A kind of silicon-phosphorus synergistic coal flame retardant and dust suppressant and preparation method thereof

A technology of silicon-based flame retardants and dust suppressants, applied in chemical instruments and methods, other chemical processes, anti-corrosion coatings, etc., can solve the problems of low flame retardant level, poor compression resistance, and dependence on imports of flame retardants, etc. Achieve the effect of improving flame retardant performance, prolonging dust suppression cycle and preventing coal dust from dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

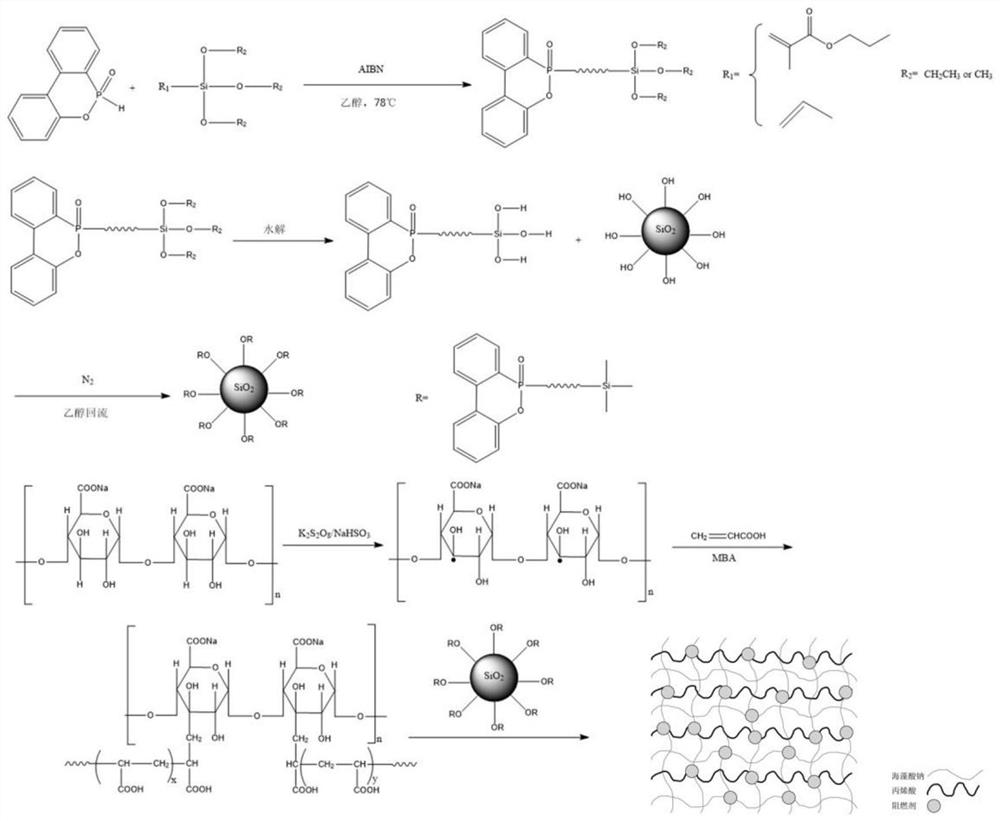

[0069] A preparation method of silicon-phosphorus synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0070] (1) Add 0.20g DOPO, 0.25g KH570 and 30.0g absolute ethanol to a three-necked flask filled with inert gas to obtain solution A;

[0071] Dissolve 0.014g of azobisisobutyronitrile in 10.0g of absolute ethanol to obtain solution B;

[0072] Add solution B to solution A dropwise for 30 minutes, then react in an oil bath at 75°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame retardant intermediate.

