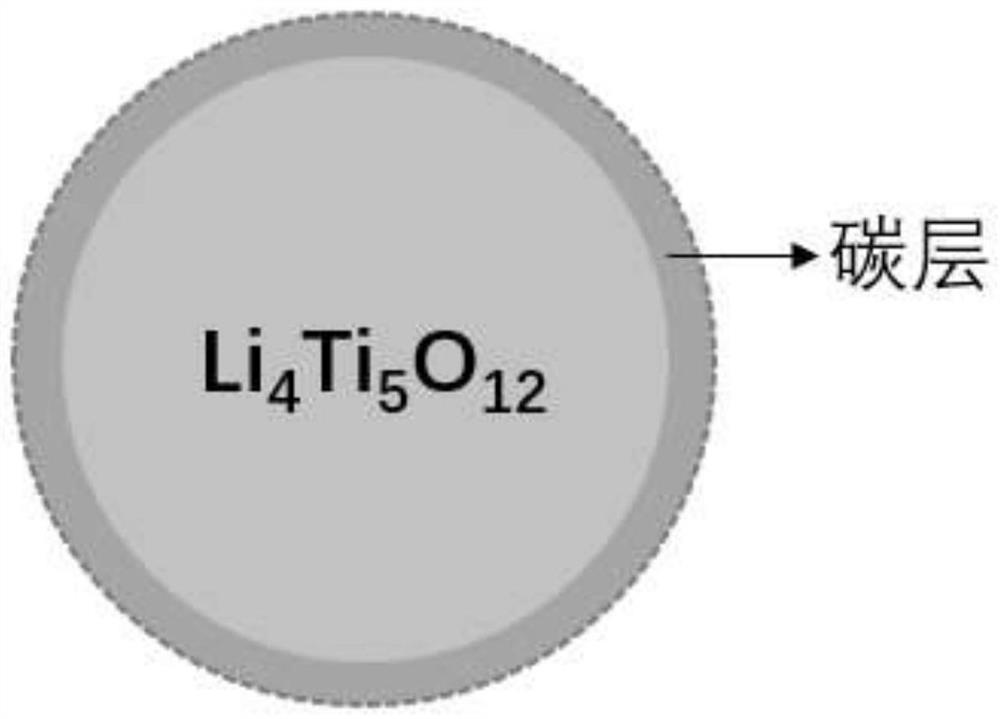

Preparation method of carbon-coated lithium titanate negative electrode material

A technology for carbon-coated lithium titanate and negative electrode materials, which is applied to battery electrodes, electrical components, electrochemical generators, etc. Cumbersome and other problems, to achieve the effect of being conducive to large-scale industrial production, eliminating the need for hydrothermal reactions, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

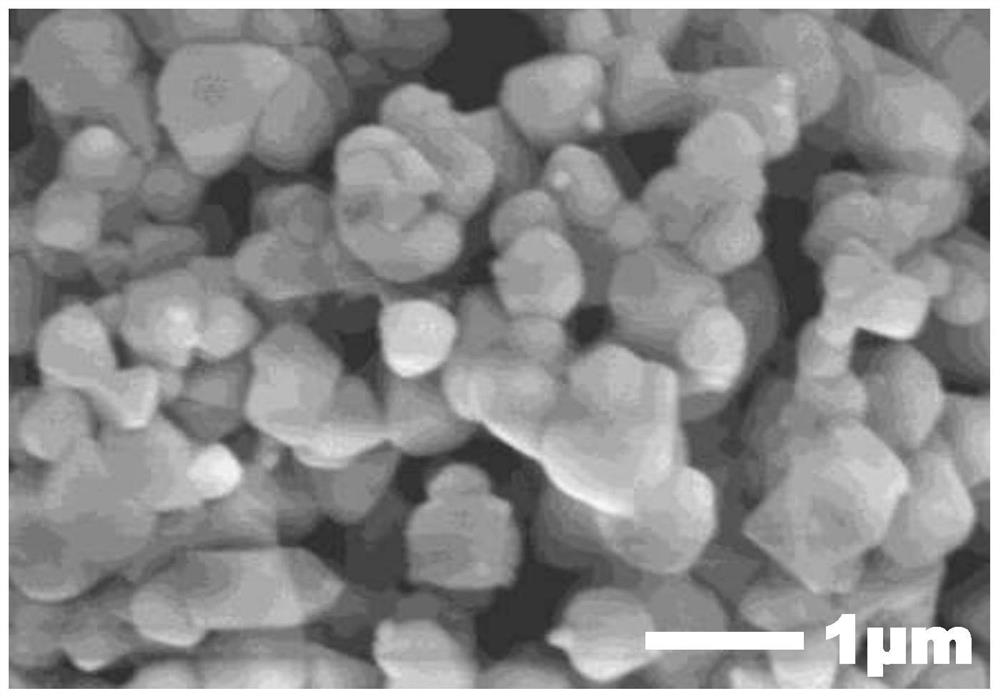

[0028] A method for preparing a carbon-coated lithium titanate negative electrode material provided by the invention comprises the following steps:

[0029] (1) Add 1000g of titanium dioxide nanoparticles into 2500mL of tannic acid aqueous solution with a concentration of 0.01mol / L, ultrasonically disperse for 30min, and stir at room temperature for 1h;

[0030] (2) vacuum filter the solution in step (1), and dry the filter cake in an oven at 100°C for 24 hours to obtain compound A;

[0031] (3) Compound A and 379g lithium carbonate are added into a high-speed mixer, the high-speed mixer spindle speed is 1000r / min, and the working time is 5min to obtain compound B;

[0032] (4) The composite B was placed in a tube furnace and calcined at 800° C. for 8 hours in an inert atmosphere to obtain a carbon-coated lithium titanate negative electrode material.

