Composite material and preparation method thereof

A composite material and compound technology, applied in the field of materials, can solve problems such as poor luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

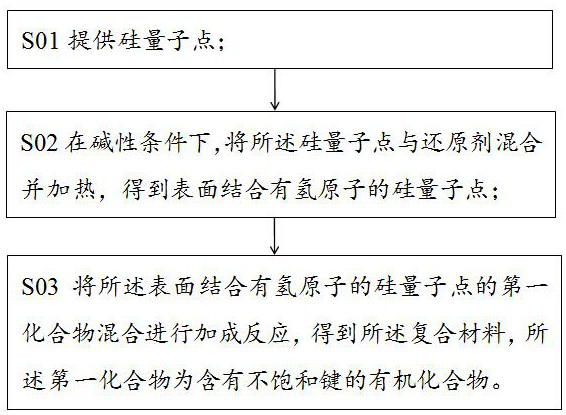

[0035] like figure 1 Shown, in some embodiments, the preparation method of described composite material, comprises the steps:

[0036] S01 provides silicon quantum dots;

[0037] S02 Under alkaline conditions, the silicon quantum dots are mixed with a reducing agent and heated to obtain silicon quantum dots with hydrogen atoms bound to the surface;

[0038] S03 Mixing the first compound of the silicon quantum dots with hydrogen atoms bound to the surface for an addition reaction to obtain the composite material, the first compound is an organic compound containing an unsaturated bond.

[0039] In some embodiments, in the step S01, the silicon quantum dots are silicon quantum dots prepared by existing methods, for example, in some specific embodiments, the silicon quantum dots are synthesized by a hydrothermal method.

[0040] In some embodiments, in the step S02, the silicon quantum dots are mixed with a reducing agent and heated at a pH of 10-12 to obtain silicon quantum do...

Embodiment 1

[0082] Silicon quantum dots were synthesized by the hydrothermal method. A certain amount of silicon quantum dots was put into an agate mortar and ground for several hours to obtain silicon powder with a very small particle size. Then 200 mg was weighed and added to a hydrothermal reaction kettle. Add 40 mL of deionized water, adjust the pH to 10 with NaOH, add 0.4 g of NaBH 4 ,seal. Put the reaction kettle into a constant temperature oven, raise the temperature to 200°C, and react for 5 hours. After the reaction was completed, it was naturally cooled to room temperature to obtain a colorless and clear solution. Then filter to remove solid impurities, collect the filtrate, add it to a 250 mL round bottom flask, and use a vacuum rotary evaporator to remove the water, and the obtained solid powder is hydrogen atom passivated silicon quantum dots;

[0083] Take 80 mg hydrogen atom passivated silicon quantum dot powder and add it to a 20 mL round bottom flask, then add 3 mL of a...

Embodiment 2

[0085] Silicon quantum dots were synthesized by the hydrothermal method. A certain amount of silicon quantum dots was put into an agate mortar and ground for several hours to obtain silicon powder with a very small particle size. Then 200 mg was weighed and added to a hydrothermal reaction kettle. Add 40 mL of deionized water, adjust the pH to 11 with NaOH, add 0.6 g of NaBH 4 ,seal. Put the reaction kettle into a constant temperature oven, raise the temperature to 210°C, and react for 7 hours. After the reaction was completed, it was naturally cooled to room temperature to obtain a colorless and clear solution. Then filter to remove solid impurities, collect the filtrate, add it to a 250 mL round bottom flask, and use a vacuum rotary evaporator to remove the water, and the obtained solid powder is hydrogen atom passivated silicon quantum dots;

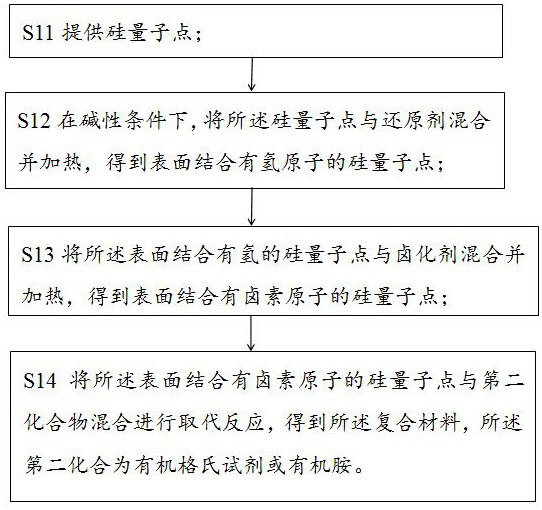

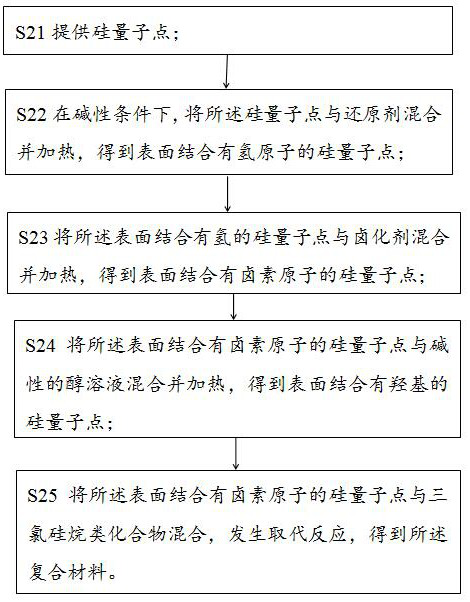

[0086] Take 100 mg of silicon quantum dots passivated by hydrogen atoms and disperse them in 10 ml of water, add 1 mL of 5% I2 alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com