Metal-loaded cerium-zirconium solid solution material, preparation method thereof and application of metal-loaded cerium-zirconium solid solution material in catalytic synthesis of carvone

A cerium zirconium solid solution and metal-loaded technology, which is applied in the field of catalysis and can solve problems such as large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of cerium-zirconium solid solution loaded with metal cobalt

[0036]Dissolve 4.364g of cerium nitrate hexahydrate, 2.336g of zirconium oxynitrate, 8.406g of citric acid and cobalt nitrate hexahydrate in distilled water, stir until the solution is clear, then add absolute ethanol to obtain a precursor solution, foam overnight at 90°C, Calcined at 500°C for 4h; Ce 0.5 Zr 0.5 o 2 / Co.

[0037] The steps of loading metal In, Cd, Mn, Zn, Cr, Ni or Al on the cerium-zirconium solid solution are the same as above. The metal loading molar ratio was 5%.

Embodiment 2

[0038] Embodiment 2: Preparation of cerium-zirconium solid solution loaded with metal indium

[0039] According to the steps of Example 1, using InCl 3 .4H 2 O as the precursor of metal indium to prepare supported metal indium is a solid solution of cerium and zirconium. The amount of precursor was changed to prepare materials with molar ratios of 1%, 5%, 10%, 15%, and 20% metal indium supported on cerium-zirconium solid solution, respectively.

