Preparation method of supported NiPd bimetallic catalyst and application of supported NiPd bimetallic catalyst in dehalogenation reaction

A bimetallic catalyst, supported technology, applied in catalyst activation/preparation, preparation of organic compounds, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as unrelevant disclosure, and achieve cost reduction , improve catalytic activity, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation method of supported NiPd bimetallic catalyst comprises the following steps:

[0066] (1) Accurately weigh 0.1g sodium chloropalladate (Na 2 PdCl 4 ), 0.0269g nickel chloride (NiCl 2 ·6H 2 (2) and 20mL deionized water are added in the 100mL round bottom flask A, and magnetic stirring makes sodium chloropalladate and nickel chloride be completely dissolved in deionized water, and the solution is transparent reddish brown;

[0067] (2) Add pre-prepared 50mg graphene oxide (GO) and 10mL deionized water into a 100mL round-bottomed flask B, ultrasonicate it for 2h until graphene oxide is completely dissolved in deionized water, and the solution is muddy yellow;

[0068] (3) Add the graphene oxide aqueous solution in the round bottom flask B to the round bottom flask A drop by drop, the rate of addition is about 60 drops per minute, and ultrasonic treatment is performed while adding, and the ultrasonic treatment is continued for 1 h after the addition, so th...

Embodiment 2

[0074] The present inventor carried out transmission electron microscope (TEM) characterization, high-resolution transmission electron microscope (HRTEM) characterization, X-ray powder diffraction (XRD) characterization to the loaded type NiPd bimetallic catalyst obtained in embodiment 1, and the results are as follows:

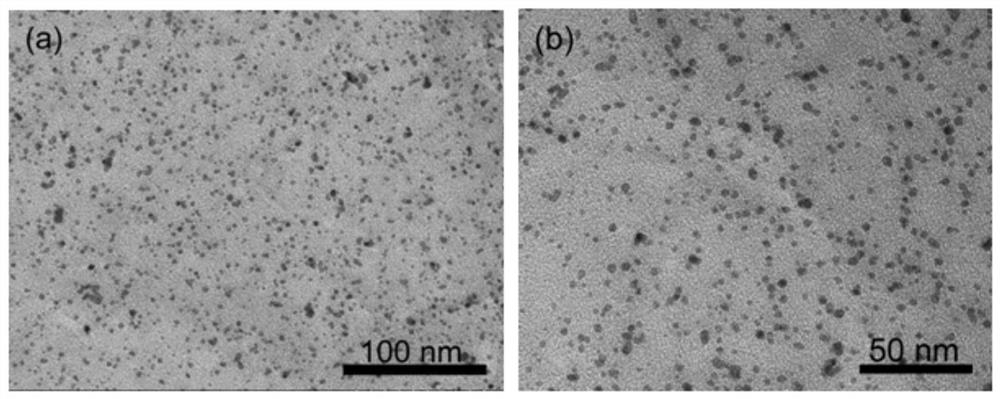

[0075] 1. Transmission electron microscopy (TEM) characterization

[0076] Ni was examined by transmission electron microscopy (TEM). 1 PD 3 The @rGO catalyst was characterized as figure 1 As shown in (a) and (b), the catalyst is uniformly dispersed, uniform in size, without obvious agglomeration, and its particle size is about 4nm.

