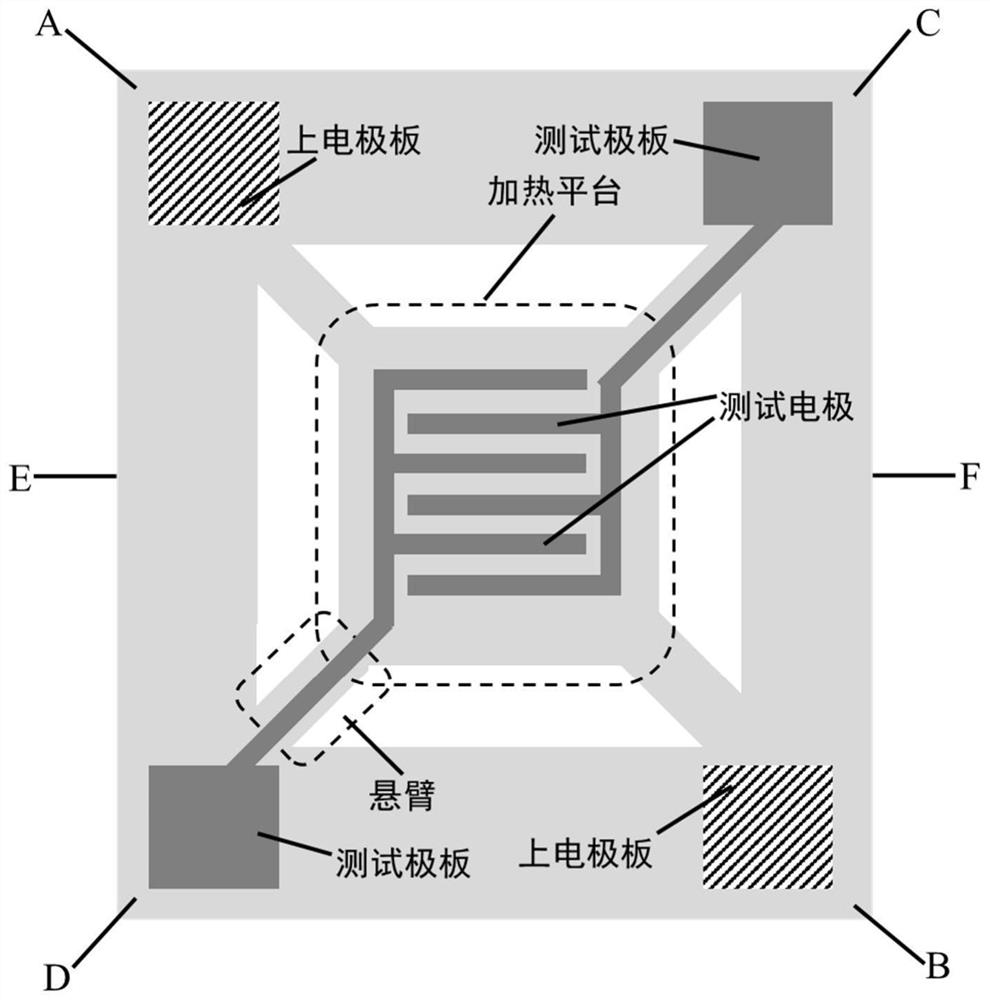

MEMS micro hot plate based on air thermal insulation layer and manufacturing method of MEMS micro hot plate

A technology of air heat insulation layer and micro-hot plate, which is applied to the process, coating, and electrical components used to produce decorative surface effects, and can solve the problem of uneven temperature distribution of MEMS micro-hot plates, affecting the gas sensor characteristics of gas sensors, Problems such as high power of MEMS micro-hot plate, to achieve the effect of reducing loss, suppressing loss, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Making the thickness t of the air insulation layer a 0.5 μm, p-type (100) silicon chip thickness h is 200 μm MEMS micro-hot plate based on air insulation layer.

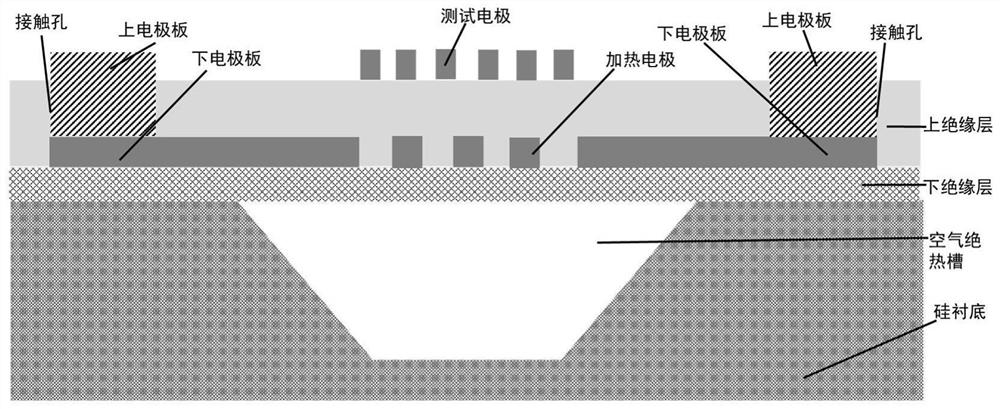

[0044] Step 1, making the lower insulating layer on the silicon substrate, such as Image 6 a.

