Autotomy-resistant high-specific-activity trypsin mutant

A technology of trypsin and mutants, which is applied in the field of protein and genetic engineering, can solve the problems of affecting the application efficiency and level, the decrease of enzyme activity, etc., and achieve the characteristics of easy self-cutting and low activity, high specific activity, and good anti-self-cutting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1. Cloning of pig-derived trypsinogen gene.

[0058] According to the amino acid sequence of wild porcine trypsinogen, Pichia pastoris was selected as the expression host for codon optimization to obtain trypsinogen Pichia optimized gene (SEQ ID NO.1), and the wild-type trypsinogen gene (SEQ ID NO.1) was synthesized. .1), designing primers and amplifying the gene by PCR technology, using T4 ligase to connect the amplified gene fragment to the vector pMD19T to obtain the recombinant cloning vector pMD19T-try. Transformation into Escherichia coli JM109 competent cells.

Embodiment 2

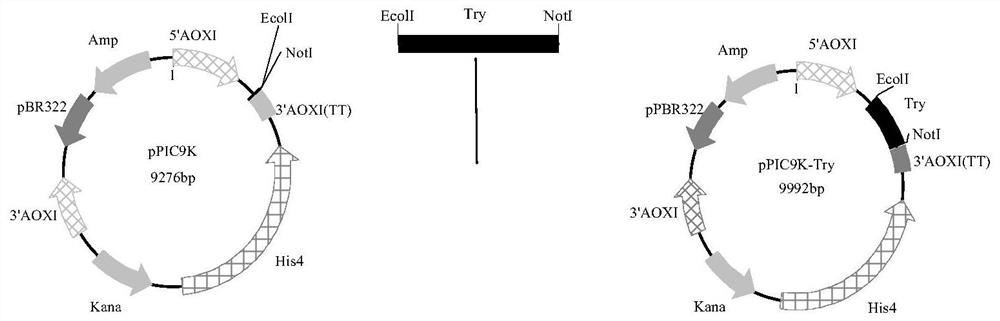

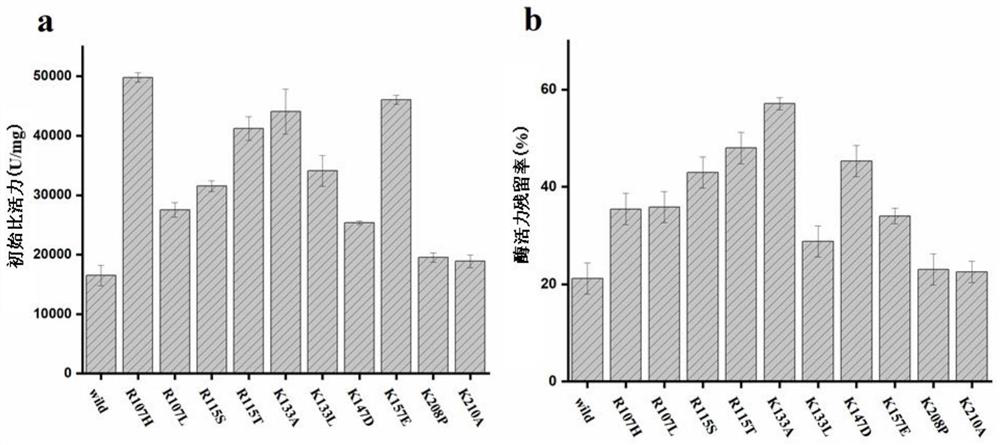

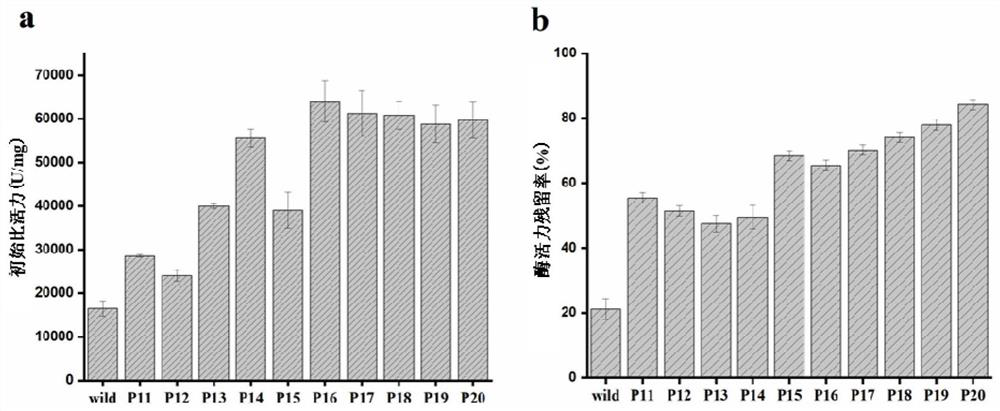

[0059] Embodiment 2, site-directed mutagenesis

[0060] The process of site-directed mutagenesis is as follows: using the constructed PMD19T-try as a template, design corresponding primers for inverse PCR, at the corresponding 107th, 115th, 133rd, 147th, 157th, 208th and 210th amino acid positions Point-introduced single-point or combined mutations, the primer sequences are shown in Table 2. Use Dpn I restriction endonuclease to remove the original template, verify the amplified product by agarose electrophoresis and purify the recovered product, transform the recovered plasmid into Escherichia coli, extract the plasmid from the constructed strain, and perform single enzyme digestion and double enzyme digestion verification and sequencing, and extract the recombinant plasmid pMD19T-M-try (M represents the corresponding mutant); the constructed recombinant plasmid pMD19T-M-try (M represents the corresponding mutant) and the expression vector pPIC9K were respectively used Ecol ...

Embodiment 3

[0064] Embodiment 3, shake flask fermentation of recombinant Pichia pastoris

[0065] Inoculate the strains into YPD solid medium for three-section line, culture at 28°C for 2 days; pick a single colony from the YPD solid plate to YPD liquid medium, culture at 28°C, 200rpm for 24h; inoculate YPD liquid culture with 2% inoculum The cultured seed solution was transferred to BMGY medium, and cultivated at 28°C and 200rpm to the OD of the bacterial solution 600 2-6, then transfer it to a sterile centrifuge tube and centrifuge at 5000rpm for 10min to retain the bacteria; add an appropriate amount of BMMY and repeat centrifugation to remove residual glycerol; transfer to BMMY medium, add methanol to a final concentration of 0.5%; then every 12h Add methanol at a final concentration of 0.5% to induce culture for 96 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com