Method and device for preparing olefin and aromatic hydrocarbon through catalytic conversion of petroleum hydrocarbon raw material

A technology for catalytic conversion and petroleum hydrocarbons, which is used in hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, catalysts and other directions. coke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

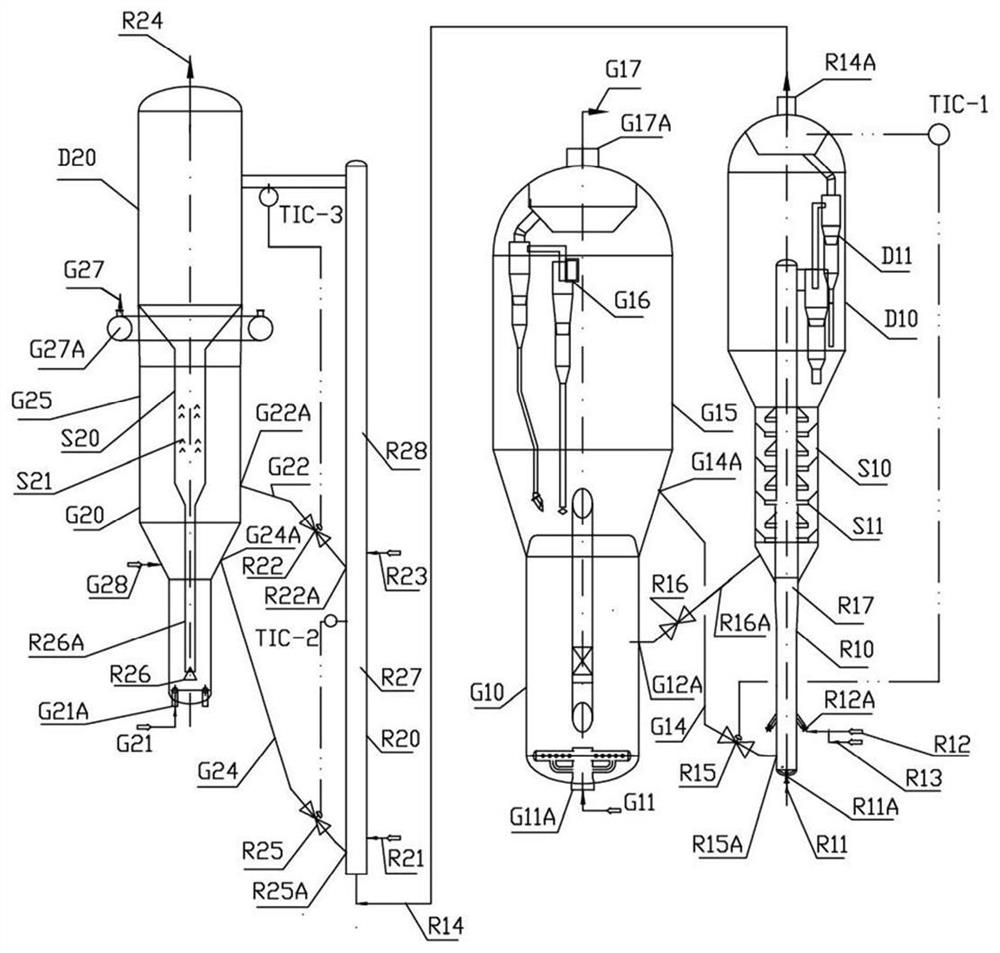

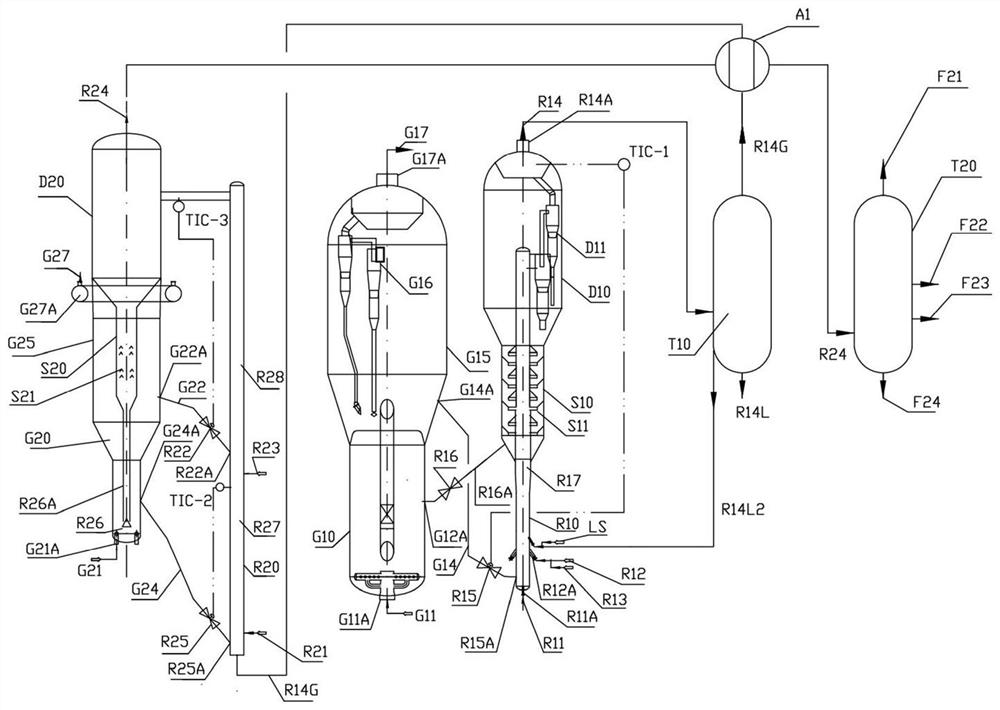

[0079] The method for producing olefins and aromatics by catalytic conversion of petroleum hydrocarbon raw materials in this embodiment adopts figure 1 The catalytic conversion device shown is equipped with a first reaction regeneration system and a second reaction regeneration system, and uses heavy petroleum hydrocarbons as raw materials. During specific implementation, the raw materials for heavy petroleum hydrocarbons can be vacuum wax oil, atmospheric heavy oil, residual oil , one or a mixture of coking wax oil, deasphalted oil, hydrogenated wax oil, hydrogenated residual oil, hydrogenated catalytic diesel oil, crude oil, and condensate oil, with a boiling point higher than 320°C;

[0080] The first reaction regeneration system is provided with the first reactor R10, the first settler D10, the first stripping section S10 and the first regenerator G10, the first reactor R10 is arranged side by side with the first regenerator G10, and the first reactor R10 The outlet is con...

Embodiment 1

[0087] A factory uses petroleum hydrocarbons as raw materials to catalytically convert olefins and aromatics, using equipment and processes such as figure 1 As shown, the implementation parameters are as follows: the heavy petroleum hydrocarbon raw material R12 is vacuum wax oil, and the parameters are shown in Table 1.

