Application of a gas sensor and si-rgo composite material in the preparation of gas sensor

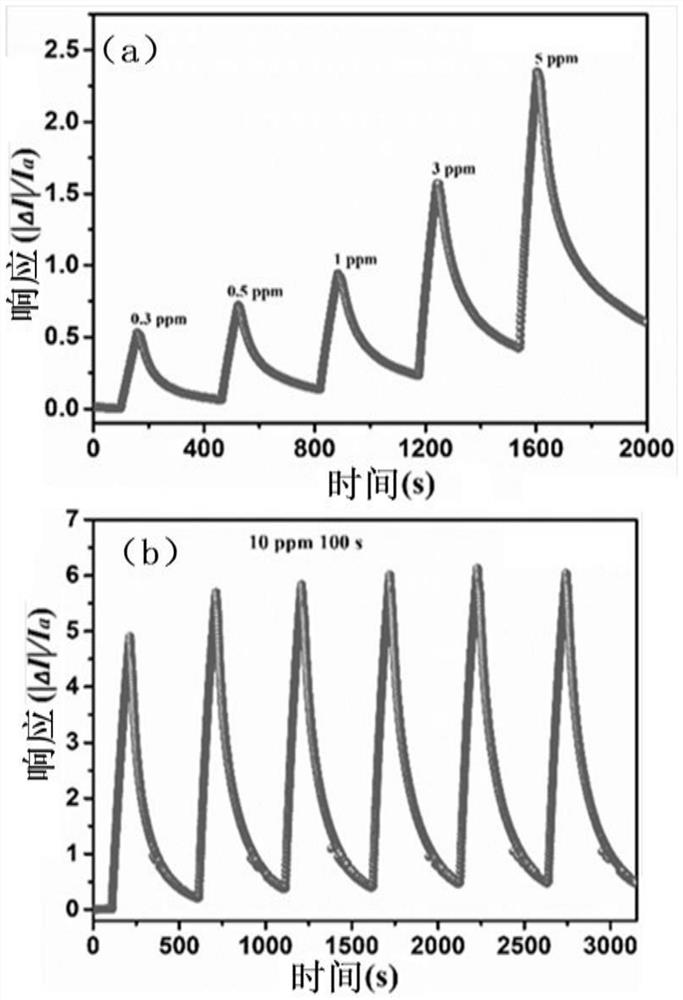

A gas sensor and composite material technology, applied in the direction of material resistance, analytical materials, and material electrochemical variables, can solve the problem of poor contact stability between graphene and silicon quantum dots, poor control of device uniformity, and no reports on gas sensors and other issues, to achieve the effect of low power consumption, stable structure, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) 45 mg of GO sheets were dissolved in 100 mL of deionized water as solution 1, 0.1 M aqueous ammonia solution as solution 2, and 0.1 M aqueous glucose solution as solution 3.

[0050] (2) 0.5 mL of silane coupling agent (KH-550) was added to 10 mL of solution 1, and the pH was adjusted to 8.5 by solution 2.

[0051] (3) 5 mL of ethanol was added to the solution obtained in step (2), and mixed uniformly by magnetic stirring, the stirring time was 180 min, and the reaction temperature was 25°C. After the reaction, the GO product grafted with Si quantum dots was obtained in the solution.