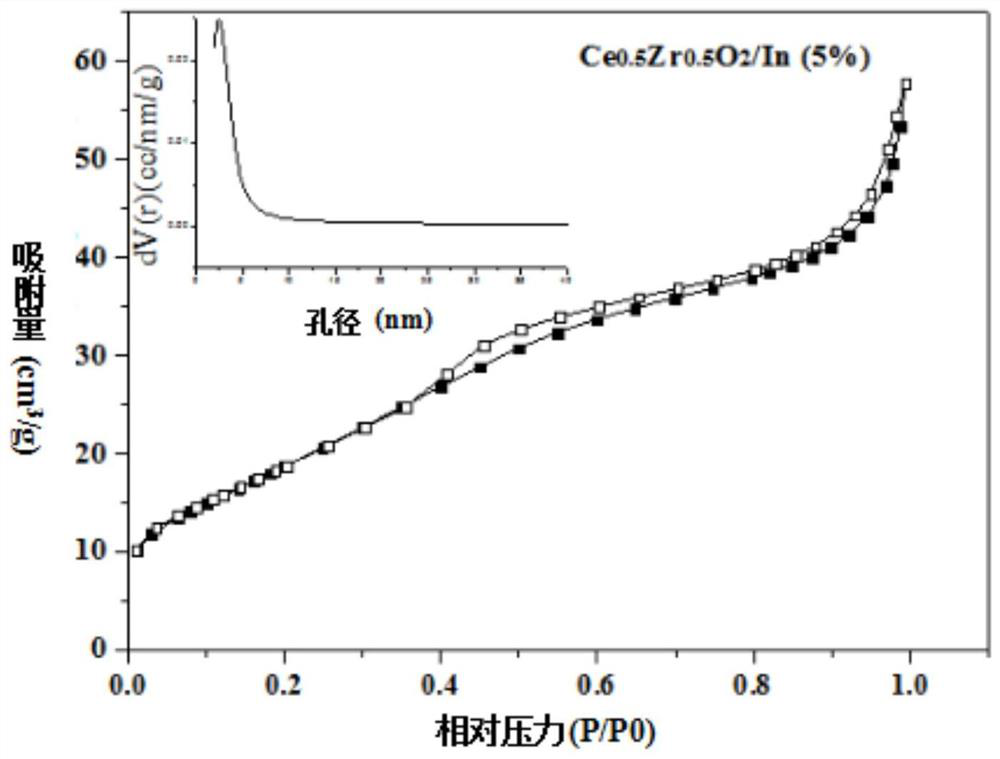

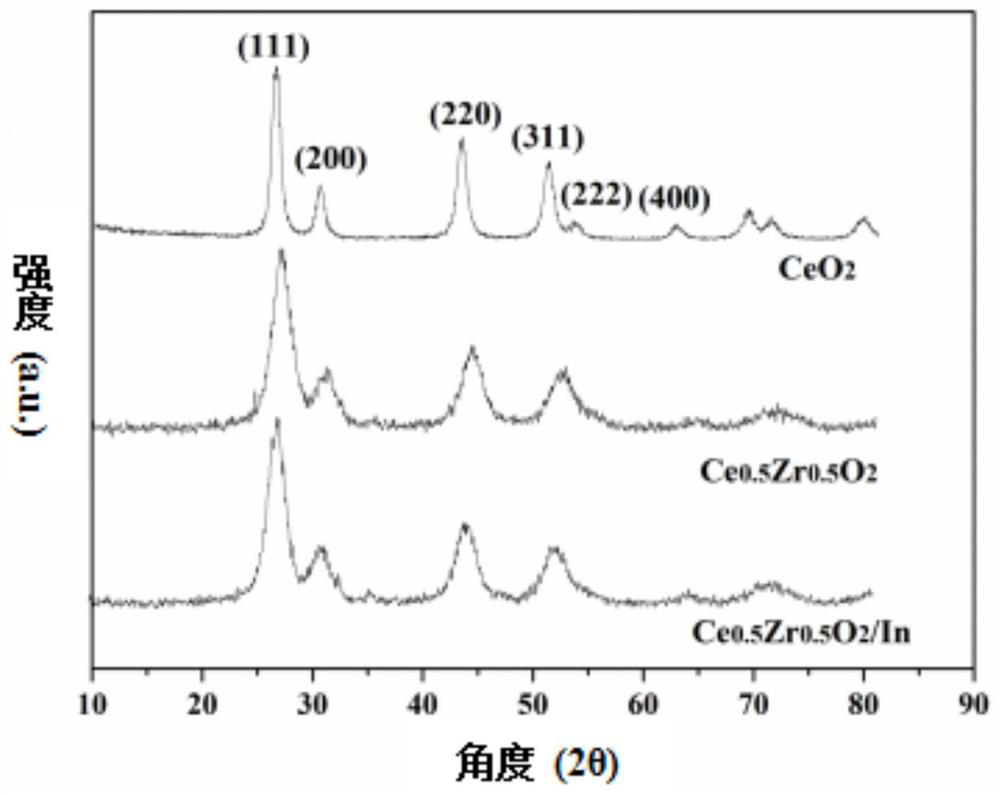

[0040] figure 1 and figure 2 is to obtain Ce 0.5 Zr 0.5 o 2 / In(5%) (that is, indium with a loading molar ratio of metal indium of 5%) material characterization results. From figure 1 It can be seen that Ce 0.5 Zr 0.5 o 2 / In (5%) meets the criteria for mesoporous materials. From figure 2 It can be seen that the cerium-zirconium solid solution loaded with metal indium does not change the material structure significantly, and the material Ce 0.5 Zr 0.5 o 2 / In(5%) and material CeO 2 The peak shape is also very consis...

Embodiment 3

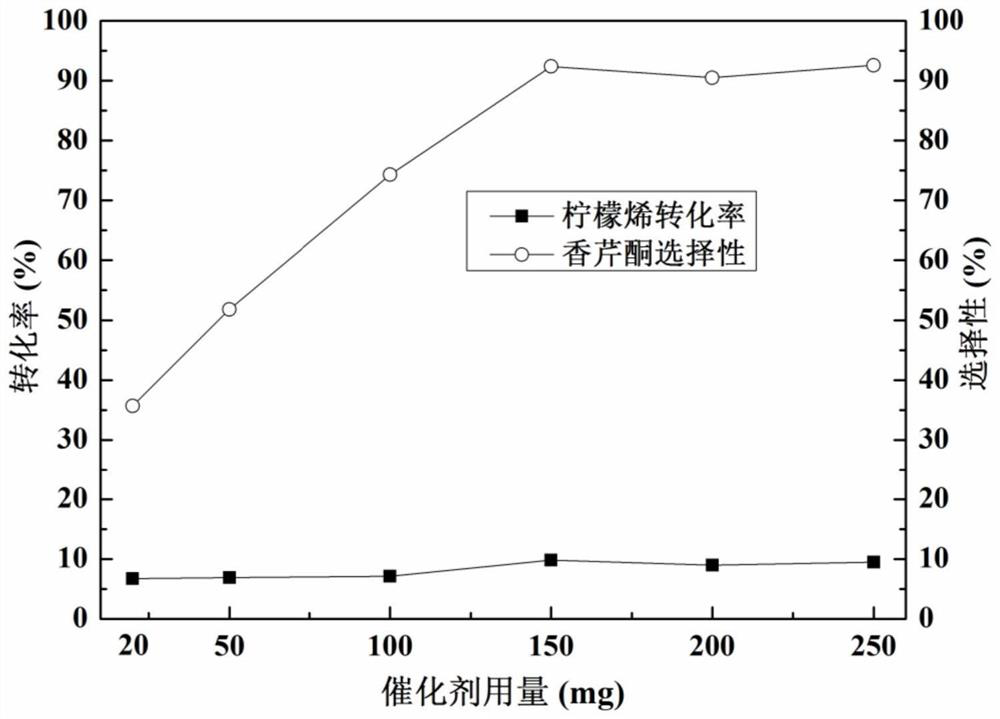

[0041] Example 3: The metal-loaded cerium-zirconium solid solution material is used as a catalyst to catalyze the oxidation of limonene to prepare carvone. The reaction steps are as follows:

[0042] Take 2mL of R-(+)-limonene and 150mg of catalyst into a 25mL two-necked flask, add 5g of acetic acid as a solvent, connect the flask to a condenser, and put it into an oil bath with magnetic stirring at a temperature of 80°C Inside, unscrew and stir, feed 1.8L / min air as an oxidant, and the reaction time is 12h. After the reaction time is completed, take out the flask, and after the reaction solution is cooled, filter out the catalyst, and dry the sample solution with anhydrous magnesium sulfate. Finally, filter and analyze the sample qualitatively and quantitatively by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com