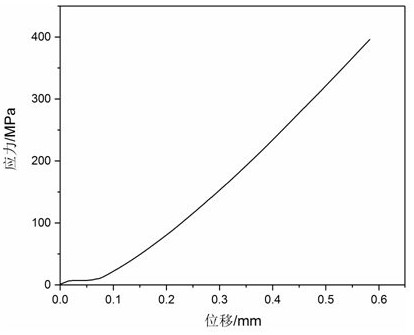

Image

Examples

Embodiment

[0020] A laser 3D printing silicon carbide ceramic aluminum composite material, which is composed of silicon carbide particles, binder, and aluminum alloy matrix, wherein the volume fraction of silicon carbide particles is 60%, the volume fraction of binder is 5%, and the volume fraction of aluminum alloy matrix It is 35%; it is characterized in that the silicon carbide particles and the binder are printed into a silicon carbide porous ceramic preform by laser 3D, and the aluminum alloy is filled in the silicon carbide porous ceramic preform; the particle size of the silicon carbide particles is 25 μm; the Described binder is aluminum powder, and aluminum powder particle size is 20 μ m; A kind of preparation method of laser 3D printing silicon carbide ceramic aluminum composite material is characterized in that comprising the steps of following order:

[0021] (1) Mix the silicon carbide particles and the binder evenly, put them into the laser 3D printing powder bed, and use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com