Thixotropic agent and two-component silicone sealant containing thixotropic agent

A technology of silicone sealant and thixotropic agent, applied in the field of materials, can solve problems such as poor extrudability of silicone sealant, and achieve the effect of improving extrudability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The raw materials for the preparation of component B include the following components in parts by weight: diluent: 100 parts, organopolysiloxane polymer: 10-100 parts, reinforcing filler: 20-60 parts, cross-linking agent: 10 parts Parts to 100 parts; Coupling agent: 5 parts to 50 parts, Catalyst: 0.1 parts to 10 parts.

[0030] The basic effect of using this range is good extrusion, easy construction, and moderate mechanical properties.

[0031] Further, in the two-component silicone sealant A component, the content of the thixotropic agent accounts for 0.06% to 1% by weight of the A component. The presented properties are better.

[0032] Further, component A: organopolysiloxane polymer: 100 parts, plasticizer: 35 parts to 45 parts, filler: 40 parts to 60 parts, thixotropic agent: 1 part to 2 parts;

[0033] Component B: diluent: 100 parts, organopolysiloxane polymer: 30-50 parts, reinforcing filler: 40-60 parts, cross-linking agent: 35-50 parts; coupling agent: 15 p...

Embodiment 1

[0054] Thixotropic preparation

[0055] Preparation method: Add ethyl acetate, hydrogen-containing silicone oil, and ethylene glycol monoallyl ether into the mixer according to the parts by weight in Table 1 and stir, add chloroplatinic acid after 10 minutes, and remove ethyl acetate and Thixotropic agents are obtained after small molecules.

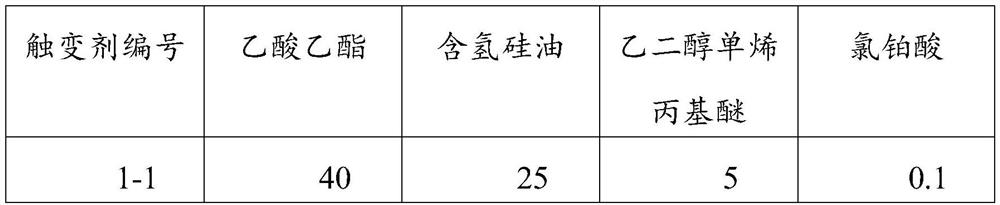

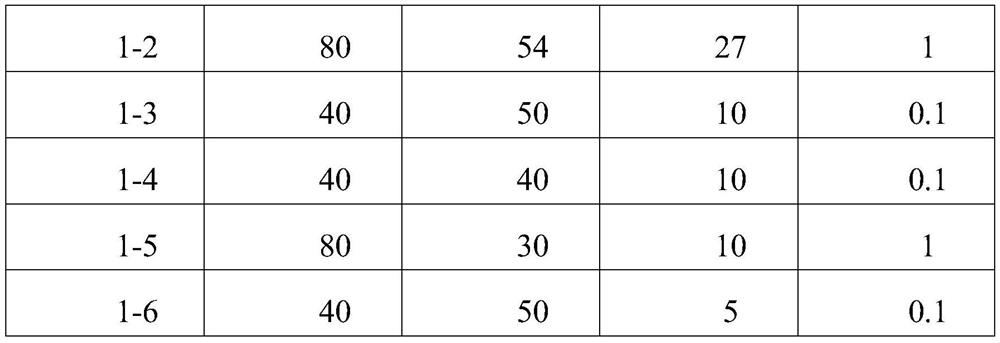

[0056] The preparation raw material of table 1 thixotropic agent

[0057]

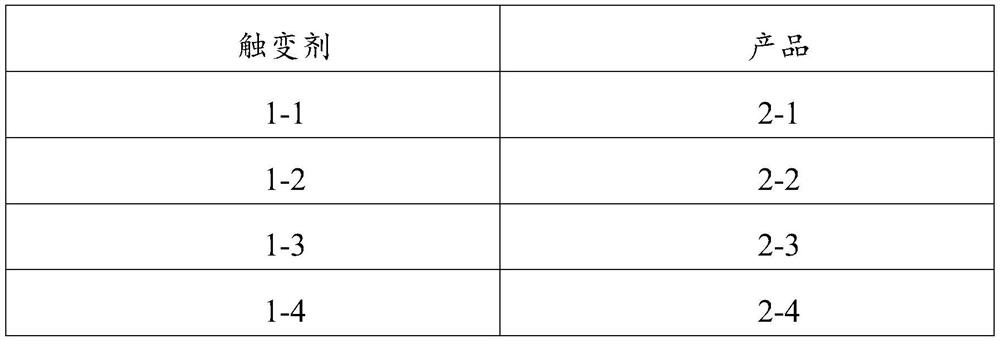

[0058]

Embodiment 2

[0060] Use thixotropic agent in embodiment 1 to prepare two-component silicone sealant

[0061] The preparation method is as follows:

[0062] Preparation of component A: 100 parts by weight of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2000mPa·s at 25°C, 0.1 part by weight of a thixotropic agent, 20 parts by weight of nano-calcium carbonate, and a viscosity of 50mPa·s Add 20 parts by weight of simethicone oil into a kneader, knead at 40°C for 30 minutes, and discharge after cooling to obtain component A.

[0063] Preparation of component B: in a planetary machine, add 100 parts by weight of simethicone oil with a viscosity of 1000mPa·s at 25°C, and add α, ω-dihydroxy polydimethylsiloxane in portions under the state of nitrogen gas 25 parts by weight of alkane, 20 parts by weight of white carbon black, 10 parts by weight of methyltrimethoxysilane, 5 parts by weight of γ-glycidyl etheroxypropyl trimethoxysilane, 0.1 part by weight of dibutyltin dilaurate, after mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com