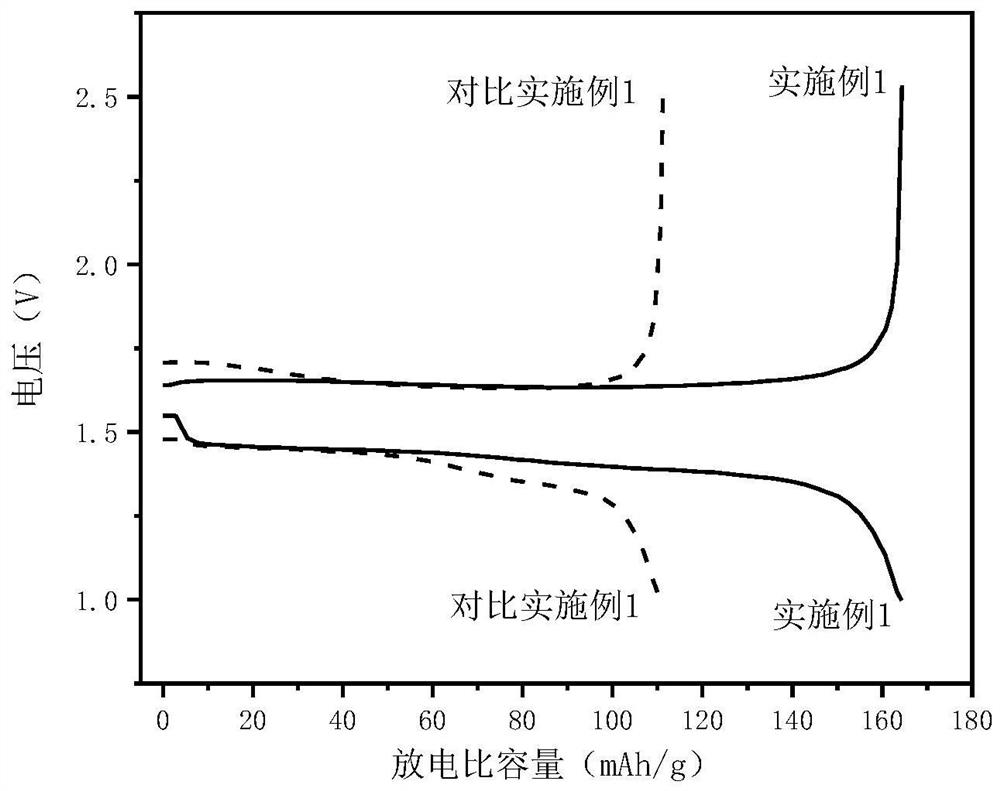

[0033] The battery performance test was carried out on the carbon-coated lithium titanate negative electrode material prepare...

Embodiment 2

[0035] A method for preparing a carbon-coated lithium titanate negative electrode material provided by the invention comprises the following steps:

[0036] (1) Add 1000g of titanium dioxide nanoparticles into 2500mL of 0.02mol / L tannic acid aqueous solution, ultrasonically disperse for 30min, and stir at room temperature for 2h;

[0037] (2) vacuum filter the solution in step (1), and dry the filter cake in an oven at 80°C for 40 hours to obtain compound A;

[0038] (3) Compound A and 250g lithium hydroxide were added into a high-speed mixer, the spindle speed of the high-speed mixer was 750r / min, and the working time was 8min to obtain compound B;

[0039] (4) The composite B was placed in a tube furnace and calcined at 850° C. for 7 hours in an inert atmosphere to obtain a carbon-coated lithium titanate negative electrode material.

[0040] The battery performance test was carried out on the carbon-coated lithium titanate negative electrode material prepared above. The spe...

Embodiment 3

[0042] A method for preparing a carbon-coated lithium titanate negative electrode material provided by the invention comprises the following steps:

[0043] (1) Add 1000g of titanium dioxide nanoparticles into 2500mL of 0.025mol / L tannic acid aqueous solution, ultrasonically disperse for 30min, and stir at room temperature for 3h;

[0044] (2) vacuum filter the solution in step (1), and dry the filter cake in an oven at 60°C for 48 hours to obtain compound A;

[0045] (3) Add compound A and 380g lithium carbonate together in the high-speed mixer, the high-speed mixer spindle speed is 1000r / min, and the working time is 6min to obtain compound B;

[0046] (4) The composite B was placed in a tube furnace and calcined at 800° C. for 12 hours in an inert atmosphere to obtain a carbon-coated lithium titanate negative electrode material.

[0047] The battery performance test was carried out on the carbon-coated lithium titanate negative electrode material prepared above. The specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com