Construction method of liquid crystal confinement space assembly microarray and liquid crystal composite material prepared by same

A construction method and a technology of composite materials, which are applied in the field of realization of liquid crystal-induced self-assembly arrays and regulation of assembly structures, can solve problems such as technology exploration that has not yet appeared and technology is limited, and achieve a wide range of cellulose sources, simple and feasible processes, and biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

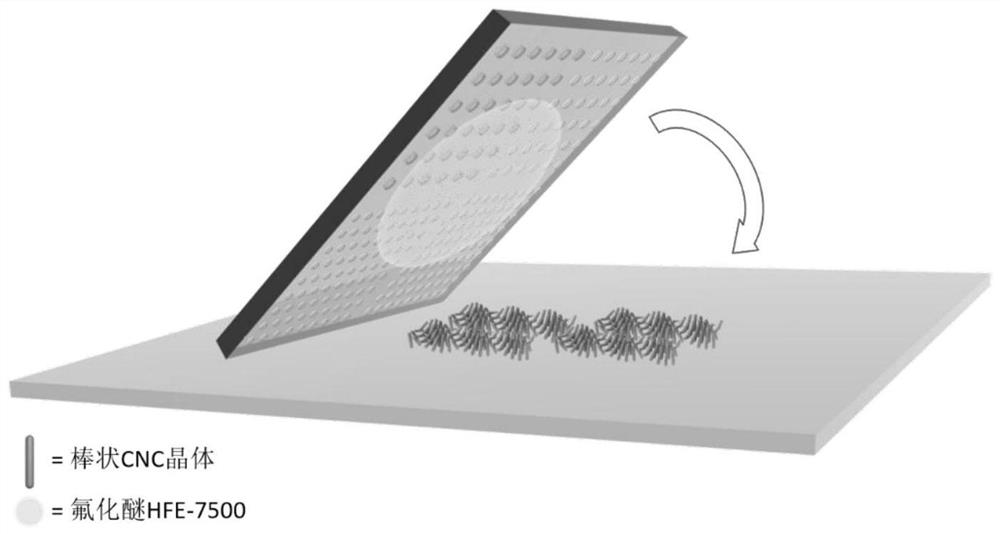

[0040] In this embodiment, the filling and self-assembly steps of the cellulose nanocrystal liquid crystal suspension or the mixed suspension of cellulose nanocrystal liquid crystal and dopant molecules in the microcavity array are as follows:

[0041] The fluorinated ether adopts the fluorinated ether HFE-7500 produced by 3M Company, and the completed silicone rubber with the microcavity array is placed on a glass slide A facing up; the fluorinated ether HFE-7500 (0.05 mL / cm 2 ) coated on the surface of the chip, spread evenly. Take the solution to be assembled, drop 10 μL of this part of the suspension with a concentration of about 8wt% on another glass slide B, and apply it evenly in a small area; peel off the silicone rubber from the glass slide A, face down quickly Cover the glass slide B coated with the suspension to be assembled, squeeze out excess air bubbles and liquid crystals, wait for the assembly to complete, and obtain a liquid crystal composite material with an...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this embodiment, the pitch of the liquid crystal assembly is affected by the microcavity structure, and the method steps are as follows:

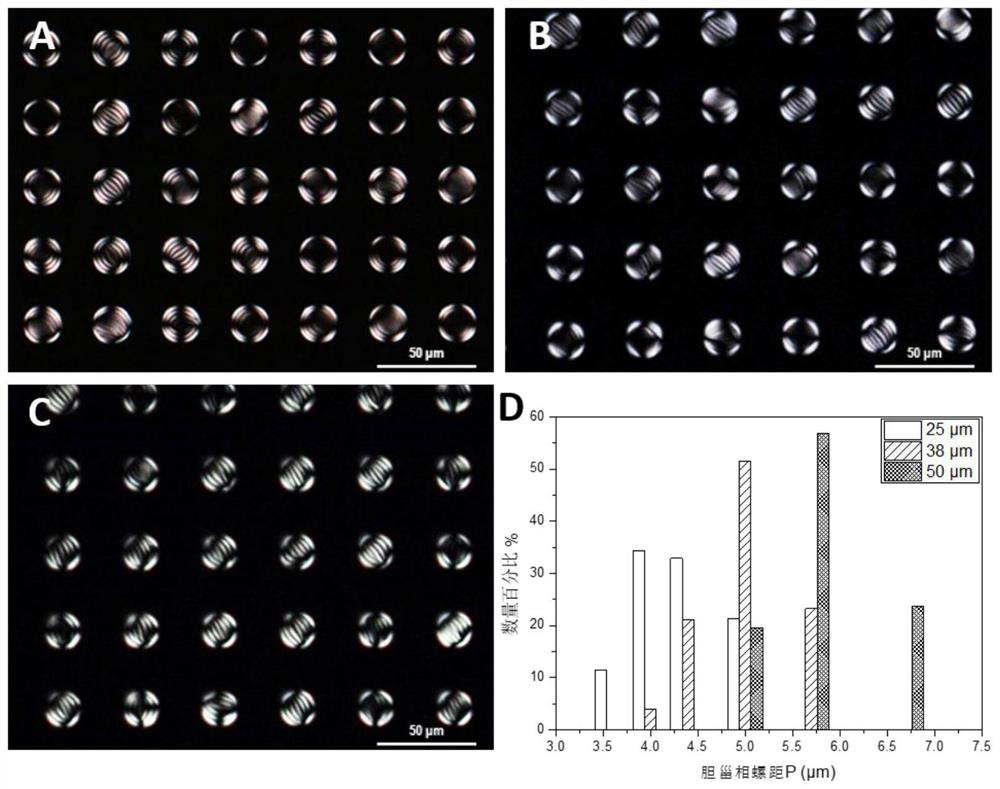

[0045] Changing the size of the cylindrical microcavity array, setting the diameter range from 10 μm to 50 μm, and the height range from 10 μm to 50 μm, can effectively adjust the structure and arrangement of the liquid crystal assembly, which is manifested as a change in the pitch of the assembly. If the height of the microcavity array is increased and the diameter remains unchanged, the pitch of the assembly will increase. The experimental operation is shown in Example 1, and the specific schematic diagram is shown in image 3 shown. image 3 It is the self-assembly image of the cellulose nanocrystal liquid crystal in this example and the numerical statistical distribution diagram of the cholesteric phase pitch P formed by the self-assembly of t...

Embodiment 3

[0047] This embodiment is basically the same as the previous embodiment, and the special features are:

[0048] In this embodiment, the pitch of the liquid crystal assembly is affected by adding PEGDA-575 molecules, and the method steps are as follows:

[0049] Adding PEGDA-575 to the cellulose nano-liquid crystal system forms a blend system to increase the helical pitch of liquid crystal assembly. Evaporate and concentrate the cellulose nanocrystalline liquid crystal to 8wt%, take 1mL and place it in a small bottle, pipette 110μL of PEGDA-575 into the liquid crystal, oscillate fully on the oscillator and place it on the shaker overnight to obtain CNC The mixed system with PEGDA-575, the experimental operation is as described in Example 3, and the specific schematic diagram is as follows Figure 4 shown. Figure 4 It is the self-assembly image of the cellulose nanocrystal liquid crystal in the blend system and the numerical statistical distribution map of the cholesteric pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com