Normal-temperature fresh keeping method of fresh wet instant rice noodles

A fresh-keeping method and rice noodle technology, applied in food preservation, food science, ultra-high pressure food processing, etc., can solve the problems of poor equipment, sourness, poor sanitation, etc., to inhibit growth and reproduction, inactivate enzyme activity, solve The effect of a short shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

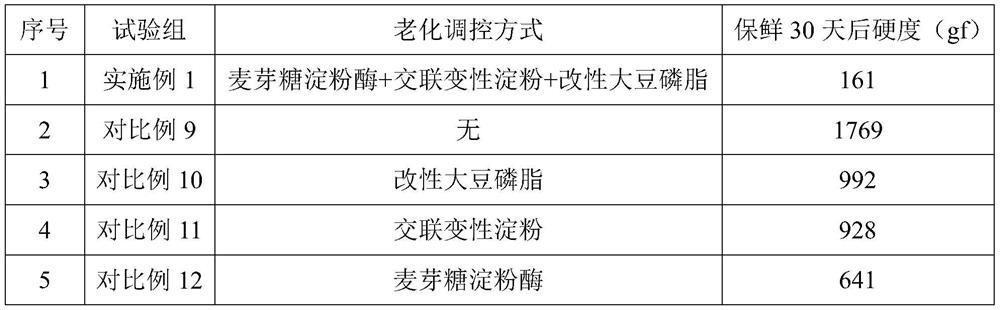

[0035] A method for preparing instant fresh-keeping rice noodles at normal temperature. The instant rice noodles fresh-keeping at normal temperature comprise the following raw materials in parts by weight: 32 parts of indica rice flour, 10 parts of japonica rice flour, 40 parts of cornstarch, 1 part of cake flour, 1 part of cross-linked starch, compounded 0.1 part of antistaling agent, 0.06 part of modified soybean lecithin, 0.01 part of maltogenic amylase (enzyme activity 6000U / g), 30 parts of purified water. Among them, the particle size of indica rice flour and japonica rice flour is 80 mesh, and the cake powder is cooked indica rice flour; the compound preservative is made of sodium dehydroacetate, propylene glycol and citric acid, and the mass ratio of the three is 4:1:10 .

[0036] The preparation method comprises the following steps:

[0037] S1. Enzymolysis: Weigh indica rice flour, japonica rice flour and cake powder, mix them evenly, take 20 parts of them and put th...

Embodiment 2

[0048] A method for preparing instant rice noodles kept fresh at room temperature, wherein the instant rice noodles kept fresh at room temperature comprise the following raw materials in parts by weight: 40 parts of indica rice flour, 15 parts of japonica rice flour, 50 parts of cornstarch, 3 parts of cake powder, 3 parts of cross-linked starch, compounded 0.3 parts of antistaling agent, 0.08 parts of modified soybean lecithin, 0.03 parts of maltogenic amylase (enzyme activity 6000U / g), 40 parts of purified water.

[0049] The composite antistaling agent comprises 0.08 part of sodium dehydroacetate, 0.05 part of propylene glycol and 0.2 part of citric acid in mass ratio. Both the indica rice flour and the japonica rice flour have a particle size of 100 mesh. Cake flour is cooked indica rice flour.

[0050] Concrete preparation method comprises the following steps:

[0051] S1. Enzymolysis: Weigh indica rice flour, japonica rice flour and cake powder, mix them evenly, take 30...

Embodiment 3

[0062] A method for preparing instant fresh-keeping rice noodles at normal temperature, the instant rice noodles fresh-keeping at normal temperature, comprising the following raw materials in parts by weight: 48 parts of indica rice flour, 18 parts of japonica rice flour, 60 parts of cornstarch, 5 parts of cake powder, 5 parts of cross-linked starch, 0.5 parts of compound antistaling agent, 0.12 parts of modified soybean lecithin, 0.05 parts of maltogenic amylase (enzyme activity 6000U / g), 50 parts of purified water.

[0063] The composite antistaling agent comprises 0.1 part of sodium dehydroacetate, 0.08 part of propylene glycol and 0.4 part of citric acid in mass ratio. Both the indica rice flour and the japonica rice flour have a particle size of 120 mesh. Cake flour is cooked indica rice flour.

[0064] Concrete preparation method comprises the following steps:

[0065] S1. Enzymolysis: Weigh indica rice flour, japonica rice flour and cake powder, mix them evenly, take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com