[0088] Table 1 Properties of vacuum wax oil

[0089] Density, g / ml 0.89 H, % (weight) 13.2 Carbon residue, % (weight) 4.0 Saturated hydrocarbons, % (weight) 69 Aromatics, % (weight) 28 Colloid, % (weight) 3

[0090] The raw material preheating temperature is 220°C;

[0091] The first reaction regeneration system: the settler and regenerator are arranged side by side, the charred tank is regenerated in the form of fast fluidized bed and dense phase fluidized bed, and the second reaction regeneration system: the settler and regenerator are arranged coaxially up and down, and external reactor Form; the first reactio...

Embodiment approach 2

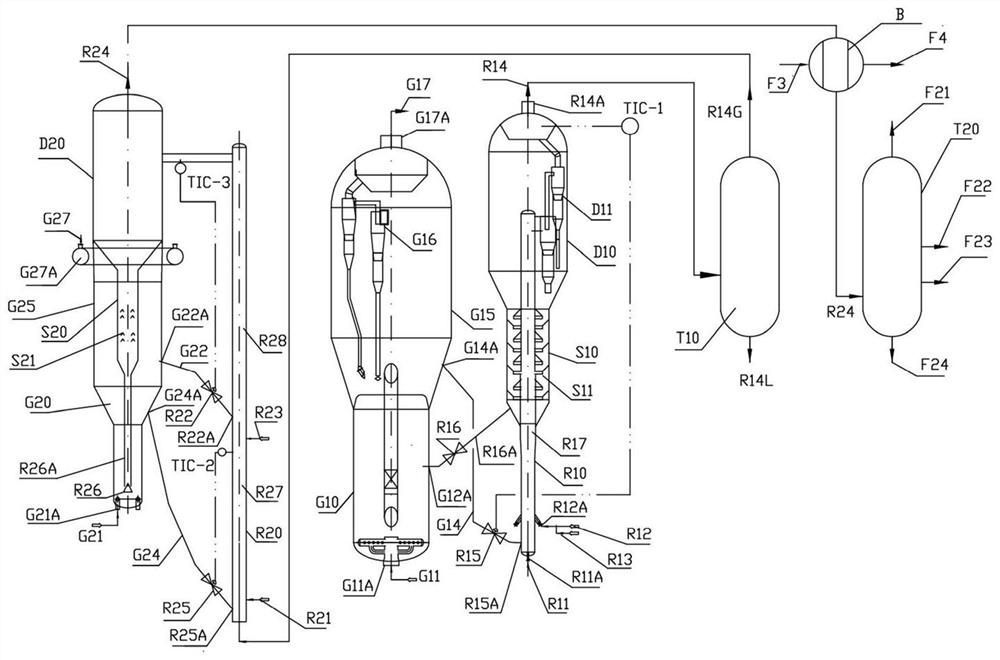

[0105] The method for producing olefins and aromatics by catalytic conversion of petroleum hydrocarbon raw materials in this embodiment adopts figure 2 The catalytic conversion device shown is equipped with a first reaction regeneration system and a second reaction regeneration system, and uses heavy petroleum hydrocarbons as raw materials;

[0106] During specific implementation, the second regenerator G20 adopts a two-stage regeneration form in series up and down. The second spent agent first enters the first-stage regeneration zone, contacts and reacts with the burnt air G21, and flows upward into the second-stage regeneration zone to continue regeneration. The specific operation is carried out. , the temperature and carbon content of the first-stage regeneration are controlled according to the amount of catalyst introduced into the first-stage regeneration zone and the amount of charred air G21, and the temperature of the second-stage regeneration is controlled according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com