A kind of ablation-resistant nanoporous resin-based composite material and preparation method thereof

A composite material and nanopore technology, which is applied in the field of ablation-resistant nanoporous resin-based composite materials and its preparation, can solve the problems of poor damage resistance, poor processability, high thermal conductivity and density, etc., and achieve high-temperature emissivity , The effect of improving ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

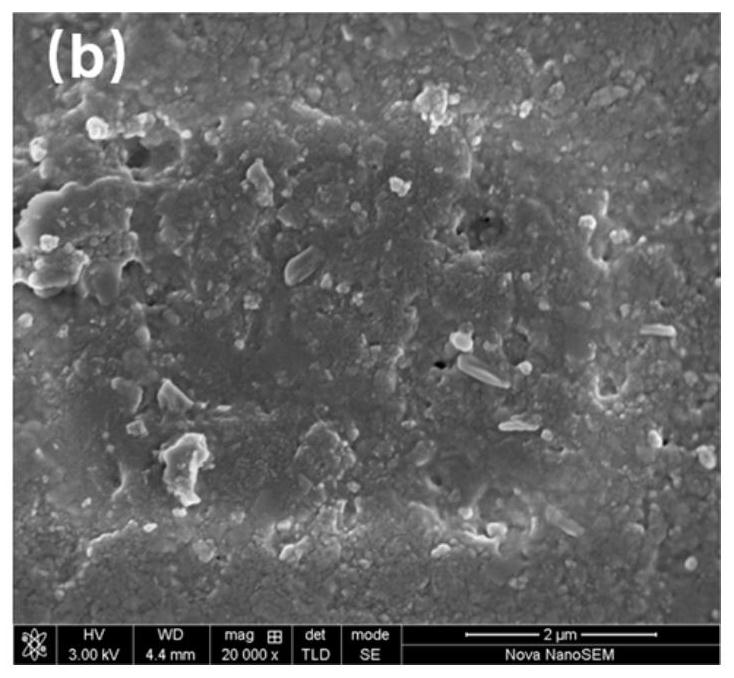

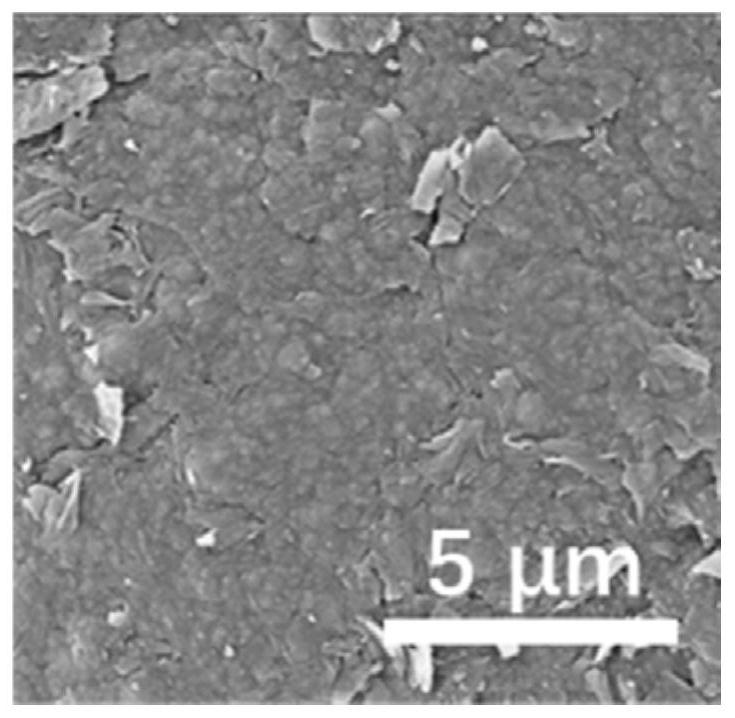

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of ablation-resistant nanoporous resin-based composite material, the method comprises the following steps:

[0048] (1) Configuration of resin solution: dissolve phenolic resin by polar solvent isopropanol and add curing agent hexamethylenetetramine of 14% of the quality of phenolic resin to obtain a resin solution with a concentration of 15ωt%;

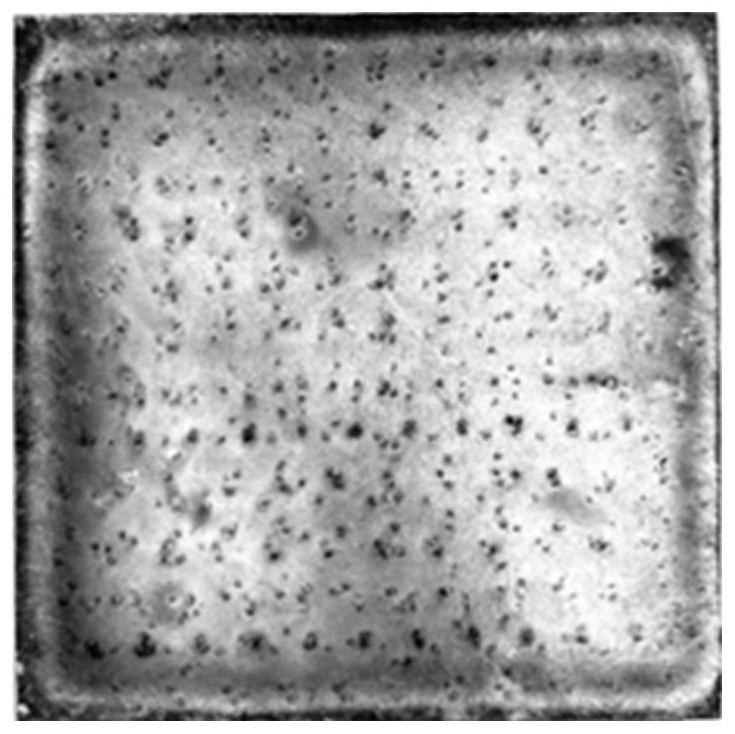

[0049] (2) Low pressure impregnation: the density is 0.15g / cm 3 , the quartz fiber mat with the size of 150mm×150mm×10mm is placed in the mold, and the resin solution is completely impregnated with the quartz fiber mat, and the impregnation pressure is normal pressure;

[0050] (3) Sol-gel reaction: the mold is sealed, and the sol-gel reaction is carried out at 80°C, and the reaction is cooled to room temperature after 48 hours to obtain a composite material;

[0051] (4) Drying at atmospheric pressure: open the mold, and then place the composite material under normal temperature and pressure for 48 hours...

Embodiment 2

[0056] The difference from Example 1 is that in the step (6), the concentration of the ceramic organic precursor solution is 10ωt%, the viscosity is less than 300cps, the quality of the composite material is increased by about 2%, the ablation-resistant nanoporous resin-based composite material, phenolic resin, The mass ratio of quartz fiber and ceramic body is 36:64:2.

Embodiment 3

[0058] The difference from Example 1 is that in the step (6), the concentration of the ceramic organic precursor solution is 15ωt%, the viscosity is less than 300cps, and the quality of the composite material is increased by about 3%. The mass ratio of quartz fiber and ceramic body is 36:64:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com