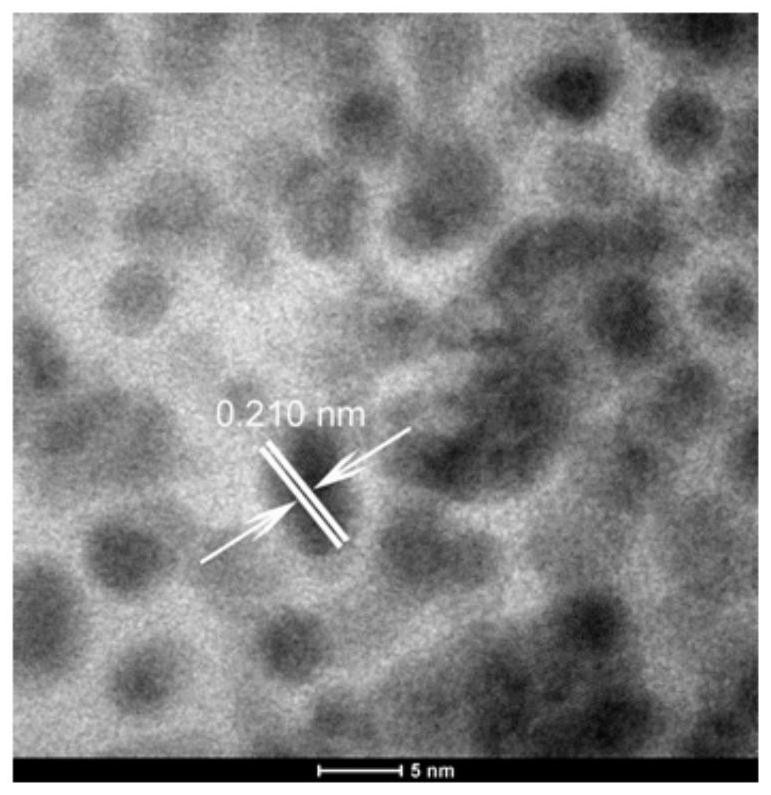

[0077] 2. Characterization by High Resolution Transmission Electron Microscopy (HRTEM)

[0078] Ni was examined by high-resolution transmission electron microscopy (HRTEM). 1 PD 3 The @rGO catalyst was characterized as figure 2 As shown, its lattice spacing is 0.210nm.

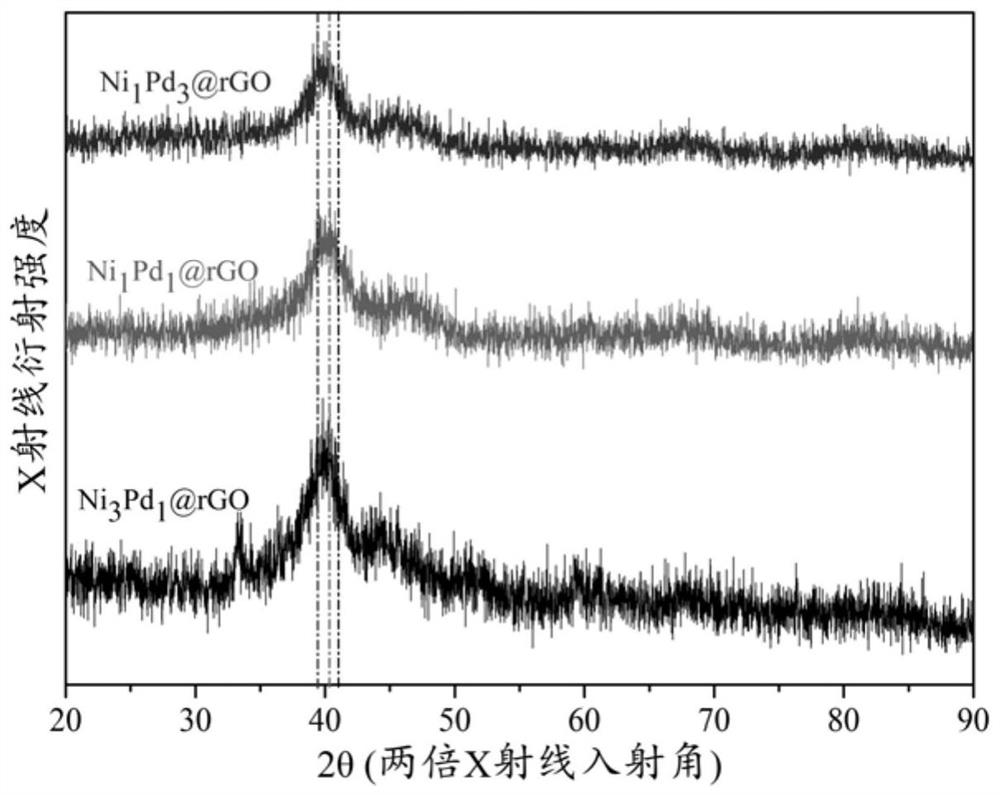

[0079] 3. X-ray powder diffraction (XRD) character...

Embodiment 3

[0082] The supported NiPd bimetallic catalyst obtained in Example 1 is applied to the dehalogenation reaction of catalyzed halogenated aromatic hydrocarbons, specifically as follows:

[0083] 1. Ni 1 PD 3 Optimization of @rGO Catalyzed Chlorobenzene Dechlorination Reaction Conditions

[0084] At present, in the field of catalytic chemistry, precious metals such as gold (Au), ruthenium (Ru), rhodium (Rh), iridium (Ir), and platinum (Pt), which are expensive and difficult to obtain, are mainly used as catalysts. In the present invention, metal Ni and transition metal Pd that are cheap and easy to obtain are used to load on reduced graphene oxide (Ni 1 PD 3 @rGO) as a catalyst is of great significance in catalytic chemistry, so Ni 1 PD 3 @rGO has shown promising applications in the catalytic industry.

[0085] Ni 1 PD 3 The steps for @rGO to catalyze the dechlorination of chlorobenzene are as follows:

[0086] Accurately weigh 10mgNi 1 PD 3 The @rGO catalyst was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com