Non-gel and non-precipitation high-concentration laundry detergent and preparation method thereof

A high-concentration, laundry detergent technology, used in the field of daily chemicals, can solve the problems of poor performance at low temperature, affecting production efficiency, and high water content, and achieve the effects of good low-temperature rheology, improved sebum detergency, and smooth viscosity changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

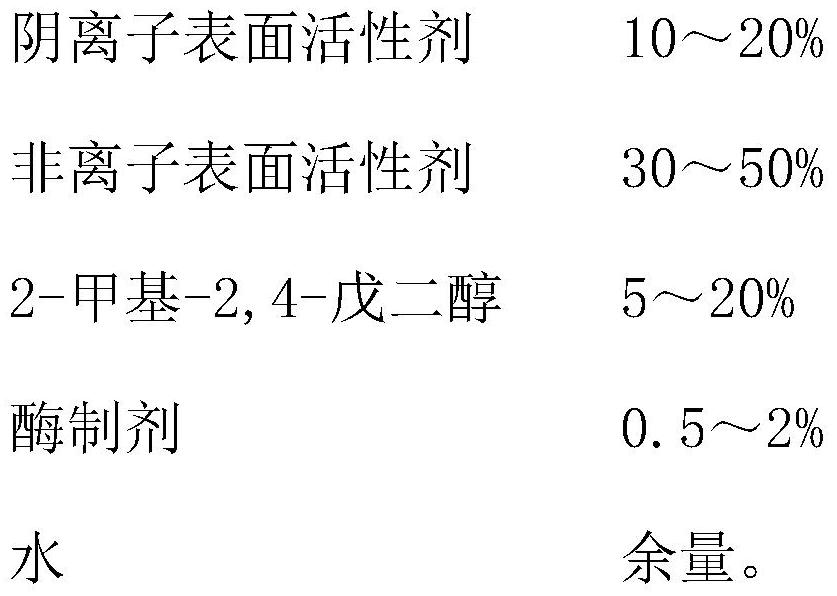

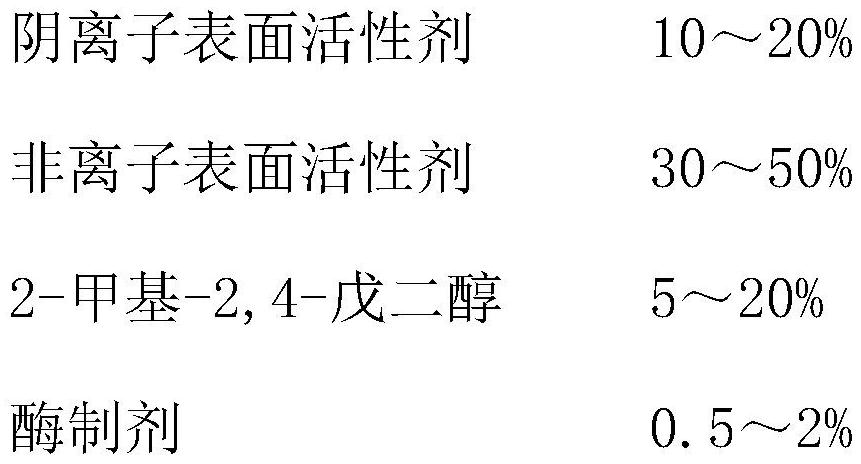

[0059] A kind of preparation method of the highly concentrated laundry liquid that does not gel and does not separate out, comprises the following steps:

[0060] A. Take anionic surfactant, nonionic surfactant, 2-methyl-2,4-pentanediol, enzyme preparation, essence, preservative and water according to the formula quantity;

[0061] B. Add 2-methyl-2,4-pentanediol, fatty acid methyl ester ethoxylate and isomeric fatty alcohol polyoxyethylene ether into the water of formula quantity and stir evenly, then add nonionic surfactant and stir evenly Finally, add anionic surfactant and stir evenly;

[0062] C. Selectively add enzyme preparation, essence and preservatives, and stir evenly to prepare a highly concentrated laundry detergent that does not gel or separate out.

[0063] The introduction of the 2-methyl-2,4-pentanediol and the compounding of the fatty acid methyl ester ethoxylate (FMEE) and isomerized fatty alcohol polyoxyethylene ether (CA-60) eliminated all The gel proble...

Embodiment 1、2、4 and comparative example 1-6

[0070] A kind of highly concentrated laundry detergent, prepared according to the following steps:

[0071] (1) Calculated according to mass percentage, each raw material is taken by weighing the raw material component content of Table 2 for subsequent use (wherein potassium cocoate is prepared by potassium hydroxide and coconut oil acid, calculated according to mass percentage, the consumption of potassium hydroxide accounts for the total amount of raw materials 0.9% of the consumption, the consumption of coconut oleic acid accounts for 3% of the total consumption of raw materials)

[0072] (2) Preparation of Potassium Coconut Oleate: Add the 2-methyl-2,4-pentanediol and potassium hydroxide weighed in the step (1) to the water of the formula and stir evenly, then slowly add coconut oleic acid for neutralization React until the pH value of the liquid reaches 8.0, and the reaction is complete;

[0073] (3) Add fatty acid methyl ester ethoxylate (FMEE) and isomeric fatty alcoho...

Embodiment 3

[0076] A kind of highly concentrated laundry detergent, prepared according to the following steps:

[0077] (1) Calculate according to mass percentage, and each raw material is taken by weighing the raw material component content of Table 2 for subsequent use (wherein the active substance content of potassium cocoate is 30%);

[0078] (2) Add the 2-methyl-2,4-pentanediol, fatty acid methyl ester ethoxylate (FMEE) and isomerized fatty alcohol polyoxyethylene ether (CA-60) weighed in step (1) Stir evenly in the water of formula quantity, then add nonionic surfactant and stir evenly, then add anionic surfactant and stir evenly;

[0079] (3) Add enzyme preparation, stir well and make a kind of highly concentrated laundry detergent, then take samples for performance test.

[0080] Table 2 - Raw material component content

[0081]

[0082]

[0083] Table 2 (continued) - Raw material component content

[0084]

[0085]

[0086] Table 3-embodiment and comparative example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com