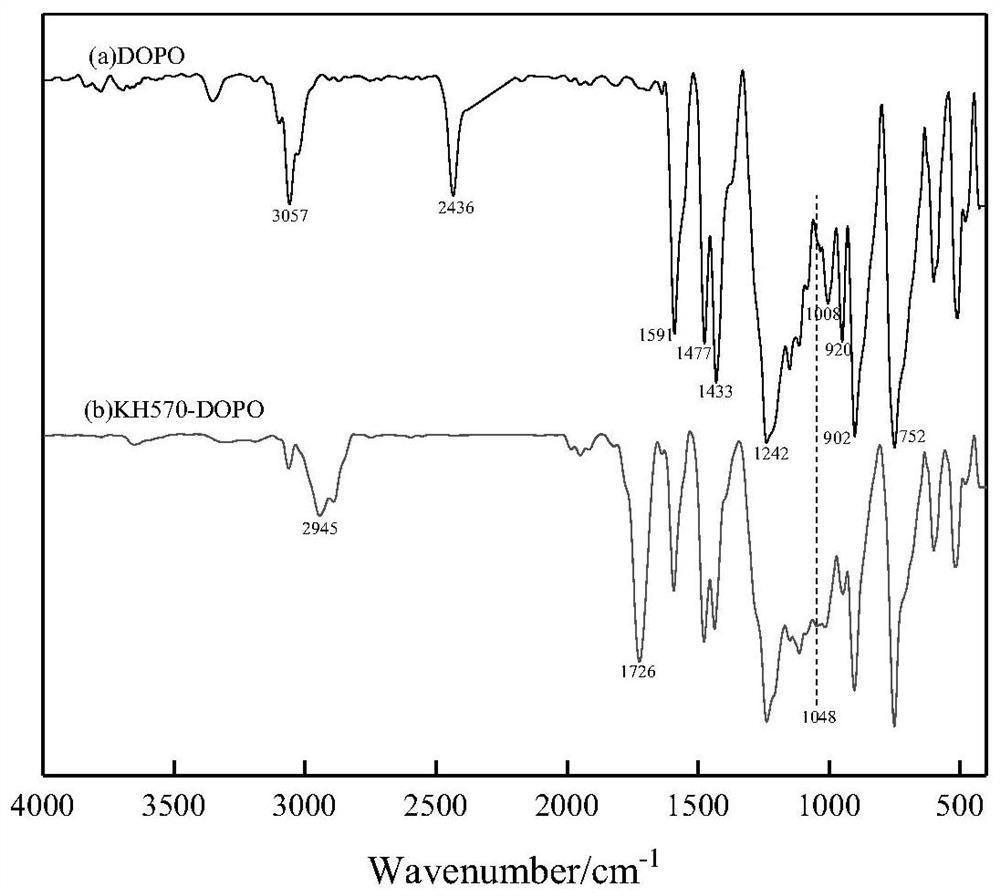

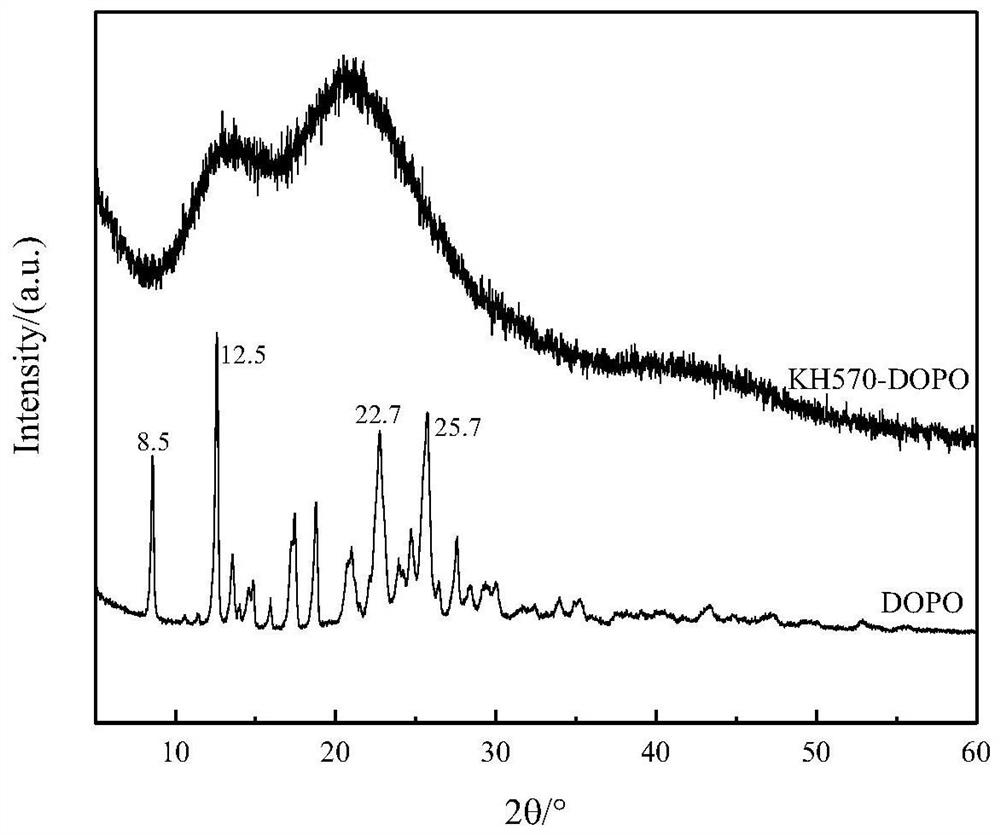

[0073] The reaction scheme is as follows figure 1 As shown, the active hydrogen on DOPO can undergo free radical addition reaction with the double bond on KH570, and the catalyst azobisisobutyronitrile is added to accelerate the reaction, and the flame retardant intermediate is obtained from the reaction. The catalyst cannot be added too fast, otherwise it is ...

Embodiment 2

[0084] A preparation method of silicon-phosphorus synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0085] (1) Add 0.20g DOPO, 0.30g KH570 and 50.0g toluene into a three-necked flask filled with inert gas to obtain solution A;

[0086] Dissolve 0.015g of azobisisobutyronitrile in 10.0g of toluene to obtain solution B;

[0087] Add solution B dropwise to solution A for 40 minutes, then react in an oil bath at 120°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame retardant intermediate;

[0088] (2) Add a flame retardant intermediate to a beaker, add 57.0 g of ethanol and 3.0 g of deionized water to the flame retardant intermediate, add 0.12 g of acetic acid to adjust the pH to 4.0, and ultrasonically hydrolyze for 2 hours to obtain solution C;

[0089] Then transfer to a three-necked flask with an inert gas, add 50.0g parts of absolute ethanol, 0.20g nanomete...

Embodiment 3

[0096] A preparation method of silicon-phosphorus synergistic coal flame retardant and dust suppressant, comprising the following steps:

[0097] (1) Add 0.15g DOPO, 0.20g KH570, and 50.0g toluene into a three-necked flask filled with inert gas to obtain solution A;

[0098] Dissolve 0.011g of azobisisobutyronitrile in 10.0g of toluene to obtain solution B;

[0099] Add solution B dropwise to solution A for 40 minutes, then react in an oil bath at 120°C for 12 hours to obtain a crude product, remove the solvent by rotary evaporation, and then dry it for 24 hours to obtain a flame retardant intermediate;

[0100] (2) Add a flame retardant intermediate to a beaker, add 57.0 g of ethanol and 3.0 g of deionized water to the flame retardant intermediate, add 0.12 g of acetic acid to adjust the pH to 4.0, and ultrasonically hydrolyze for 2 hours to obtain solution C;

[0101] Then transfer to a three-necked flask with an inert gas, add 50.0g of absolute ethanol and 0.20g of kaolin,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com