Preparation method of graphene-modified polyethylene terephthalate (PET) blend fiber

A graphene modified and blended fiber technology, which is applied in the field of chemical fibers, can solve the problems of poor dispersion and achieve high oil absorption, high impact resistance, and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

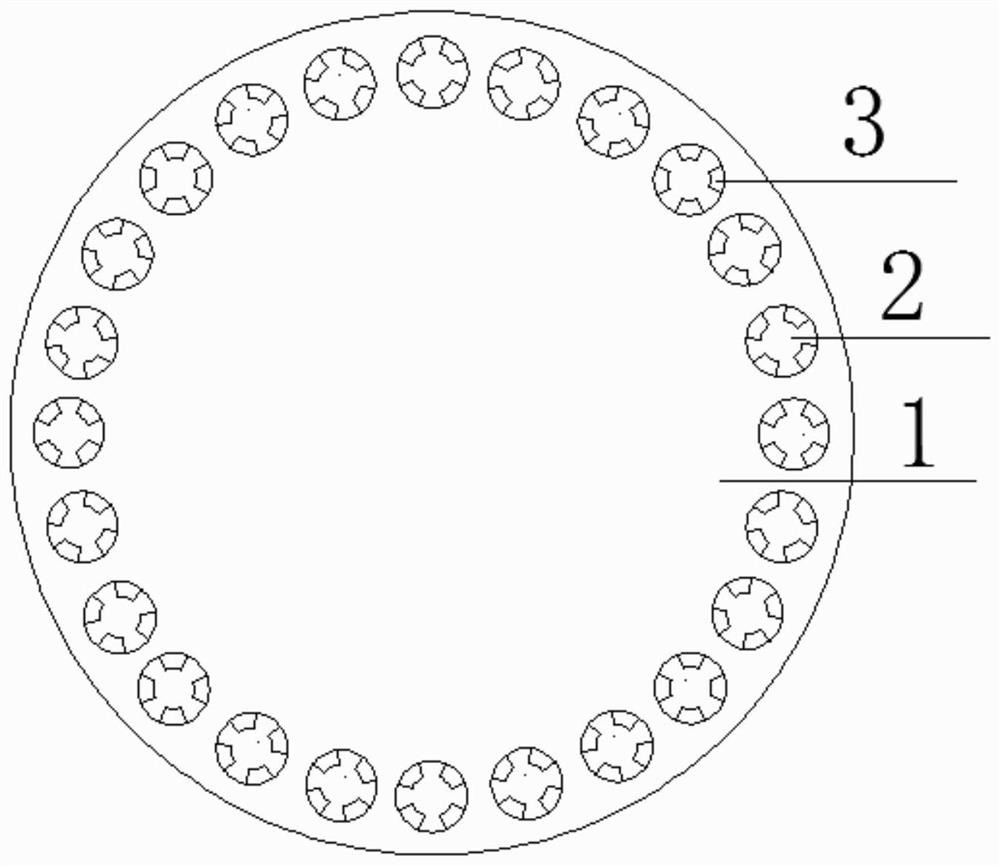

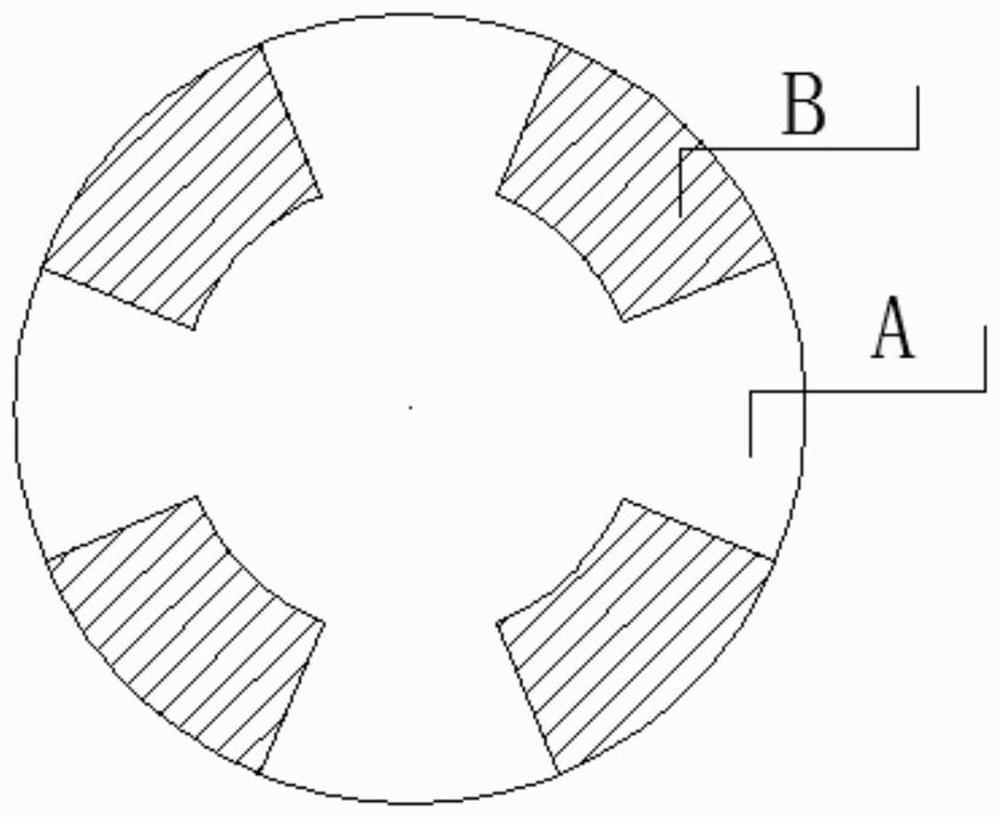

[0038] A kind of preparation method of graphene modified PET blended fiber, comprises the following steps:

