Nuclear power station radioactive waste gas treatment method

A technology for waste gas treatment and radioactive gas, used in radioactive purification, nuclear engineering and other directions, can solve the problems of safety to be improved, leakage of radioactive components, high operating pressure, and achieve the effect of reducing hydrogen content, reducing radioactive concentration, and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

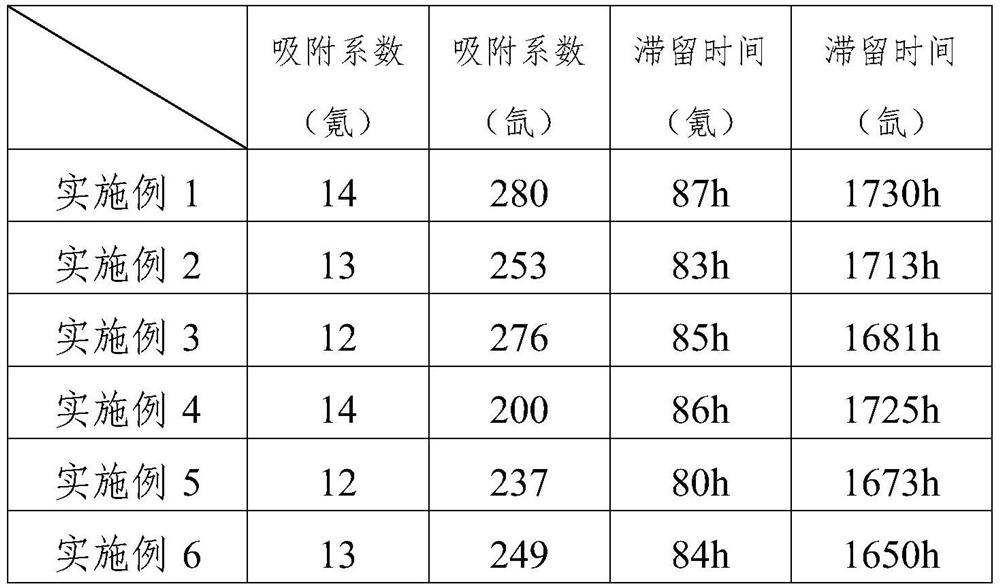

Embodiment 1

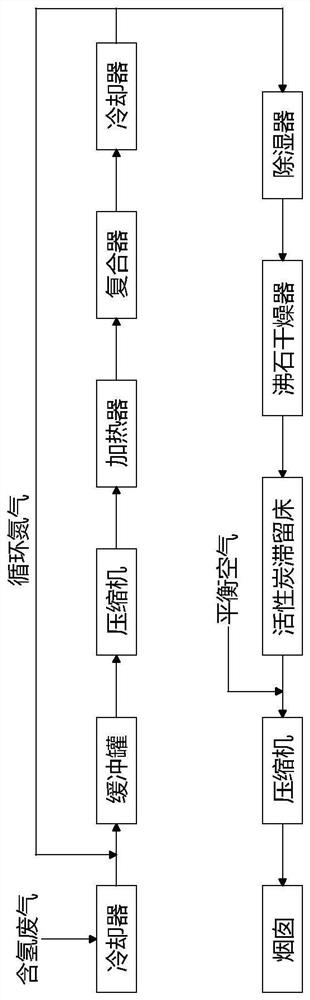

[0031] A method for treating radioactive waste gas from a nuclear power plant, comprising the following steps:

[0032] (1) Catalytic oxidation composite advanced treatment:

[0033] 1a) After the gas-vapor mixture from the degasser, pressure relief box and coolant leakage collection box of the chemical volume system is condensed and dehumidified by the cooler, the remaining non-condensable gas is dehumidified with 234Nm 3 / h circulating nitrogen dilution, so that the hydrogen content in the exhaust gas does not exceed 2.5%;

[0034] 1b) After the diluted hydrogen-containing waste gas enters the buffer tank, it is evenly mixed with the added oxygen;

[0035] 1c) The mixed gas enters the recombiner after being heated to 140°C by a heater;

[0036] 1d) When the exhaust gas passes through the recombiner, hydrogen and oxygen are recombined into water at 350°C under the catalysis of platinum oxide, so that the hydrogen content in the residual gas does not exceed 0.2%;

[0037] 1...

Embodiment 2

[0042] A method for treating radioactive waste gas from a nuclear power plant, comprising the following steps:

[0043] (1) Catalytic oxidation composite advanced treatment:

[0044] 1a) After the gas-vapor mixture from the degasser, pressure relief box and coolant leakage collection box of the chemical volume system is condensed and dehumidified by the cooler, the remaining non-condensable gas is dehumidified with 220Nm 3 / h circulating nitrogen dilution, so that the hydrogen content in the exhaust gas does not exceed 2.5%;

[0045] 1b) After the diluted hydrogen-containing waste gas enters the buffer tank, it is evenly mixed with the added oxygen;

[0046] 1c) The mixed gas enters the recombiner after being heated to 130°C by a heater;

[0047] 1d) When the exhaust gas passes through the recombiner, hydrogen and oxygen are recombined into water at 380°C under the catalysis of platinum oxide, so that the hydrogen content in the residual gas does not exceed 0.2%;

[0048]1e...

Embodiment 3

[0053] A method for treating radioactive waste gas from a nuclear power plant, comprising the following steps:

[0054] (1) Catalytic oxidation composite advanced treatment:

[0055] 1a) After the gas-vapor mixture from the degasser, pressure relief box and coolant leakage collection box of the chemical volume system is condensed and dehumidified by the cooler, the remaining non-condensable gas is dehumidified with 200Nm 3 / h circulating nitrogen dilution, so that the hydrogen content in the exhaust gas does not exceed 2.5%;

[0056] 1b) After the diluted hydrogen-containing waste gas enters the buffer tank, it is evenly mixed with the added oxygen;

[0057] 1c) The mixed gas enters the recombiner after being heated to 150°C by a heater;

[0058] 1d) When the exhaust gas passes through the recombiner, hydrogen and oxygen are recombined into water at 320°C under the catalysis of platinum oxide, so that the hydrogen content in the residual gas does not exceed 0.2%;

[0059] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com