Nano-material antibacterial mask and preparation method thereof

A technology of nanomaterials and masks, which is applied in the field of nanomaterial antibacterial masks and its preparation, and can solve problems such as poor filtering effect of mask filter materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

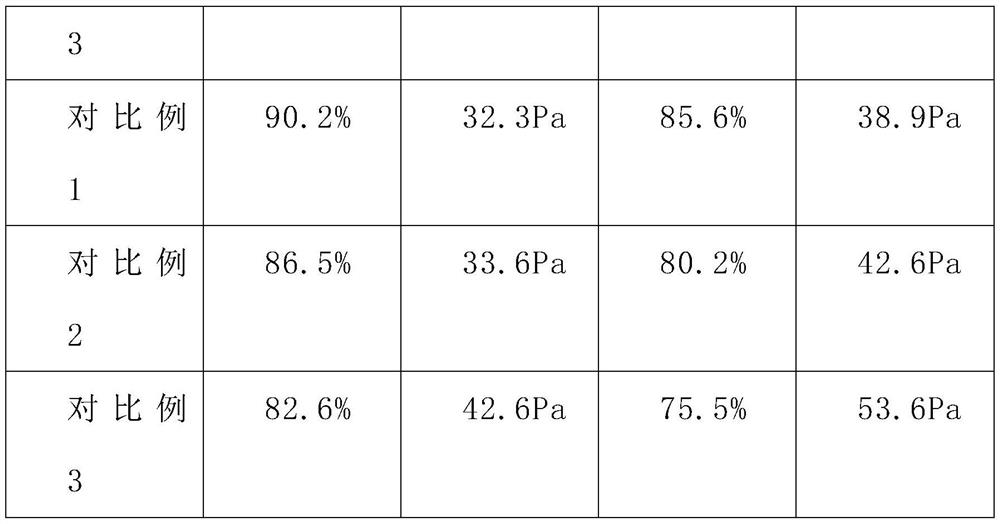

Examples

preparation example Construction

[0018] A preparation method of a nanomaterial antibacterial mask, the specific preparation steps comprising:

[0019] Preparation of modified graphene oxide: in parts by weight, successively take 10-20 parts of graphene oxide, 80-100 parts of absolute ethanol, 10-20 parts of fatty acid, and 8-10 parts of titanate; After mixing ene, absolute ethanol, fatty acid and titanate, ultrasonically disperse evenly, and then heat and reflux for reaction, suction filter, wash and dry to obtain modified graphene oxide.

[0020] Further, the titanate is any one of tetramethyl titanate, tetraethyl titanate or tetrabutyl titanate.

[0021] Further, the specific preparation steps include:

[0022] The treatment of bamboo charcoal fiber: impregnating bamboo fiber with a water content of 20-40% in absolute ethanol, and adding silicate with a mass of bamboo fiber of 10-15%, after heating and stirring to react, filter, wash and dry to obtain pre- Treat the bamboo fiber; then slowly heat up the p...

Embodiment 1

[0026] Preparation of modified graphene oxide: in parts by weight, successively take 10 parts of graphene oxide, 80 parts of absolute ethanol, 10 parts of fatty acid, and 8 parts of titanate; first prepare graphene oxide, absolute alcohol, fatty acid and After the titanate is mixed, it is ultrasonically dispersed for 50 minutes at an ultrasonic frequency of 40 kHz, and then heated and refluxed for 3 hours at a temperature of 80° C., then suction filtered, washed and dried to obtain modified graphene oxide; the titanium The ester is tetramethyl titanate;

[0027] The treatment of bamboo charcoal fiber: impregnating the bamboo fiber with a moisture content of 20% in absolute ethanol, and adding silicate with 10% of the bamboo fiber mass, heating and stirring for reaction, filtering, washing and drying to obtain pretreated bamboo fiber; Then, under the protection of inert gas, the pretreated bamboo fiber is heated to 400°C at a rate of 1.5°C / min, and then to 1000°C at a rate of 0...

Embodiment 2

[0031] Preparation of modified graphene oxide: in parts by weight, successively take 15 parts of graphene oxide, 90 parts of absolute ethanol, 15 parts of fatty acid, and 9 parts of titanate; first, graphene oxide, absolute alcohol, fatty acid and After the titanate is mixed, the ultrasonic dispersion is uniform, and after heating and reflux reaction, the modified graphene oxide is obtained by suction filtration, washing and drying; the titanate is tetraethyl titanate;

[0032] The treatment of bamboo charcoal fiber: impregnating bamboo fiber with a moisture content of 30% in absolute ethanol, and adding silicate with 12% of bamboo fiber mass, heating and stirring for reaction, filtering, washing and drying to obtain pretreated bamboo fiber; Then, under the protection of inert gas, the pretreated bamboo fiber is heated to 450°C at a rate of 1.8°C / min, and then to 1100°C at a rate of 0.5°C / min. Bamboo charcoal fiber; The silicate is ethyl silicate;

[0033] Preparation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com