A kind of preparation method of aluminum magnesium boron abrasive tool and abrasive tool

An aluminum-magnesium-boron and abrasive technology, which is used in transportation and packaging, metal processing equipment, recycling technology, etc., can solve problems such as endangering the health of operators, cumbersome steps, environmental pollution, etc., and achieves improved utilization and high reaction efficiency. , the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Figure 4 This is a schematic diagram of the microstructure of the aluminum-magnesium-boron abrasive tool prepared in Example 1.

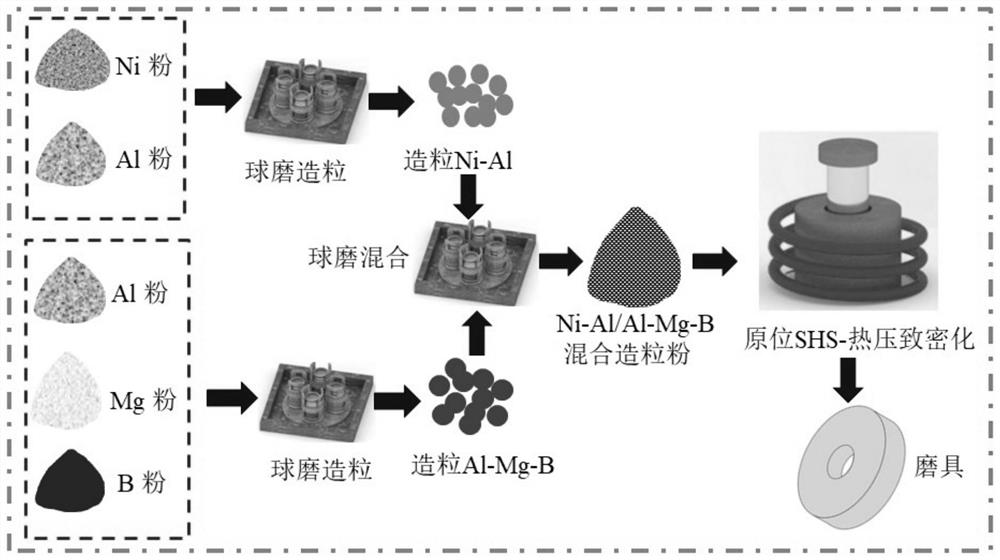

[0040] A kind of aluminum magnesium boron abrasive tool is made by the following preparation method, and the preparation method is such as figure 2 , image 3 shown, including the following steps:

[0041] Step 1: Fully mix Al powder, Mg powder and B powder according to the molar ratio of 1:1:14, and add Al powder and Mg powder respectively accounting for 4% of the total weight of the mixed powder to the mixed powder as the powder treatment process In the oxidation compensation, the purity of the Al powder and Mg powder is 99.97%, the purity of B powder is 99.8%, the particle size of Al powder is 48 μm, the particle size of Mg powder is 65 μm, and the particle size of B powder is 4 μm. Put a vacuum ball milling jar into the box, seal it and put it into a ball mill for ball milling and mixing. The vacuum ball milling jar and its grinding ...

Embodiment 2

[0047] A kind of aluminum magnesium boron abrasive tool is made by the following preparation method, and the preparation method is such as figure 2 , image 3 shown, including the following steps:

[0048] Step 1: Fully mix Al powder, Mg powder and B powder according to the molar ratio of 1:1:14, and add Al powder and Mg powder respectively accounting for 4% of the total weight of the mixed powder to the mixed powder as the powder treatment process In the oxidation compensation, the purity of the Al powder and Mg powder is 99.97%, the purity of B powder is 99.8%, the particle size of Al powder is 50 μm, the particle size of Mg powder is 70 μm, and the particle size of B powder is 5 μm. Put a vacuum ball milling jar into the box, seal it and put it into a ball mill for ball milling and mixing. The vacuum ball milling jar and its grinding balls are made of WC-Co cemented carbide materials, and the total volume of the grinding balls and raw materials does not exceed the volume ...

Embodiment 3

[0054] A kind of aluminum magnesium boron abrasive tool is made by the following preparation method, and the preparation method is such as figure 2 , image 3 shown, including the following steps:

[0055] Step 1: Fully mix Al powder, Mg powder and B powder according to the molar ratio of 1:1:14, and add Al powder and Mg powder respectively accounting for 4% of the total weight of the mixed powder to the mixed powder as the powder treatment process In the oxidation compensation, the purity of the Al powder and Mg powder is 99.97%, the purity of B powder is 99.8%, the particle size of Al powder is 45 μm, the particle size of Mg powder is 65 μm, and the particle size of B powder is 4 μm. Put a vacuum ball milling jar in the box, put it into a ball mill after sealing and mixing, the vacuum ball milling jar and its grinding balls are made of WC-Co cemented carbide materials, and the total volume of the grinding balls and raw materials does not exceed the volume of the ball milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com