[0045] On silicon substrates, using thermal oxidation technology, that is, in O 2 Under the technological conditions of flow rate of 20sccm, pressure of 20mT, and temperature of 500°C, a layer of thickness t d 1µm SiO 2 The insulating medium forms the lower insulating layer.

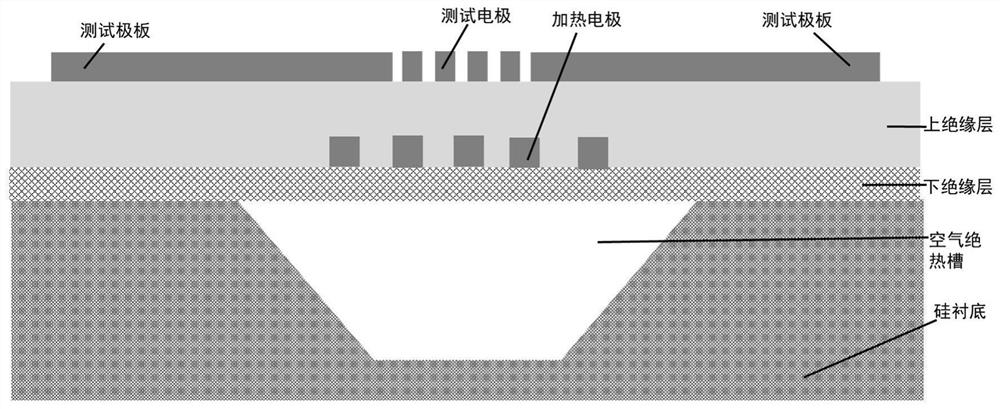

[0046] Step 2, making a sacrificial layer on the lower insulating layer, such as Image 6 b.

[0047] On the lower insulating layer, use chemical vapor deposition technology, that is, in the reaction chamber temperature of 1200 ° C, SiCl 4 Flow at H 2 The molar percentage in is 5%, and the film growth rate is 2.2μm / min under the process conditions, depositing a layer thickness t a 0.5μm polysilicon;

[0048] Use reacti...

Embodiment 2

[0063] Embodiment 2: Making the thickness t of the air insulation layer a 1 μm, p-type (100) silicon chip thickness h is 300 μm MEMS micro-hot plate based on air insulation layer.

[0064] Step 1, making a lower insulating layer on the silicon substrate, such as Image 6 a.

[0065] A layer of thickness t is grown on a silicon substrate by thermal oxidation d 2µm SiO 2 The insulating medium forms the lower insulating layer.

[0066] The processing condition of described thermal oxidation technology is: O 2 The flow rate is 30 sccm, the pressure is 80 mT, and the temperature is 550°C.

[0067] Step 2, making a sacrificial layer, such as Image 6 b.

[0068] 2.1) Deposit a layer thickness t on the lower insulating layer by using chemical vapor deposition technology a 1μm polysilicon;

[0069] 2.2) A mask is made on the surface of the polysilicon, and the easily corroded material layer is etched into a rectangular parallelepiped sacrificial layer by reactive ion etching ...

Embodiment 3

[0091] Embodiment three: making air heat insulation layer thickness t a 2μm, p-type (100) silicon chip thickness h is 500μm MEMS micro hot plate based on air insulation layer.

[0092] Step A, making a lower insulating layer on the silicon substrate, such as Image 6 a.

[0093] Using thermal oxidation technology in O 2 The flow rate is 40 sccm, the pressure is 100mT, and the temperature is 600°C, a layer of thickness t is grown on the silicon substrate d 5µm SiO 2 The insulating medium forms the lower insulating layer.

[0094] Step B, making a sacrificial layer on the lower insulating layer, such as Image 6 b.

[0095] First, using chemical vapor deposition technology in the reaction chamber temperature of 1200 ° C, SiCl 4 Flow at H 2 Deposit a layer of thickness t on the lower insulating layer under the condition that the molar percentage in the film is 5%, and the film growth rate is 2.2 μm / min. a 2μm polysilicon;

[0096] Then, make a mask on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com