[0039] 1) Preparation of modified graphene: Add graphite and sodium nitrate to a round bottom flask under ice bath conditions, pour concentrated sulfur and stir to form a paste, slowly add potassium permanganate, control the temperature not to exceed 20°C, and stir for 1.5 -2h. Then the temperature was raised to 35-40°C and kept for 2-2.5h. Add distilled water dropwise and raise the temperature to 98-100°C, at which time a golden yellow suspension appears. Add hydrogen peroxide while hot, pour into distilled water, and ultrasonically disperse for 1-1.2h to obtain a graphene oxide mixture. Slowly add the cationic modifier DMSO and / or tributylphosphine containing long carbon chains to the above mixture, and stir for 10- After 15 minutes, a reddish-brown precipitate was obtained, separated by centrifugation, washed alternately with hydrochloric acid solution and distille...

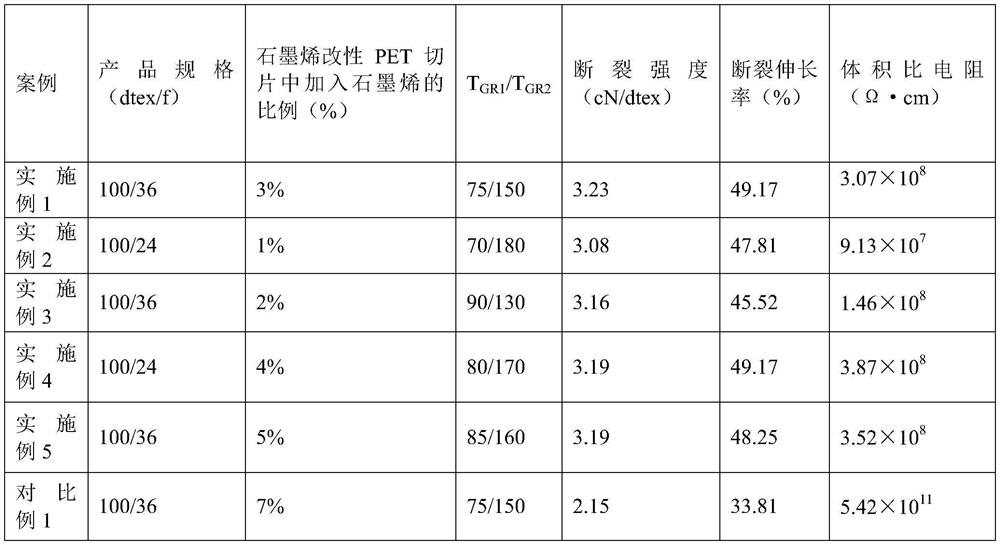

Embodiment 1

[0046] A kind of preparation method of graphene modified PET blended fiber, comprises the following steps:

[0047] 1) Preparation of modified graphene: Add graphite and sodium nitrate to a round bottom flask under ice bath conditions, pour concentrated sulfur into it and stir to form a paste, slowly add potassium permanganate, control the temperature at 15°C, and stir for 1.8h . Then the temperature was raised to 37°C and kept for 2.3h. Distilled water was added dropwise, and the temperature was raised to 99°C, at which point a golden yellow suspension appeared. Add hydrogen peroxide while hot, pour into distilled water, and ultrasonically disperse for 1.1 hours to obtain a graphene oxide mixture. Slowly add the cationic modifier DMSO and / or tributylphosphine containing long carbon chains to the above mixture, and stir for 12 minutes to obtain a reddish-brown color The precipitate was separated by centrifugation, washed alternately with hydrochloric acid solution and distil...

Embodiment 2

[0054] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0055] A kind of preparation method of graphene modified PET blended fiber, comprises the following steps:

[0056] 1) Preparation of modified graphene: Add graphite and sodium nitrate to a round bottom flask under ice bath conditions, pour concentrated sulfur and stir to form a paste, slowly add potassium permanganate, control the temperature not to exceed 20°C, and stir for 1.5 -2h. Then the temperature was raised to 35-40°C and kept for 2-2.5h. Add distilled water dropwise and raise the temperature to 98-100°C, at which time a golden yellow suspension appears. Add hydrogen peroxide while hot, pour into distilled water, and ultrasonically disperse for 1-1.2h to obtain a graphene oxide mixture. Slowly add the cationic modifier DMSO and / or tributylphosphine containing long carbon chains to the above mixture, and stir for 10- After 15 minutes, a reddish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com