Method for enriching anaerobic ammonium oxidation bacteria by utilizing tannery wastewater and activated sludge of biochemical system of tannery wastewater

An anaerobic ammonia oxidizing bacteria and biochemical system technology, applied in the field of sewage treatment, can solve the problems of high cost, harsh environmental requirements, long generation cycle, etc., and achieve the effects of strong impact resistance, reduced labor intensity, and high ammonia nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

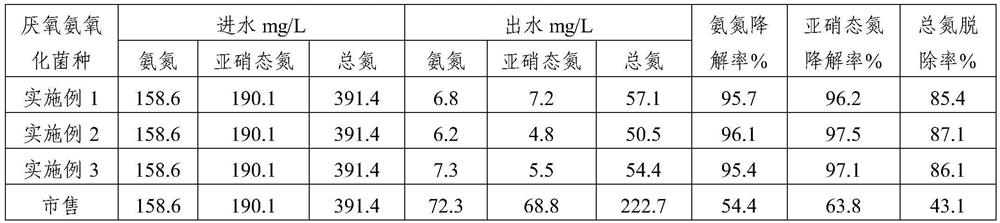

Embodiment 1

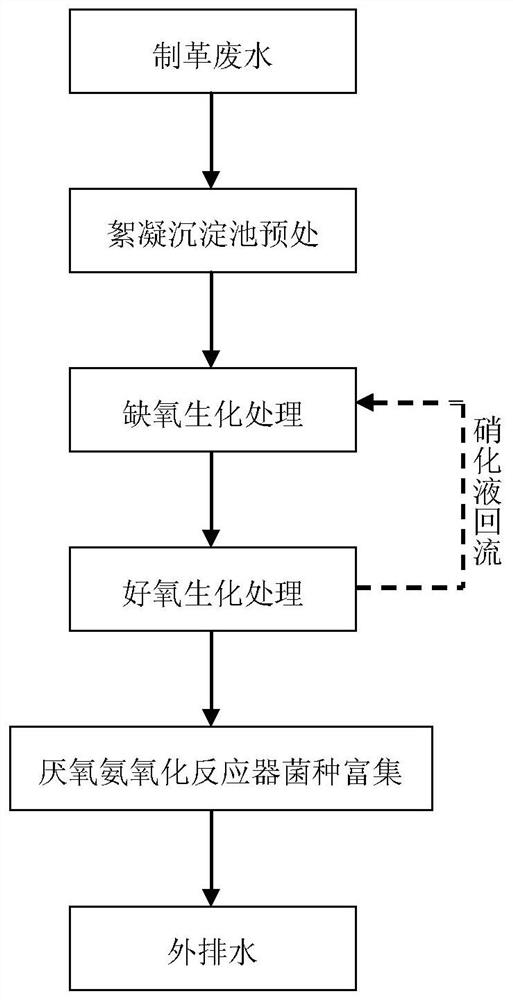

[0034] A method for enriching anammox bacteria by utilizing tannery wastewater and activated sludge of its biochemical system, the specific steps comprising:

[0035] Tannery A wastewater (ammonia nitrogen 1000-1200mg / L, COD 3000-3500mg / L) enters the flocculation sedimentation tank and then adds polyferric sulfate 0.8kg / m 3 , ferrous sulfate 1.5kg / m 3 , react for 20min, then add polyacrylamide 0.03kg / m 3 , react for 15min, finally add calcium oxide 3.2kg / m 3 , Precipitating suspended solids in raw water and ions toxic to microorganisms into physical sludge to complete wastewater pretreatment.

[0036]After pretreatment, the wastewater enters the anoxic pool. The process parameters of the anoxic pool are: temperature 25±2°C, pH 7.0-7.2, dissolved oxygen 0.2-0.3mg / L, residence time 20-24h, control effluent COD<1500mg / L Enter the aerobic pool; after entering the aerobic pool, the process parameters of the aerobic pool are: temperature 25±2°C, pH 7.5-7.8, dissolved oxygen 1.0±0...

Embodiment 2

[0040] A method for enriching anammox bacteria by utilizing tannery wastewater and activated sludge of its biochemical system, the specific steps comprising:

[0041] Tannery B wastewater (ammonia nitrogen 300-400mg / L, COD 800-1000mg / L) enters the flocculation sedimentation tank and then adds ferrous sulfate 0.3kg / m 3 , react for 20min, then add polyacrylamide 0.01kg / m 3 , react for 15min, finally add calcium oxide 1.1kg / m 3 , Precipitating suspended solids in raw water and ions toxic to microorganisms into physical sludge to complete wastewater pretreatment.

[0042] After pretreatment, the wastewater enters the anoxic pool. The process parameters of the anoxic pool are: temperature 30°C, pH 7.0-7.2, dissolved oxygen 0.2-0.3mg / L, residence time 12-14h, control effluent COD<500mg / L to enter Oxygen tank: After entering the aerobic tank, the process parameters of the aerobic tank are: temperature 30°C, pH 7.7-7.8, dissolved oxygen 1.5±0.1mg / L controlled by micro-aeration and p...

Embodiment 3

[0046] A method for enriching anammox bacteria by utilizing tannery wastewater and activated sludge of its biochemical system, the specific steps comprising:

[0047] Tannery C wastewater (ammonia nitrogen 500-550mg / L, COD 1500-1800mg / L) enters the flocculation sedimentation tank and then adds ferrous sulfate 0.4kg / m 3 , reacted for 20min, then added polyaluminum chloride 0.6kg / m 3 , react for 15min, add polyacrylamide 0.01kg / m 3 , react for 15min, finally add calcium oxide 2.8kg / m 3 , Precipitating suspended solids in raw water and ions toxic to microorganisms into physical sludge to complete wastewater pretreatment.

[0048] After pretreatment, the wastewater enters the anoxic pool. The process parameters of the anoxic pool are: temperature 30°C, pH 7.3-7.4, dissolved oxygen 0.2-0.3mg / L, residence time 18-20h, control effluent COD<700mg / L to enter Oxygen tank: After entering the aerobic tank, the process parameters of the aerobic tank are: temperature 30°C, pH 7.5-7.6, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com