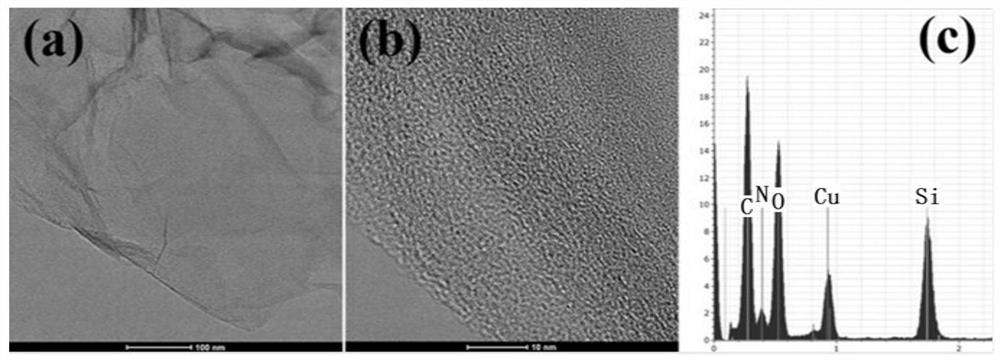

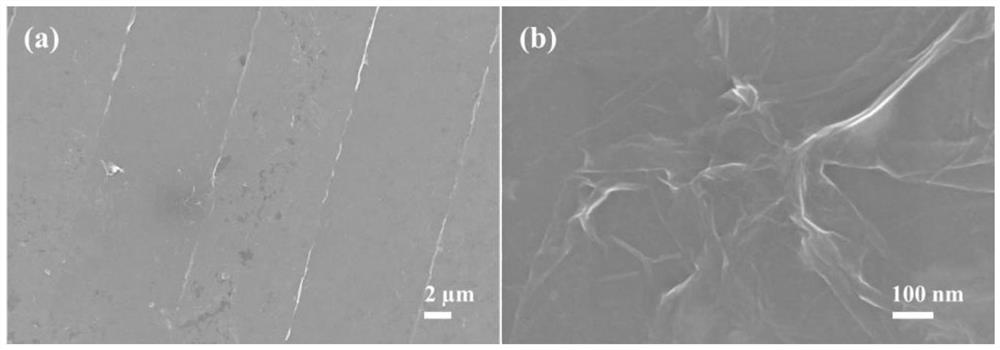

[0052] (4) 10 mL of solution 3 was slowly added dropwise to the solution obtained in step (3), and after magnetic stirring was uniformly mixed, the reaction was performed in a water bath at 80° C. for 30 min to obtain a Si-RGO composite material. The composite material is composed of RGO nanosheets and Si quantum dots grafted on its surface. The mass ratio of Si quantum dots and RGO ...

Embodiment 2

[0060] (1) 45 mg of GO sheets were dissolved in 100 mL of deionized water as solution 1, 0.1 M aqueous ammonia solution as solution 2, and 0.1 M aqueous glucose solution as solution 3.

[0061] (2) 0.5 mL of silane coupling agent (KH-550) was added to 10 mL of solution 1, and the pH was adjusted to 9.0 by solution 2.

[0062] (3) 10 mL of ethanol was added to the solution obtained in step (2), and mixed uniformly by magnetic stirring, the stirring time was 180 min, and the reaction temperature was 25°C. After the reaction, the GO product grafted with Si quantum dots was obtained in the solution.

[0063] (4) 30 mL of solution 3 was slowly added dropwise to the solution obtained in step (3), and after magnetic stirring was uniformly mixed, the reaction was carried out in a 40° C. water bath for 30 min to obtain a Si-RGO composite material. The composite material is composed of RGO nanosheets and Si quantum dots grafted on its surface. The mass ratio of Si quantum dots and RGO ...

Embodiment 3

[0068] (1) 45 mg of GO sheets were dissolved in 100 mL of deionized water as solution 1, 0.1 M aqueous ammonia solution as solution 2, and 0.5 M aqueous glucose solution as solution 3.

[0069] (2) 0.2 mL of silane coupling agent (KH-550) was added to 10 mL of solution 1, and the pH was adjusted to 9.5 by solution 2.

[0070] (3) 5 mL of ethanol was added to the solution obtained in step (2), and mixed uniformly by magnetic stirring, the stirring time was 180 min, and the reaction temperature was 25°C. After the reaction, the GO product grafted with Si quantum dots was obtained in the solution.

[0071] (4) 15 mL of solution 3 was slowly added dropwise to the solution obtained in step (3), and after magnetic stirring was uniformly mixed, the reaction was carried out in a 60° C. water bath for 30 min to obtain a Si-RGO composite material. The composite material is composed of RGO nanosheets and Si quantum dots grafted on its surface. The mass ratio of Si quantum dots and RGO i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com