Preparation of super-hydrophilic SiO2/PDAus/PVDF composite membrane

A super-hydrophilic, composite membrane technology, applied in water/sludge/sewage treatment, water/sewage treatment, osmotic/dialysis water/sewage treatment, etc. Extensive practicability It is difficult to prepare, and the membrane pore structure is difficult to control. It can solve the problems of unevenness and embedding, good anti-pollution performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

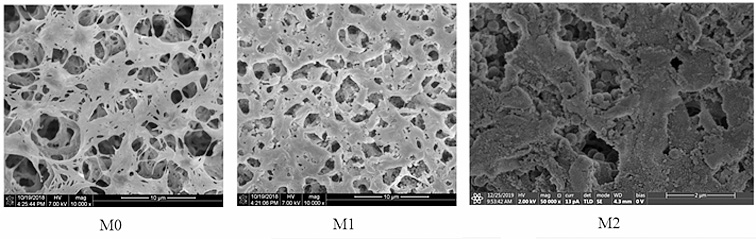

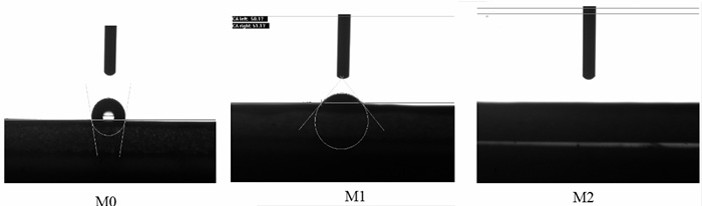

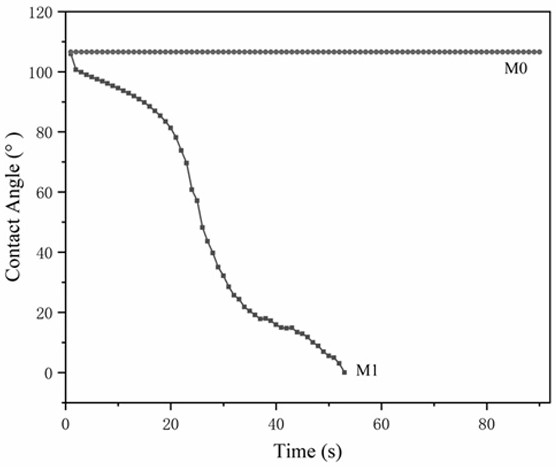

[0022] A SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation method, the specific steps are:

[0023] (1) Preparation of dopamine-modified PDAus / PVDF composite membrane:

[0024] First mix deionized water and absolute ethanol at a volume ratio of 1:1, add Tris-phosphate neutral buffer to make a solution with a Tris concentration of 10 mmol / L, then dissolve dopamine powder into the solution, and stir 1 day, make a dopamine solution with a concentration of 0.5 mg / ml, then add the original PVDF membrane into the obtained dopamine solution, continue to stir for 3 days, and finally wash the membrane and let the membrane dry for 2 days to obtain the modified PDAus / PVDF composite membrane.

[0025] (2) SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation:

[0026] Weigh 0.2g of lysine and dissolve it in 100ml of ultrapure water, then add 3ml of tetraethyl orthosilicate (TEOS), and then add 0.01mol / L of HNO 3 Solution, so...

Embodiment 2

[0028] A SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation method, the specific steps are:

[0029] (1) Preparation of dopamine-modified PDAus / PVDF composite membrane:

[0030] First mix deionized water and absolute ethanol at a volume ratio of 5:2, add Tris-phosphate neutral buffer to make a solution with a Tris concentration of 10 mmol / L, then dissolve dopamine powder into the solution, and stir 1 day, make a dopamine solution with a concentration of 1.0mg / ml, then add the original PVDF membrane into the dopamine solution, continue to stir for 3 days, and finally wash the membrane and let the membrane dry for 2 days to obtain the modified PDAus / PVDF composite membrane.

[0031] (2) SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation:

[0032] Weigh 0.3g of lysine and dissolve it in 100ml of ultrapure water, then add 5ml of tetraethyl orthosilicate (TEOS), and then add 0.01mol / L of HNO 3 solution, so that the ...

Embodiment 3

[0034] A SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation method, the specific steps are:

[0035] (1) Preparation of dopamine-modified PDAus / PVDF composite membrane:

[0036] First mix deionized water and absolute ethanol at a volume ratio of 5:2, add Tris-phosphate neutral buffer to make a solution with a Tris concentration of 10 mmol / L, then dissolve dopamine powder into the solution, and stir 1 day, make a dopamine solution with a concentration of 1.5 mg / ml, then add the original PVDF membrane into the dopamine solution, continue to stir for 3 days, and finally wash the membrane and let the membrane dry for 2 days to obtain the modified PDAus / PVDF composite membrane.

[0037] (2) SiO with superhydrophilic properties 2 / PDAus / PVDF composite membrane preparation:

[0038] Weigh 0.4g of lysine and dissolve it in 100ml of ultrapure water, then add 7ml of tetraethyl orthosilicate (TEOS), and then add 0.01mol / L of H 2 SO 4 Solution, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com